45

3062547_201802

Programmable

Output A1

(230VAC; 200VA)

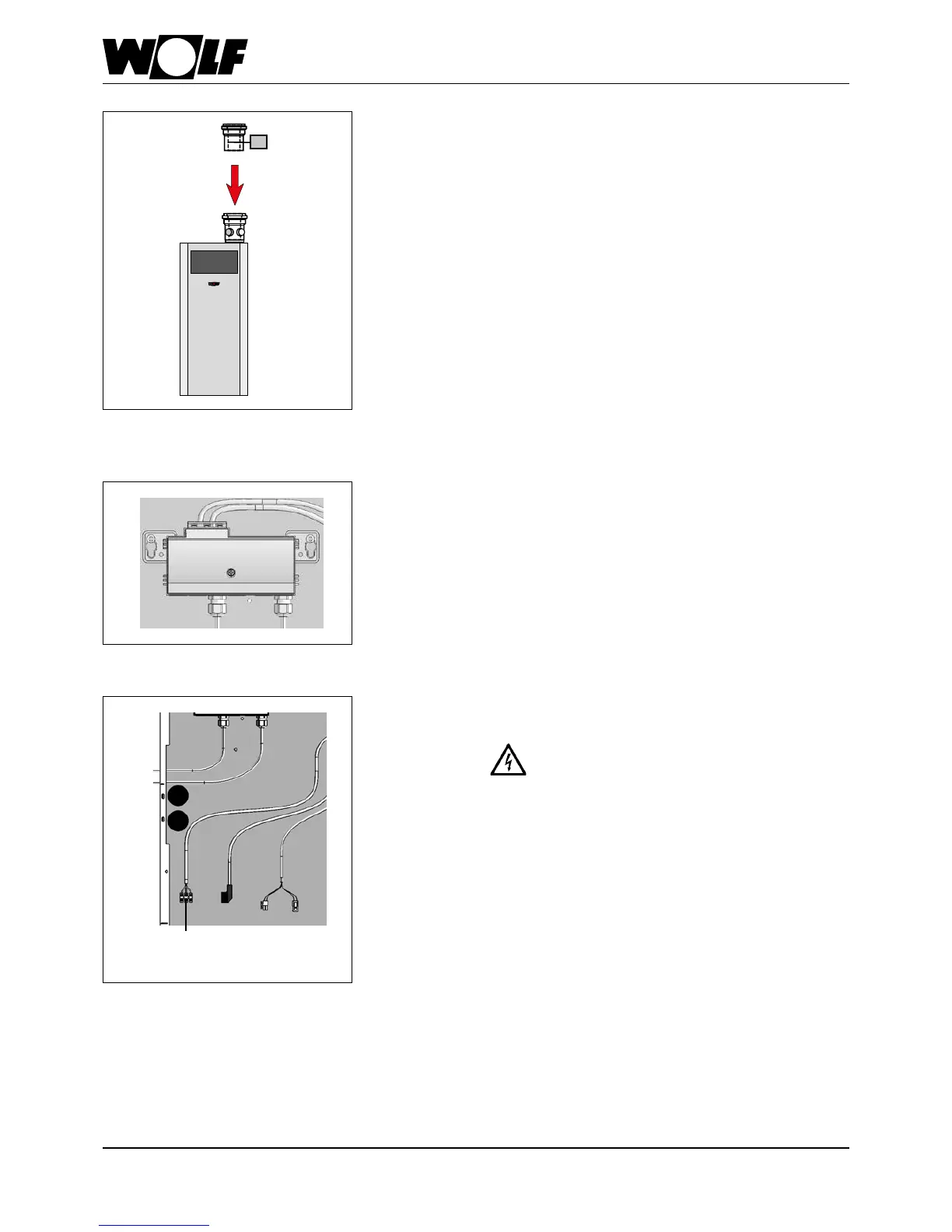

COB back view

Installation information on the E1 input electrical

connectionA1outputforuegasdamper

Nevertouchelectricalcomponentsor

contactswhentheON/OFFswitchisintheON

position.Thereisadangerofelectrocution,

resultinginarisktohealthordeath.Themain

terminalsare'live',evenwhentheON/OFF

switchisintheOFFposition.

- Isolate the system from the power supply before opening.

- Unclip the terminal box from the holder.

- Open the terminal box.

- Screw the strain relief into the holes provided.

- Strip approx. 70 mm off the power cable from the limit switch.

- Push the cable through the strain relief and tighten the strain

relief.

- Connect the wires from the limit switch to input E1

(see the chapter "Wiring diagram cascade operation").

