49

3062547_201802

31 CO

2

check/adjustmentbymatching

thepipelengths

CO

2

adjustmentby

matchingthepipelengths

HG 00 CO

2

adjustments

Factory setting: 3

1 2 3 4 5

Lower CO

2

valueHigher CO

2

value

WithcontractorparameterHG00(seechapter19"Contractorlevelparameters"),

theappliancescanbematchedtotheuesystembychangingthespeedfor

bothstagesandthereforetheCO

2

valuecanbechanged.

- Remove front and top casing.

- Remove the cap from the r.h. "ue gas" test port.

- Insert the test probe of the CO

2

measuring instrument into the "ue gas" test port

(approx. 70 mm).

- Turn the program selector switch on the BM module to "Emissions test" .

(Illuminated signal ring as status indicator ashes yellow.)

- Measure the CO

2

content and compare it against the values given in the stage 2 table

below.

- If required, alter the CO

2

content with parameter HG00.

- Modifying the parameter HG00 has also adjusted the speed for stage 1. For

checking purposes, the boiler must be set to stage 1.

- Switch HG28 burner operating mode from 2(two-stage) to 1(single stage).

- Measure the CO

2

content and compare it against the values given in the stage 1

table below.

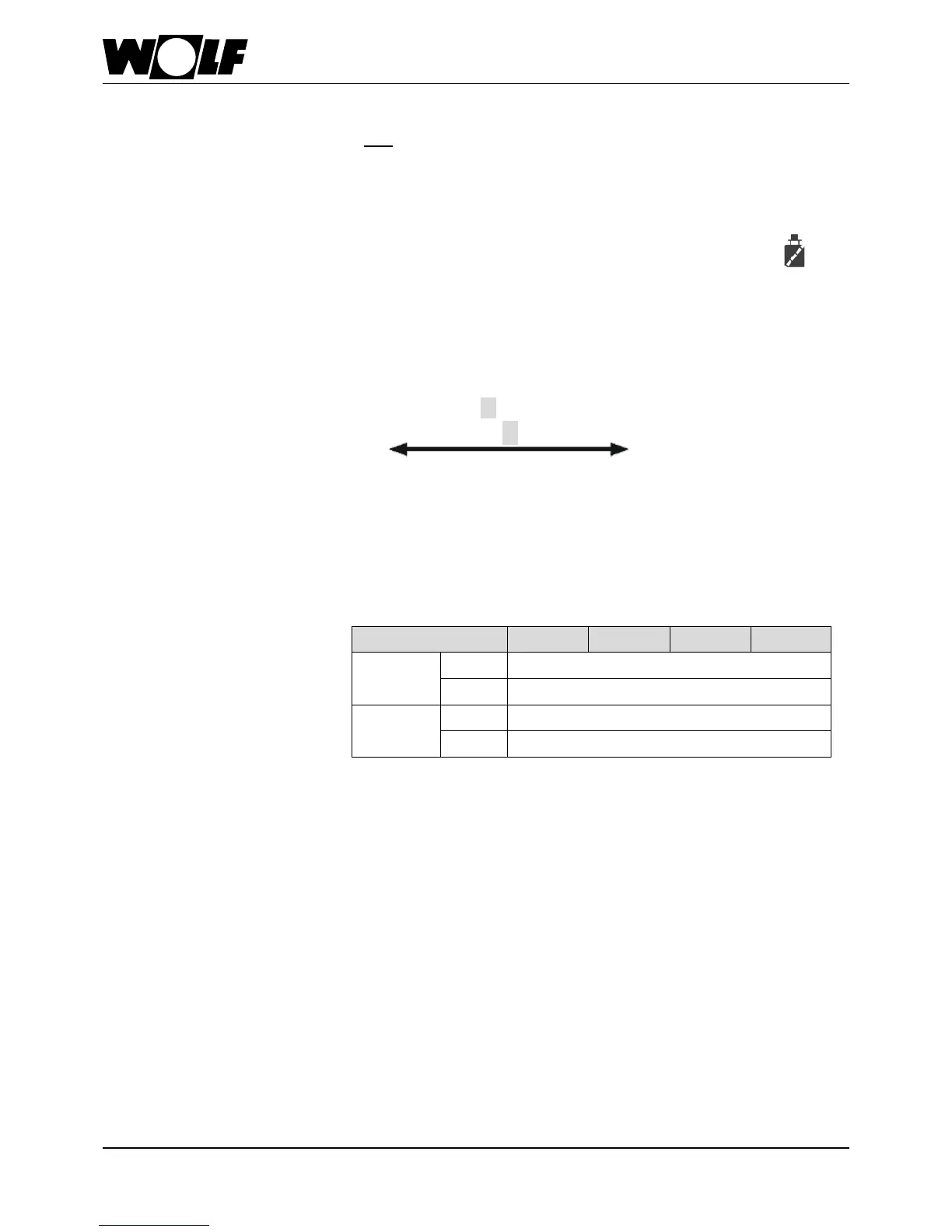

Appliance open COB-15 COB-20 COB-29 COB-40

Set CO

2

value

Stage 2 12,7 ± 0,3%

Stage 1 12,7 ± 0,3%

O

2

set value

Stage 2 3,8 ± 0,4%

Stage 1 3,8 ± 0,4%

- If the value lies outside of the set value, the CO

2

-value must be set

via the pump pressure (see Commissioning without Wolf control accessories).

- Reset HG28 burner operating mode from 1 to 2.

CO

2

check/settinginthelower

load(stage1)

AdjustingtheCO

2

valueinthe

upperloadrange(stage2)

(emissionstestmode)

Loading...

Loading...