52

3062547_201802

33 CO

2

check/adjustmentviapump

pressure

CO

2

settingsvia

pumppressure

If no control accessory is connected to the appliance or the CO

2

set value is

notachievedbymatchingthepipelengths,theCO

2

settingismadeviapump

pressurecontrol:

- Remove front and top casing.

- Pivot the control unit downwards.

- Insert the oil pressure gauge into the pump's pressure gauge test port.

- Remove the cap from the r.h. "ue gas" test port.

- Insert the test probe of the CO

2

measuring instrument into the "ue gas" test port (approx.

70 mm).

- Turn the heating water temperature selector to "Emissions test"

.

(illuminated signal ring as status indicator ashes yellow.)

- Measure the CO

2

content and compare it against the values given in the stage 2

table below.

- If required, amend the CO

2

content with the pressure regulating screw stage 2 with

a 4 mm Allen key (Danfoss design) or SW 8 open-ended spanner (Suntec design).

Turnclockwise-higherCO

2

value

Turnanti-clockwise-lowerCO

2

value

- Check whether the pump pressure is still within the tolerance range.

If not, then check the nozzle and mixer head.

- Terminate the emissions test mode by turning the DHW temperature selector back to

its original position.

AdjustingtheCO

2

valueinthe

upperloadrange(stage2)

(emissionstestmode)

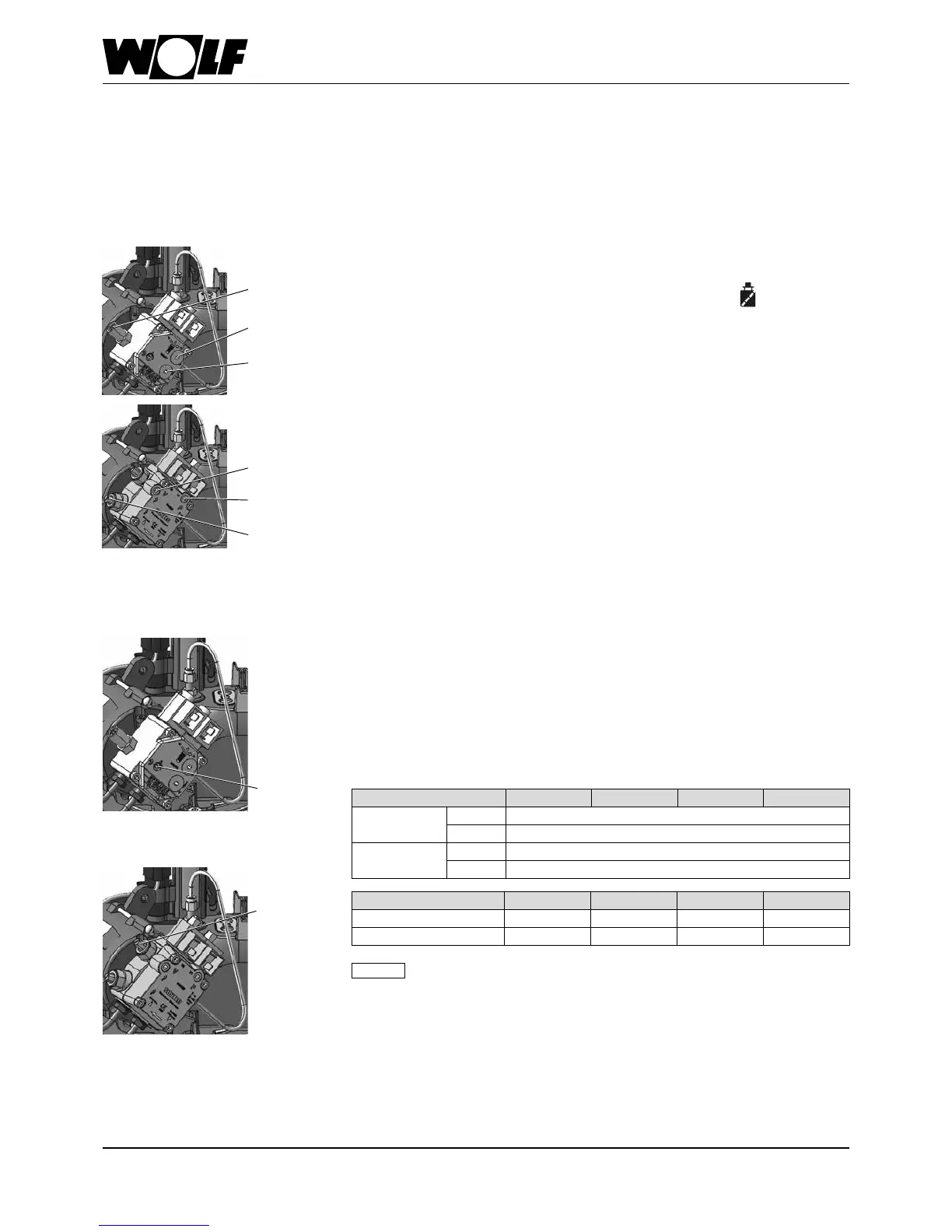

Vacuum

measurement

connection

Vacuum

measurement

connection

Oil pressure

test connection

Oil pressure

test connection

Pressure regulating

screw, stage 2

Pressure regulating

screw, stage 2

Danfoss oil pump

Suntec oil pump

AdjusttheCO

2

valueinthe

lowerload(stage1)

- Press the reset button.

- Set the heating water temperature selector to 8.

