61

3062547_201802

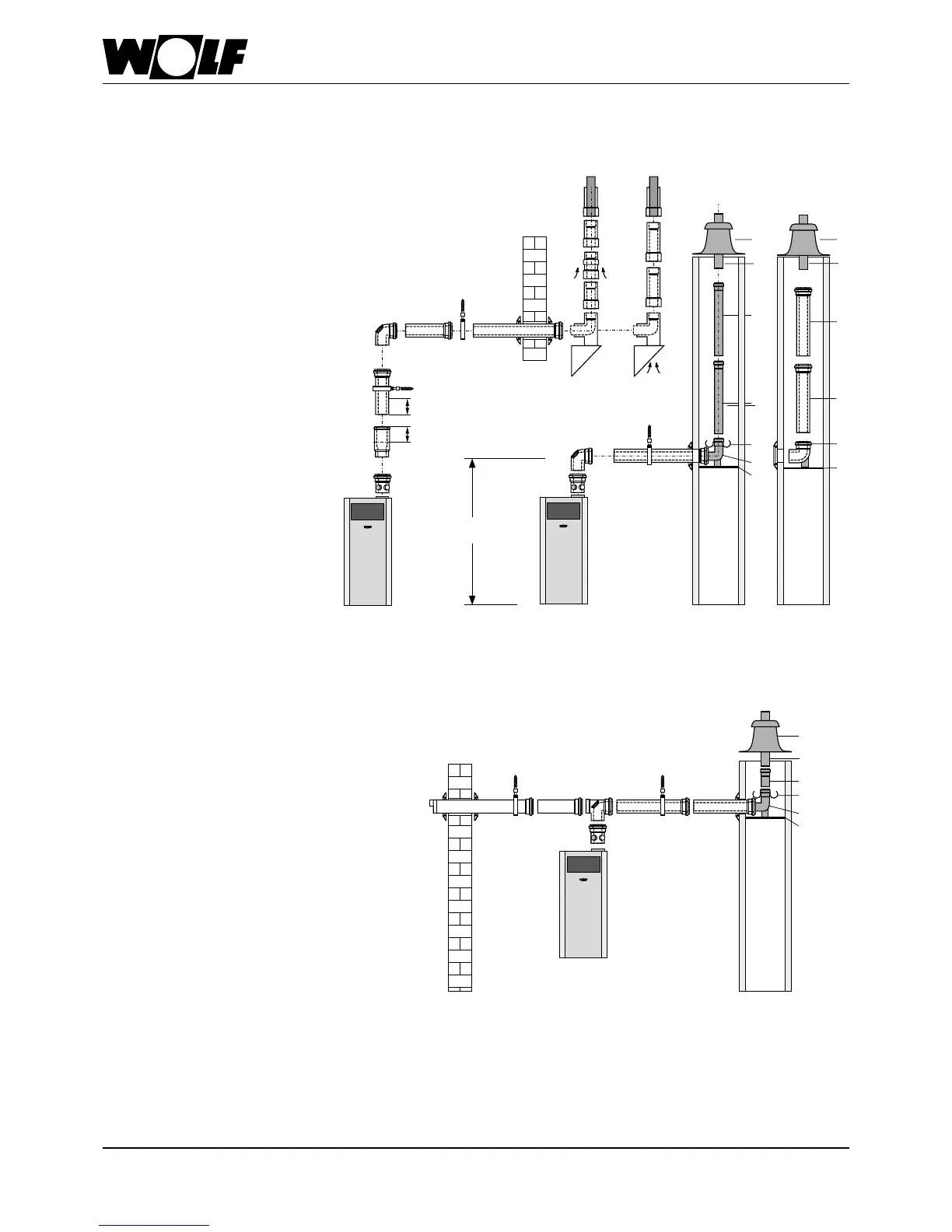

ConcentricroomsealedC33x,C93x,andueonanexternalwallC53x(examples)DN60/100,DN80/125

and DN 110/160

1 Oilcondensingboiler

2 Connectionadaptorwith

testnipple for air and ue gas

(included in COB standard

delivery)

4 Balancedue

500 mm

1000 mm

2000 mm

5 Spacerclip

7 Balancedueroutingvertical

Roof outlet for at or pitched roof

8 Separator

(sliding socket) if required

10 87°inspectionpiece

11 Bend 87°

16 Pipecollar

17 Externalwallconnection

with smooth ends on both sides of

the air pipe

18 Balancedue,externalwalls

19 Ventilationairconnector

20 Walloutlet,externalwall

21 Roofoutlet,externalwall

23 supportrail

24 87°supportbend

25 Spacer

26 PPuepipe

500 mm

1000 mm

2000 mm

27 Shaftcover

28 Airpipe

29 Airintakepipe

33 PP outlet

Install the horizontal ue with a fall of approx. 3° (6 cm/m) towards the boiler. Route the

horizontal air supply with a 3° fall towards the outside – install the air inlet with wind

protection; permissible wind pressure at the air inlet 90 Pa. The burner will not operate

with higher wind pressure. In a duct, after the support bend (24), a rigid or exible ue

can be connected.

