25

3062547_201802

18 Installationoftheair/uegas

routing

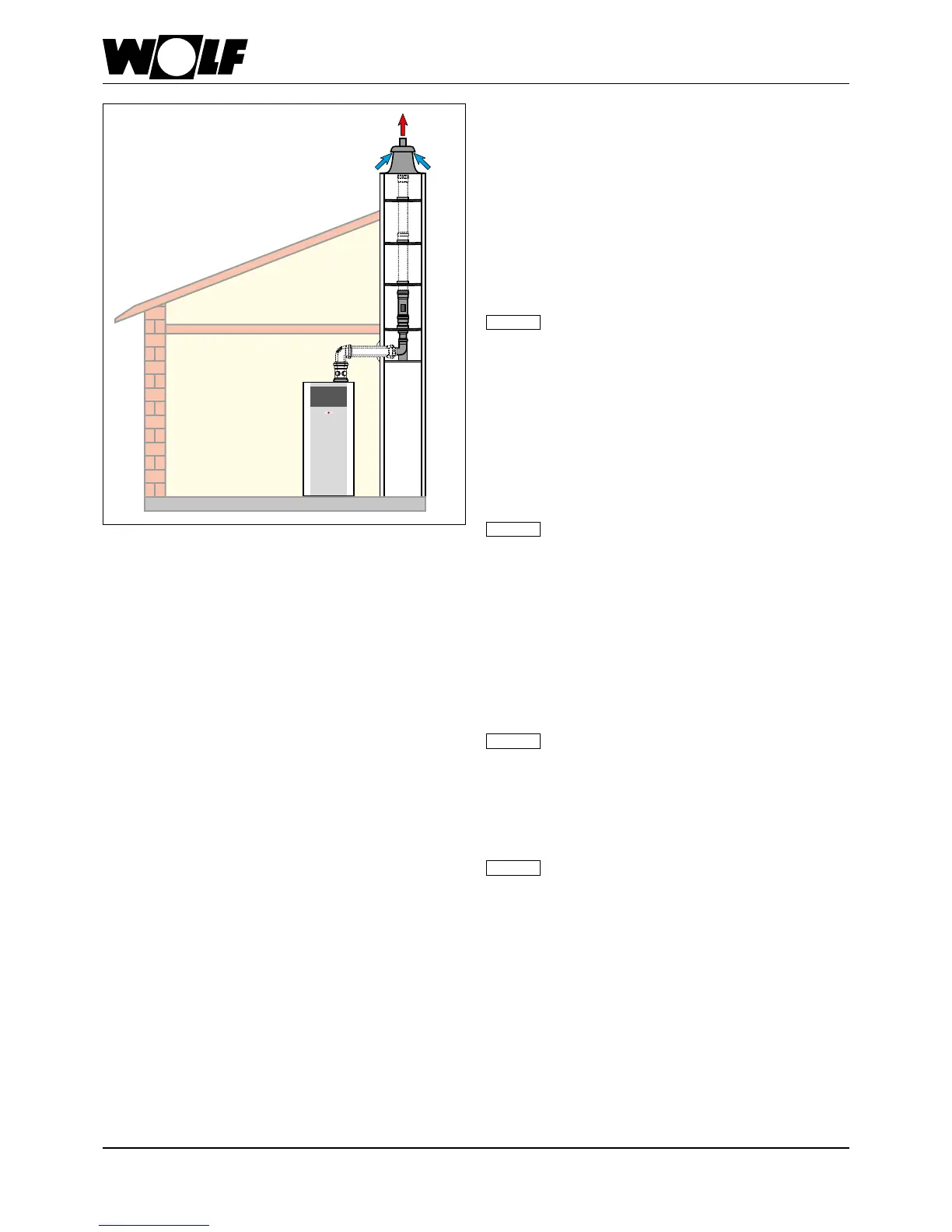

Fig.: Example of a C93x balanced ue system

UseonlyoriginalWolfcomponentsforuesandconcentric

balanceduesystems.

Observethetechnicalinformationregardingventilationair

supply/uesystemspriortoinstallingtheueormaking

theueconnection(seetheTechnicalInformationchapter)!

As regulations in the individual Federal States [Germany] differ,

we recommend consulting the relevant authorities and local ue

gas inspector prior to installation.

Between the ue terminal and the roof surface, there must be a

clearance of at least 0.4 m.

Flue connections are created using female connections and

gaskets. Always arrange female connections against the

direction of the condensate ow.

The balanced flue should be installed with a

slopeofatleast3°(6cm/m)totheoilcondensing

boiler.Fitspacerclipstosecuretheequipmentin

position.

Intheworstcasescenario,alesserslopeofthe

air/uegasroutingsystemmayleadtocorrosion

oroperatingfaults.

Alwaysbevelordeburrtrimmeduestoensure

gas-tight installation of pipe joints. Ensure

that gaskets are tted correctly. Remove all

contamination prior to installation - never t

damagedparts.

Note

Note

The local ue gas inspector must have clear

accesstotheuegastestnipples.

Note

ForCOB-15/-20/-29,thesuppliedfluegastest

nipplesmustbefittedtotheair/flueoutlets.

Alternatively, the flue gas test nipples may

also be directly fitted horizontally after the

87° bend fitted to the boiler. When doing

this,ensurethatthebalancedflueisrouted

over the appliance in such a way that

the displacement device can be removed

(minimumclearanceviaCOB-15/-20/-29is30

cm;forCOB-40itis40cm).

Note

Loading...

Loading...