ENGINE

5-66

BY Service Manual

Cylinder Block and Crankshaft

Inspection of Cylinder Block

1. Remove all main bearing inserts. Ensure the

bearing seating surfaces are free of any debris.

2. Ensure that oil passages are clear and

unobstructed.

3. Check for discoloration or evidence of cracks. If

a fracture is suspected, use the color check

method or the MAGNAFLUX method to

determine if the cylinder block is fractured.

Figure 5-111

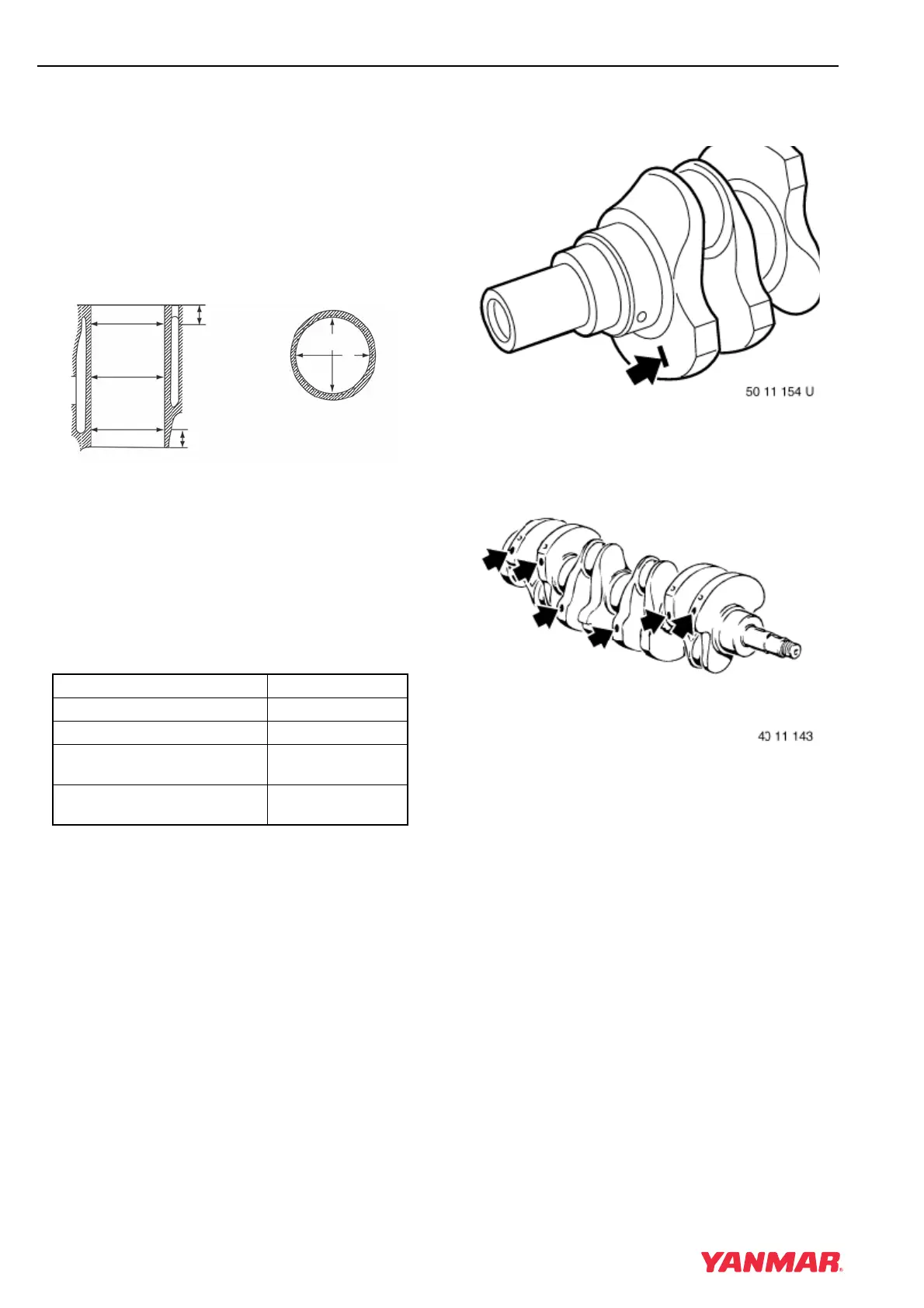

4. Measure cylinders for roundness, taper and

inspect for evidence of scoring. Consider

honing or replacing the cylinder block if the

measurements are not within specification.

5. Take measurements at three places (a, b, c),

and in two directions (d and e) in each cylinder.

