ENGINE

BY Service Manual

5-37

Pistons and Cylinders

IMPORTANT

Do not allow the connecting rod to bump the

crankshaft journal during piston removal.

Damage to the bearing journal may result.

10. Push the piston and connecting rod out of the

cylinder. Use a wooden dowel against the

connecting rod if necessary.

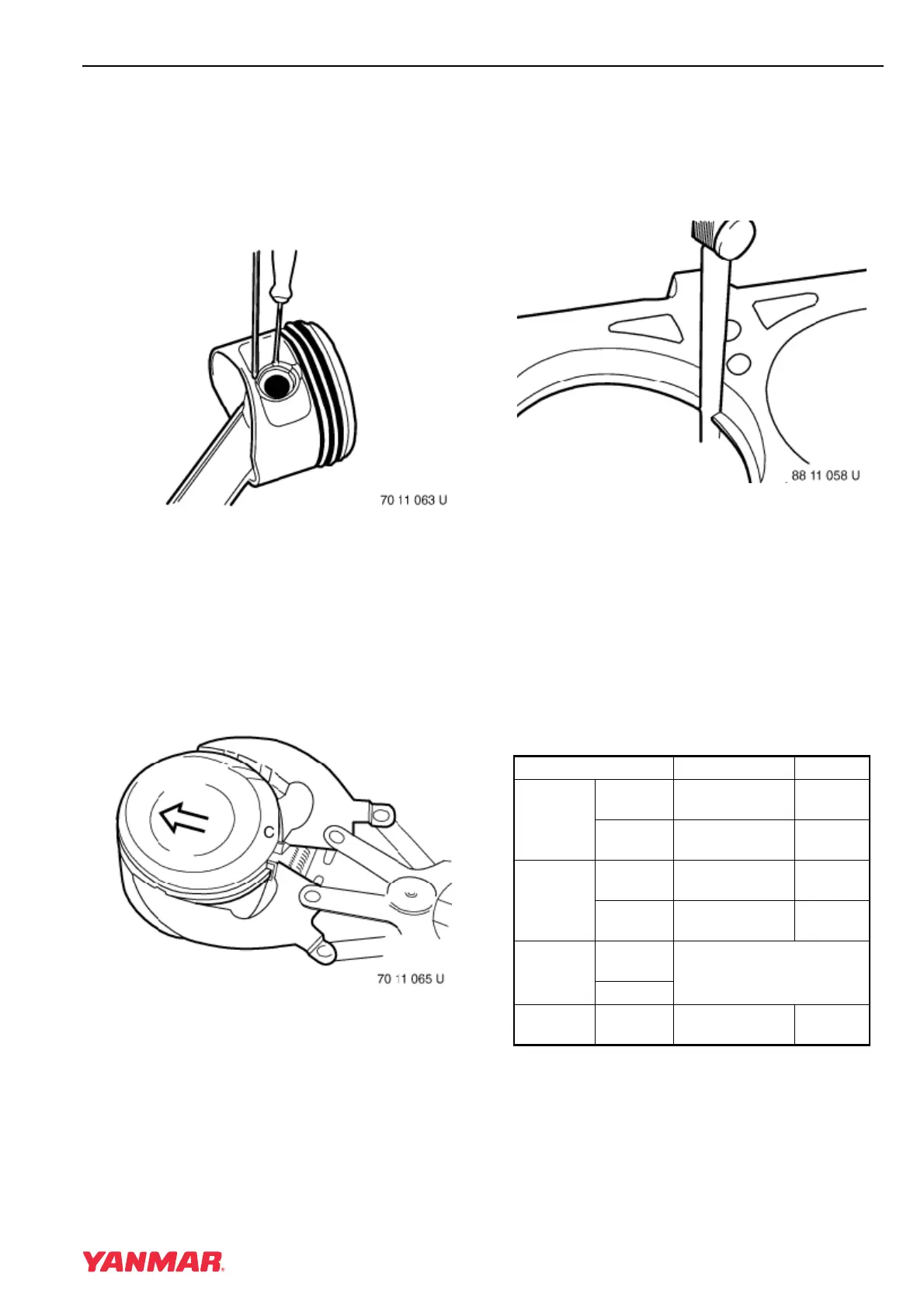

Figure 5-47

11. Remove the wrist pin retaining rings

(Figure 5-47).

IMPORTANT

Pistons and wrist pins are matched. NEVER

mix parts.

12. Push out the wrist pin. Keep piston and

matched wrist pin together.

Figure 5-48

13. Use a piston ring expander (Figure 5-48, (1)) to

remove the piston rings, taking care not to

scratch the surface of the piston.

