FUEL SYSTEM

BY Service Manual

6-11

Tests and Adjustments

TESTS AND ADJUSTMENTS

IMPORTANT

After completing work that involves opening

the fuel system do the following:

Bleed the system. See Bleeding the Fuel

System on page 6-29.

Start engine and check for leaks. Allow

engine to run until it is running smoothly.

Check and delete any trouble codes that are

registered in the ECU after the work has

been completed.

Measuring Fuel Feed Pump Pressure

Procedure

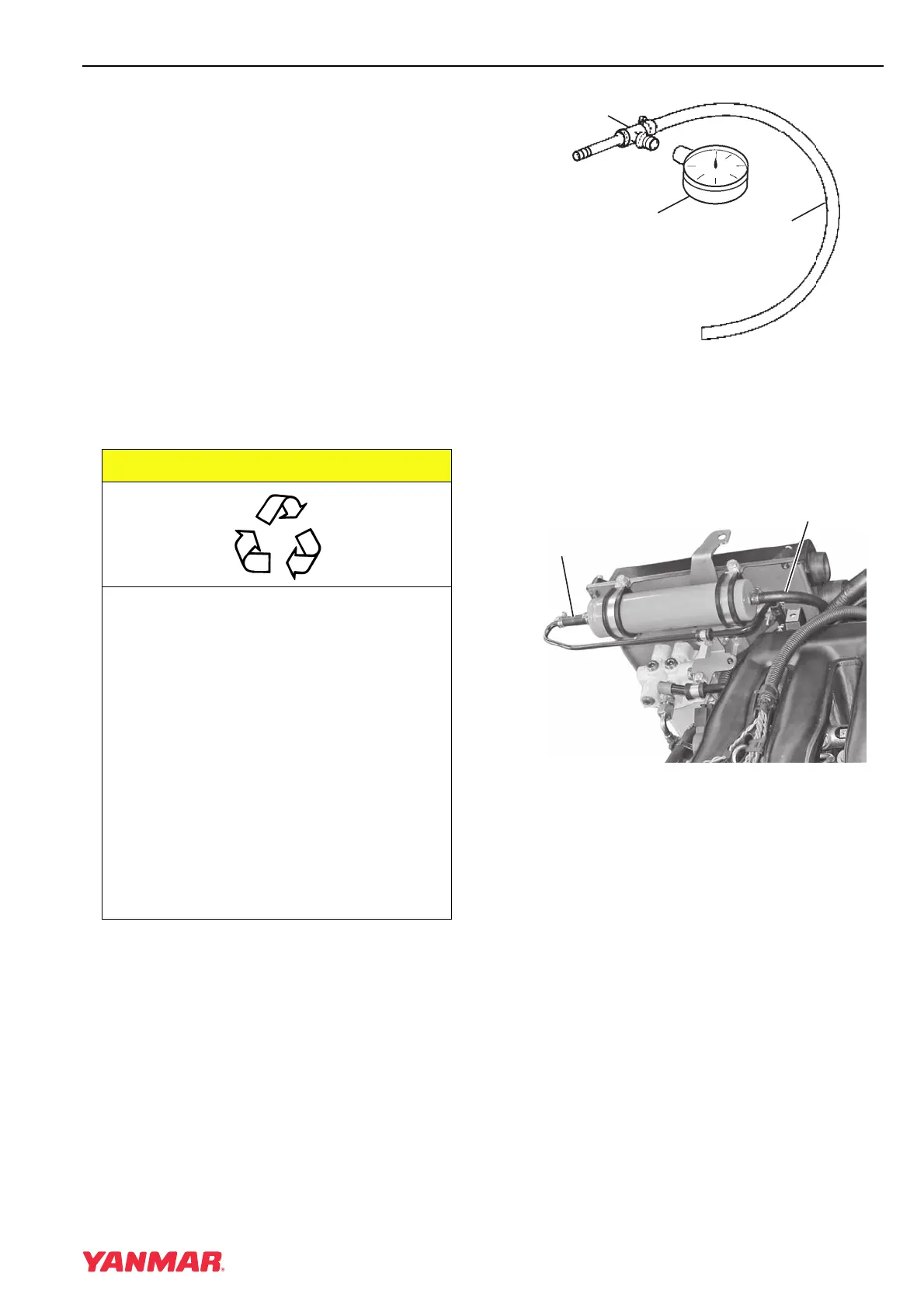

Figure 6-4

1. Assemble a suitable fuel pressure gauge to a

tee, and connect a short length of hose to one

of the remaining two legs of the tee

(Figure 6-4, (1)).

