ENGINE

5-38

BY Service Manual

Pistons and Cylinders

2. Clean piston ring grooves using a piston ring

groove cleaning tool. Follow tool manufacturer’s

instructions for correct operation.

3. Wash pistons in an appropriate solvent using a

soft-bristled brush.

4. Visually inspect each piston for cracks. Pay

particular attention to the ring lands between

the piston ring grooves.

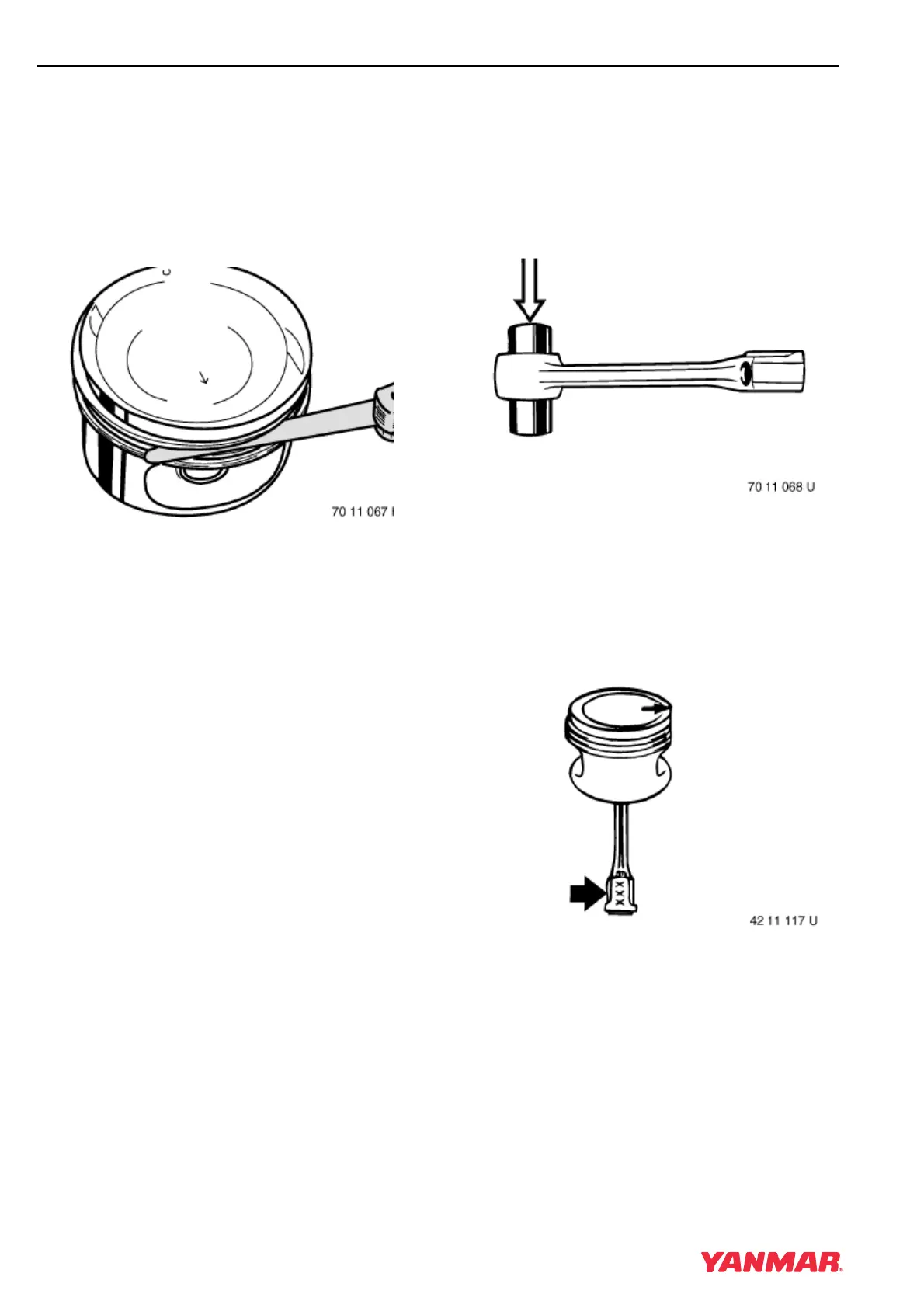

Figure 5-50

5. Install a new piston ring. See Assembling

Piston and Connecting Rod on page 5-38. Use

a feeler gauge to measure the gap between the

ring and the piston (Figure 5-50). Replace the

piston if not within specification. Repeat with

the second ring.

Note: The oil ring (third groove) cannot be

measured.