Cylinder Bore Specifications

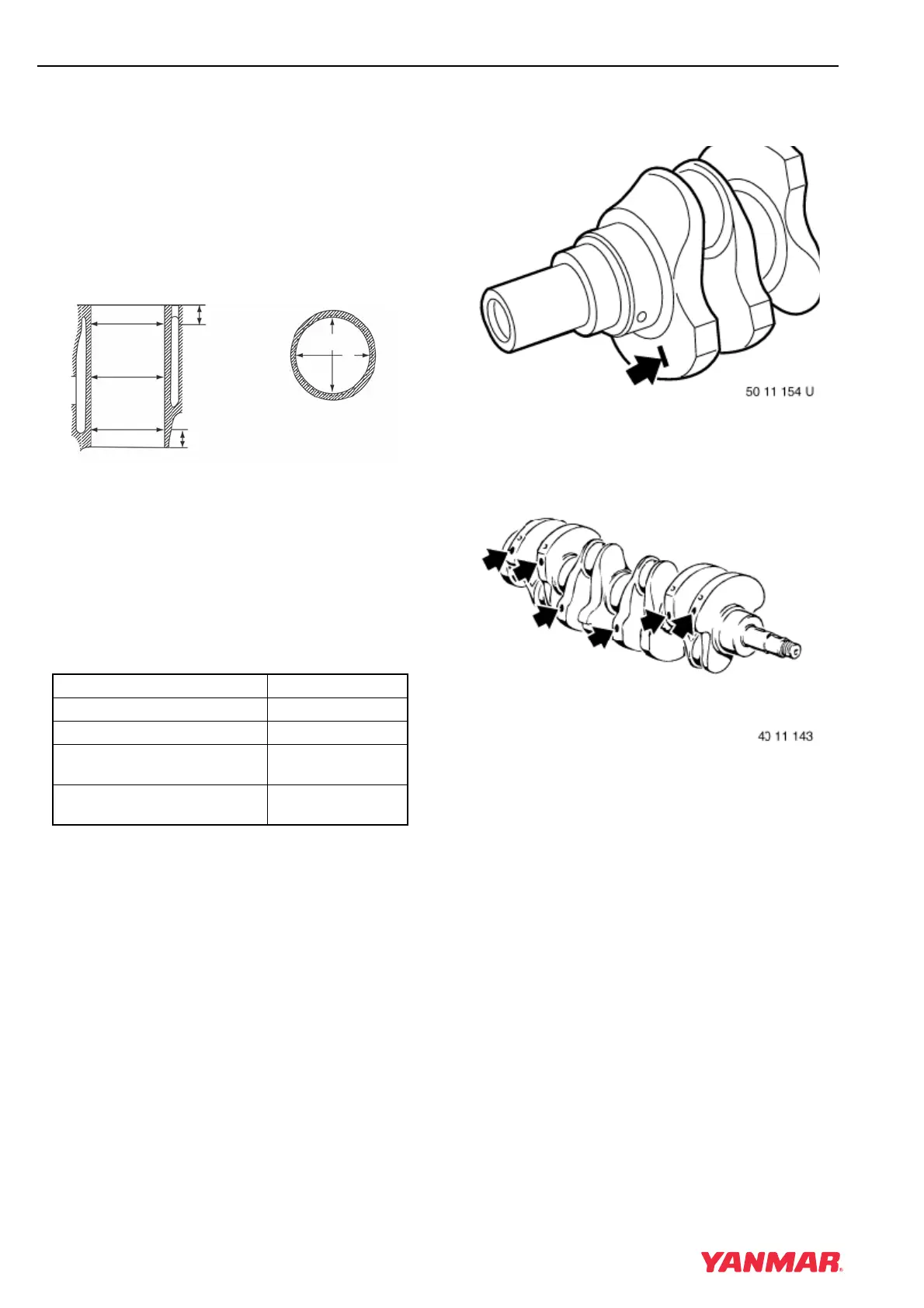

Crankshaft Installation

1. Select the correct bearing as follows:

Figure 5-112

(a) Locate and record the grinding size of

crankshaft (Figure 5-112).

Figure 5-113

(b) The crankshaft will be marked with yellow,

green or white paint to determine the correct

bearing shell to install in the bearing caps

(Figure 5-113).

Inspection Item*

*Values are for new or reconditioned cylinders.

Specification

Bore Diameter stage 0 84.007 ±0.007 mm

Bore Diameter stage 1 84.257 ±0.007 mm

Permitted out of round of cylinder

bore

0.005 mm

Permitted conicity of cylinder

bore

0.01 mm

0000230B

a

b

c

d

e

20 mm

(0.75 in.)

20 mm

(0.75 in.)

Loading...

Loading...