- Connect motor cable from the ue gas damper via an on-

site junction box with programmable output A1

(see the chapter "Wiring diagram cascade operation")

- Fit the cover.

Continue with the chapters “Flue gas damper tightness test”

and “Commissioning”

Terminal box

Electricalconnectioninstallationinformation

In the delivered condition, the terminal box is tted to the

back panel of the boiler.

If required, the terminal box can be mounted on the wall to

the right or left of the boiler, or above it.

The control and safety devices are fully wired and tested.

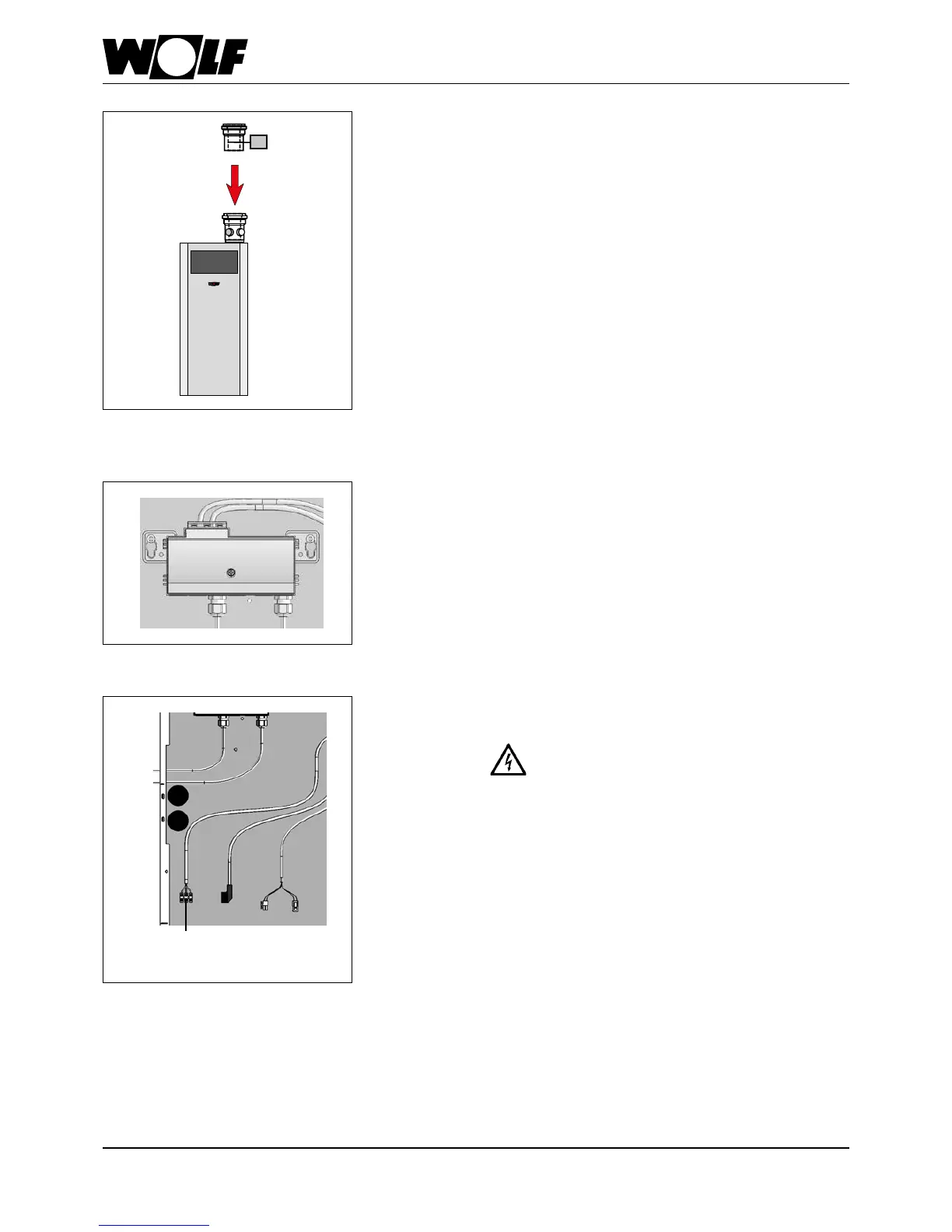

Mounting the ue gas damper

Flue gas

damper

COB

Fluegasdamperinstallationinformation

- Push ue gas damper as far as it will go onto connection

adaptor (with test nipple) on the boiler.

- Push the ue as far as it will go onto the ue gas damper

- Correctly route the limit switch cable and motor cable from

the ue gas damper to the terminal box and to the cable

(programmable output A1).

27 Cascadeoperation-Fluegas

damperinstallation

Loading...

Loading...