- Approx. 2 min. after the burner starts, measure the CO

2

content with the CO

2

test

equipment and compare it against the values given in the stage 1 table below.

- If required, amend the CO

2

content with the pressure regulating screw stage 1 with

a 4 mm Allen key (Danfoss design) or SW 8 open-ended spanner (Suntec design).

Take this measurement within 4 s. of the burner start. If necessary, repeat the start

phase for setting procedures by turning back the heating water temperature selector

and pressing the reset button.

Turnclockwise-higherCO

2

value

Turnanti-clockwise-lowerCO

2

value

Appliance open COB-15 COB-20 COB-29 COB-40

Set CO

2

value

Stage 2 12,7 ± 0,3%

Stage 1 12,7 ± 0,3%

O

2

set value

Stage 2 3,8 ± 0,4%

Stage 1 3,8 ± 0,4%

Appliance open COB-15 COB-20 COB-29 COB-40

Stage 2 Pump pressure 12.0 ± 2.5 bar 16.8 ± 2.5 bar 16.8 ± 2.5 bar 23.5 ± 2.5 bar

Stage 1 Pump pressure 5.0 ± 1.0 bar 8.5 ± 1.0 bar 8.5 ± 1.0 bar 11.0 ± 1.0 bar

Thepumppressureinstage2mustalwaysbegreaterthanthatinstage

1topreventdamagetotheoilpump.

- Check whether the pump pressure is still within the tolerance range. If not, then check

the oil nozzle and mixer head.

- Terminate boiler operation by turning the heating water temperature selector back to

its original position.

- Remove the oil pressure gauge and close the aperture again.

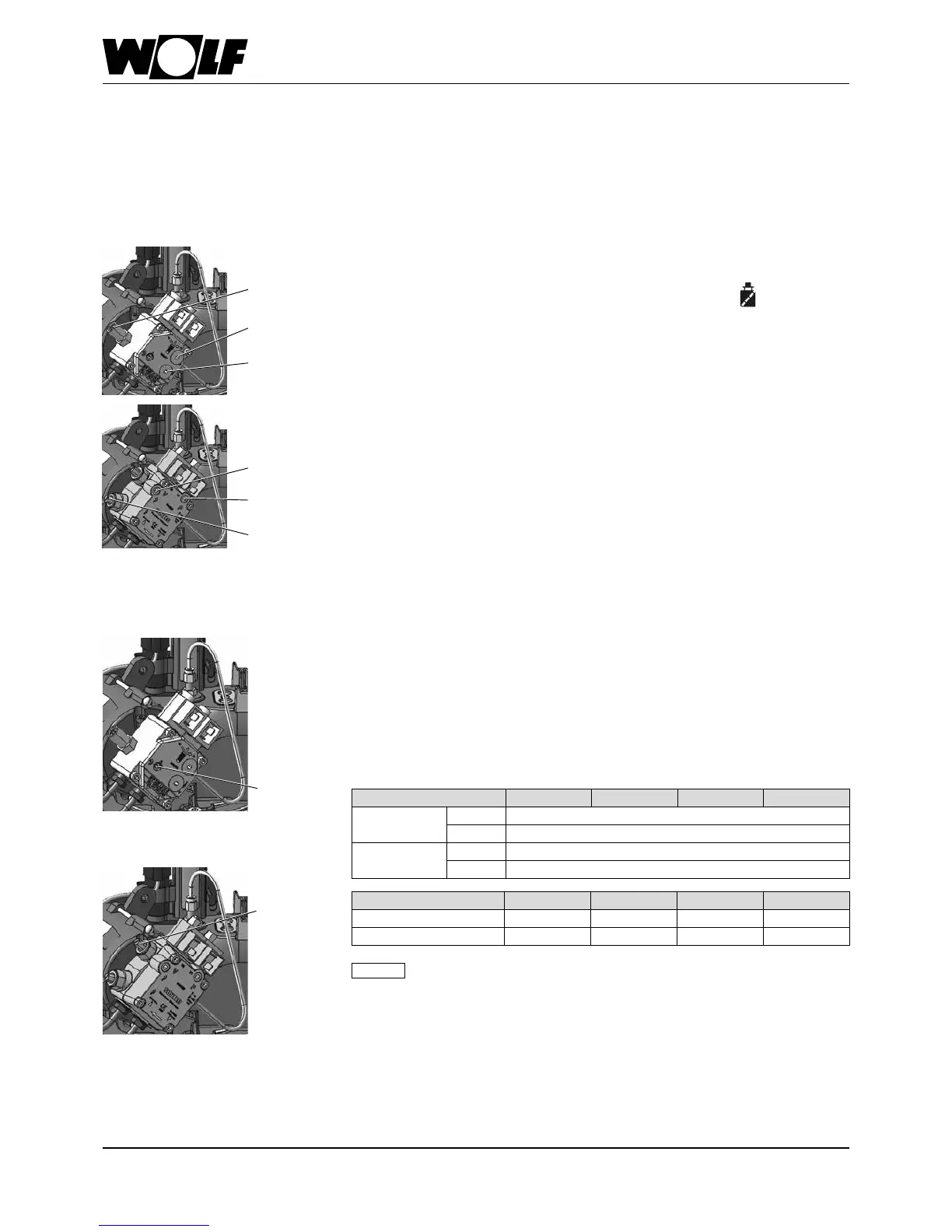

Note

Pressure

regulating

screw

Stage 1

Pressure

regulating

screw

Stage 1

Danfoss oil pump

Suntec oil pump

Loading...

Loading...