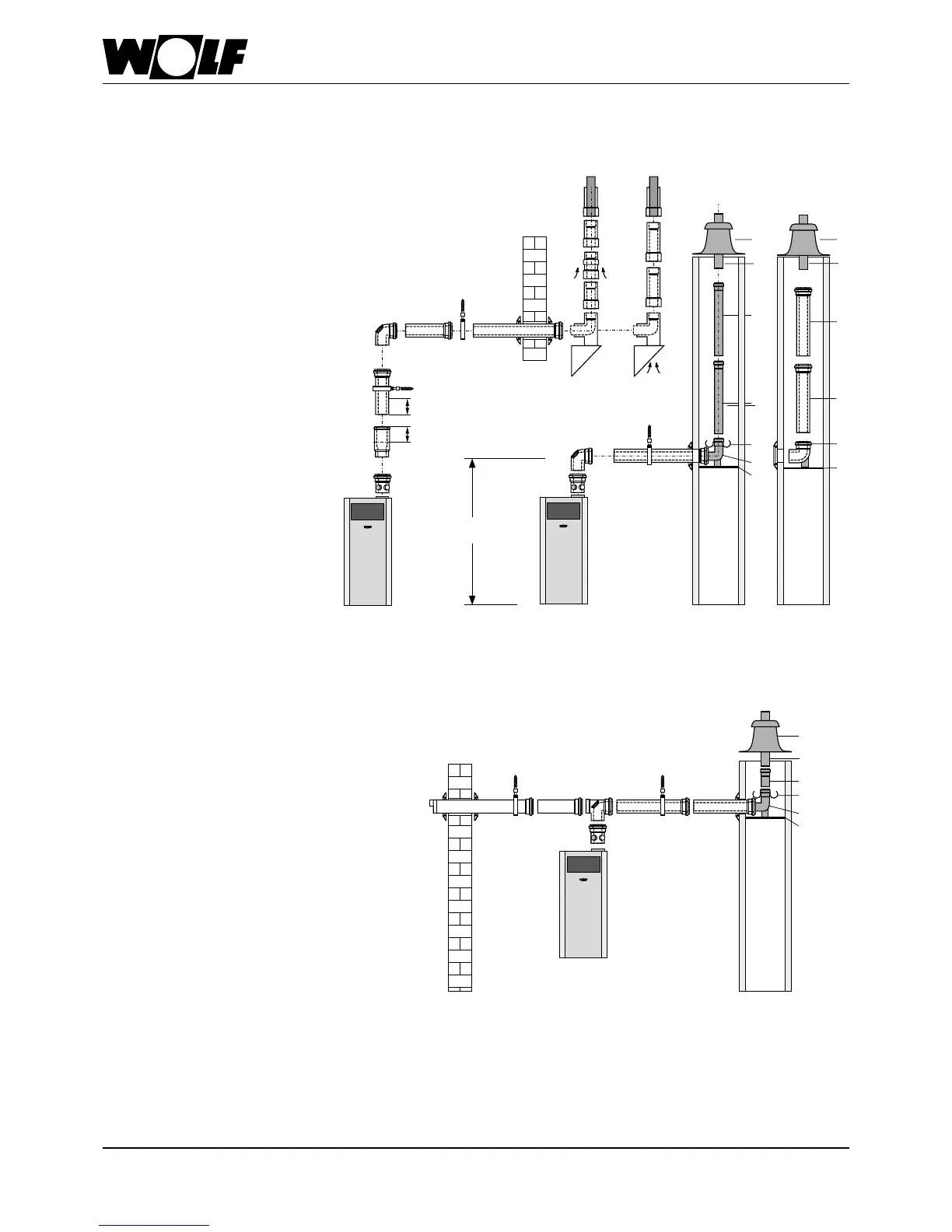

C53x

C33x, C93x

26

17

18

C53 x

36 Technicalinformation

approx. 1500 mm (COB-15/20/29)

approx. 1700 mm (COB-40)

Flue routed along external wall

Loading...

Loading...