Inspection of Pistons and Piston

Rings

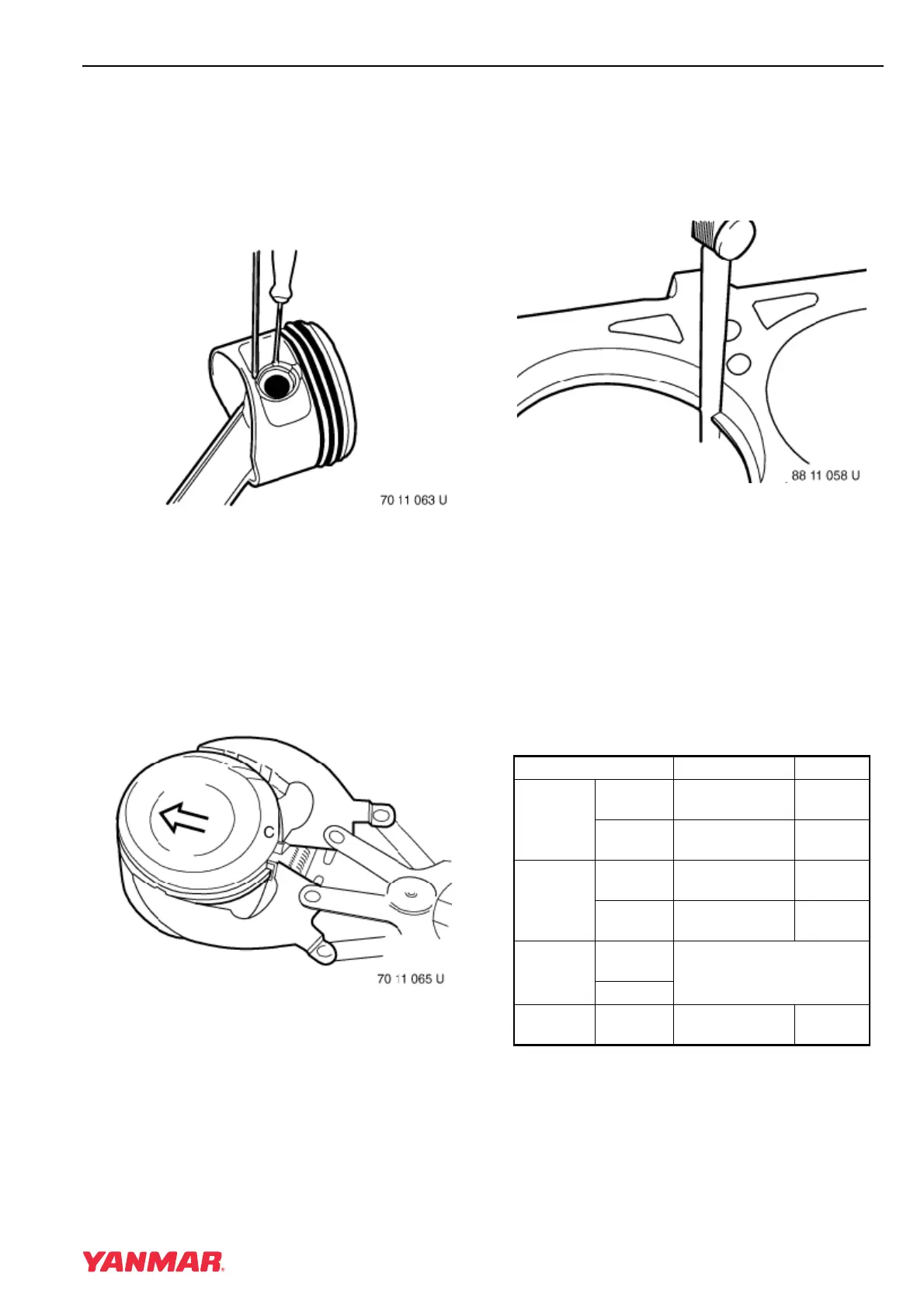

Figure 5-49

Note: Measure cylinder bore to ensure it is

within specifications before measuring

piston ring end gap. See Inspection of

Cylinder Block on page 5-66.

1. Insert each piston ring, one at a time, into the

cylinder. Use a piston with the piston rings

removed to slide the ring squarely into the

cylinder bore. Measure the end gap of each

piston ring (Figure 5-49).

Specifications

Inspection Item Standard Limit

Top Piston

Ring

Side

Clearance

0.12 - 0.16 mm

(0.005 - 0.006 in.)

-

End Gap

0.20 - 0.35 mm

(0.008 - 0.014 in.)

-

Second

Piston

Ring

Side

Clearance

0.07 - 0.11 mm

(0.003 - 0.004 in.)

-

End Gap

0.30 - 0.45 mm

(0.012 - 0.018 in.)

-

Oil Ring

Side

Clearance

Cannot be measured

End Gap

Piston-to-

Cylinder

Clearance

0.15 mm

(0.006 in.)

Loading...

Loading...