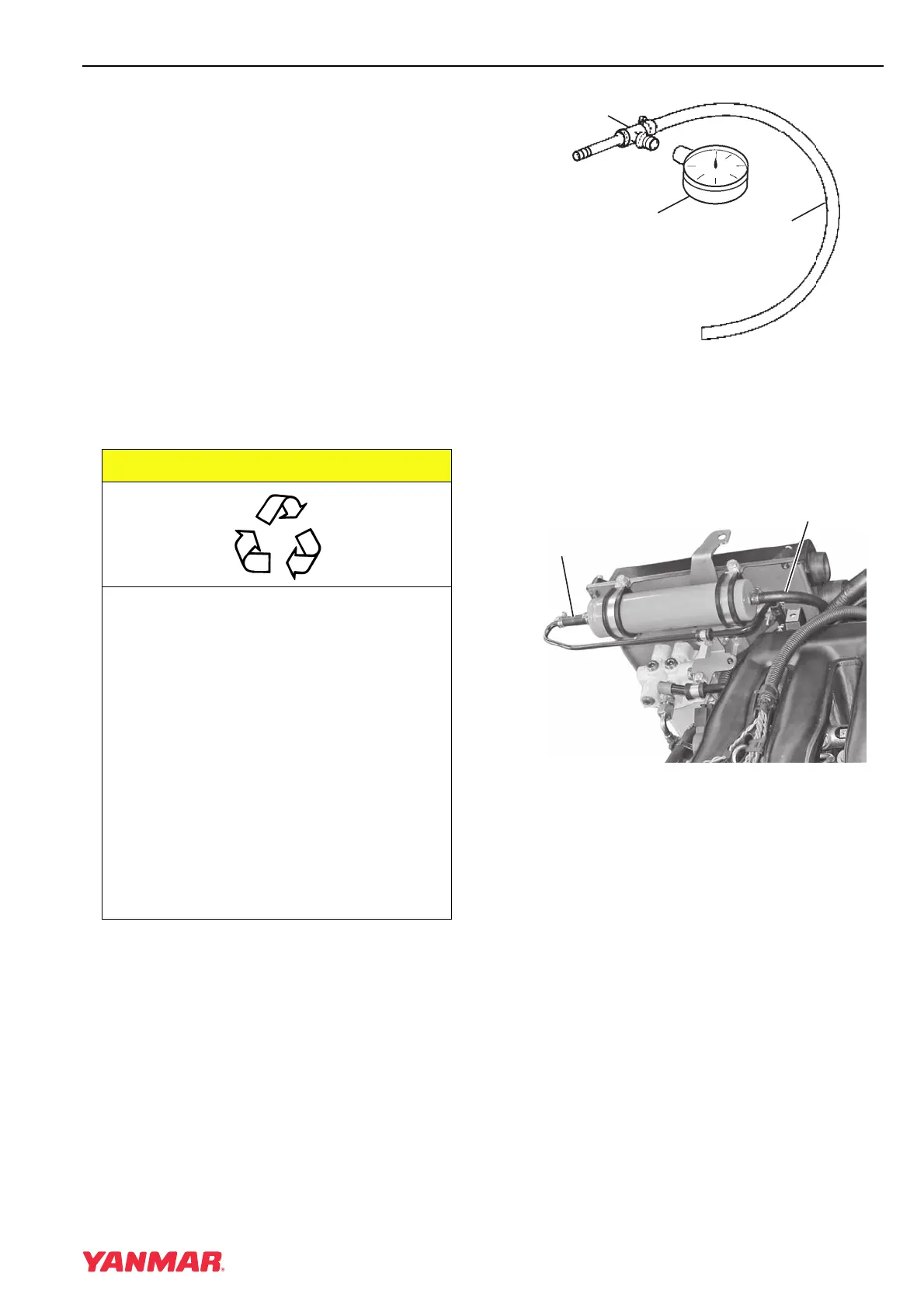

Figure 6-5

2. Disconnect the fuel hose from the fuel fine filter

inlet (Figure 6-5, (1)).

3. Connect test gauge assembly between

disconnected ends. Install and tighten hose

clamps.

4. Start engine and set speed to low idle. Read

and record pressure.

5. Operate engine at full load. Read and record

pressure.

CAUTION

• ALWAYS be environmentally

responsible.

• Follow the guidelines of the EPA or

other governmental agencies for the

proper disposal of hazardous

materials such as engine oil, diesel

fuel and engine coolant. Consult the

local authorities or reclamation facility.

• NEVER dispose of hazardous

materials irresponsibly by dumping

them into a sewer, on the ground, or

into ground water or waterways.

• Failure to follow these procedures may

seriously harm the environment.

0000013en

0003682

(3)

(1)

(2)

0003676

(2)

(1)

Loading...

Loading...