6. Repeat steps for each of the cylinders and the

piston rings for that specific cylinder.

Assembling Piston and Connecting

Rod

1. Clean the piston and rings thoroughly without

damaging the ring grooves.

2. Oil the wrist pin bore and wrist pin before

assembling.

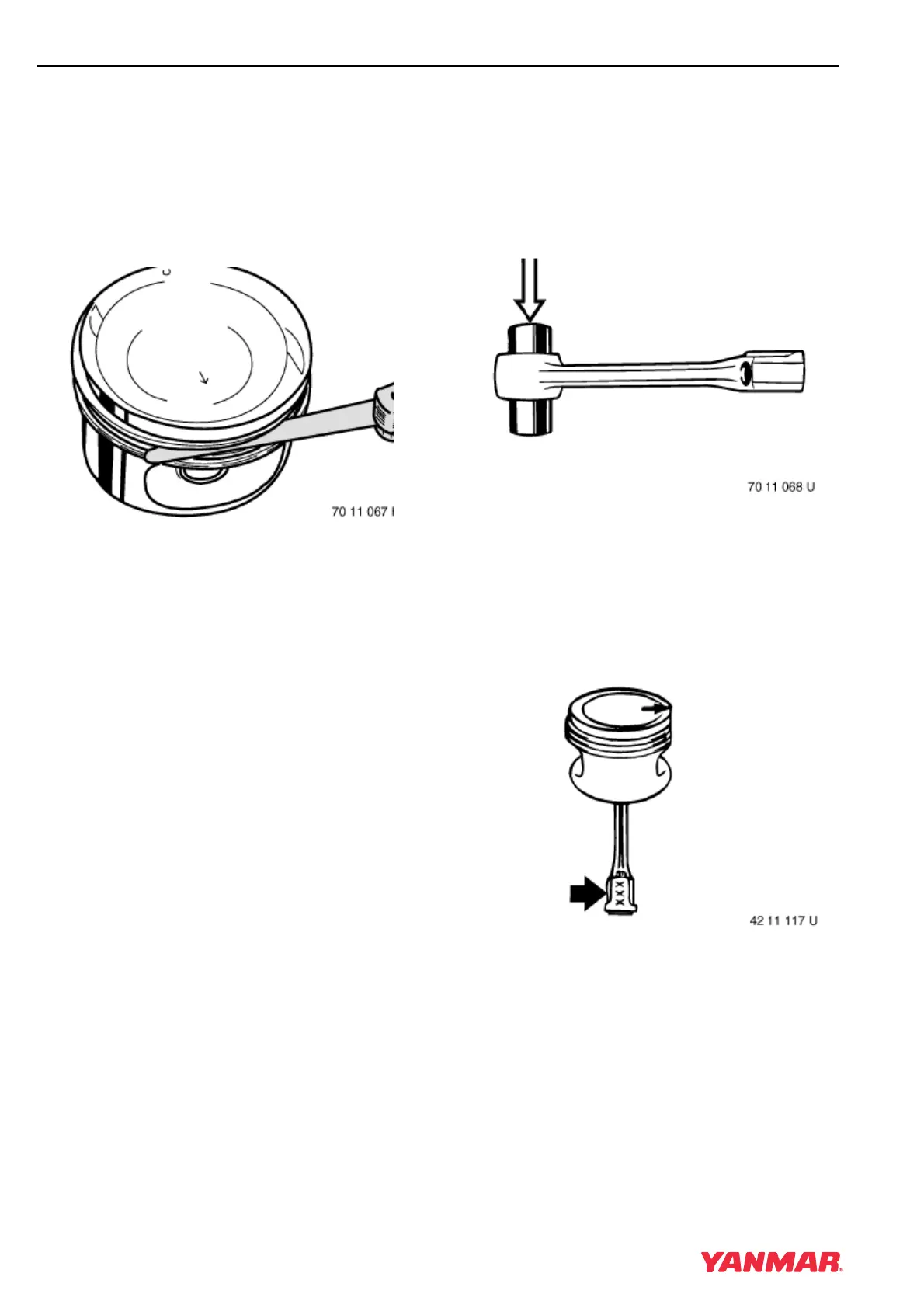

Figure 5-51

3. Check the fit of the wrist pin in the connecting

rod. The wrist pin should pass through the

bushing with little force and not have any

significant play (Figure 5-51).

4. Install one retaining ring in the piston with the

gap in the retaining ring opposite the recess.

Figure 5-52

5. Orient the piston and connecting rod as shown

for assembly (Figure 5-52). The arrow on top of

the piston must point to the right when the

connecting rod identification marks are visible.

Loading...

Loading...