5-58

Continued

—For undertorque detection during accel or decel, set to " 3 " or " 4 ".

—For continuous operation after undertorque detection, set to " 1 " or " 3 ". During detection, the Digital Operator

displays and “ UL3 ” alarm (blinking).

—To stop the drive at an undertorque detection fault, set to " 2 " or " 4 ". At detection, the Digital Operator displays an

" UL3 " fault.

—To output an undertorque detection signal, set output terminal function selection (n057, n058 or n059 ) to

" 8 " or " 9 ".

B. n118 : Undertorque Detection Level

Factory setting: 10 %

Range: 0 to 200 %

This is the reference point for determining that an undertorque condition exists. Set as a percent of Drive rated

current or as a percent of motor rated torque.

C. n119 : Undertorque Detection Time

Factory setting: 0.1 sec.

Range: 0.1 to 10.0 seconds

Determines how long an undertorque condition must exist before another event will occur, e.g. coast to stop,

multi-function output change of state, or UL3 warning or fault display.

D. n057 : Multi-function Output 1 Data 6 or 7 :Overtorque

(terminals MA, MB & MC) Detection

n058 : Multi-function Output 2 Data 8 or 9 : Undertorque

(terminals P1 & PC) Detection

n059 : Multi-function Output 3

(terminals P2 & PC)

A Form-C contact, or an open collector output, can be programmed to change states during an

overtorque/undertorque detection condition.

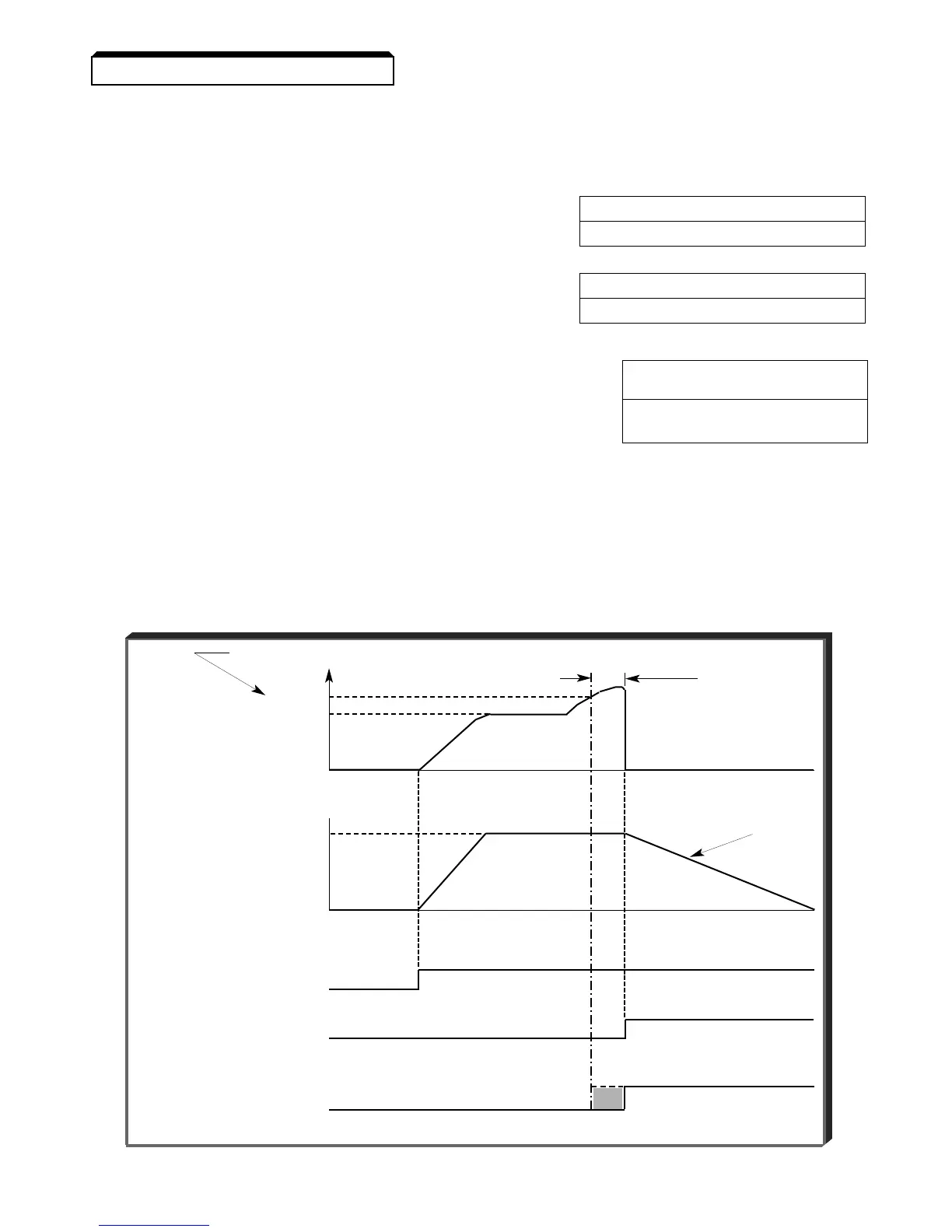

EXAMPLE OF OVERTORQUE DETECTION

n096 setting: 2 — Overtorque enabled, only at set frequency, coast to stop

n057 setting: 6 — Output contact programmed for overtorque detection

n096 setting: 110 %— Level at which overtorque is sensed

n099 setting: 1.0 s— Time delay before overtorque event occurs

Detection level

(n098 )

Detection

110% time

OUTPUT 100% (n099)

CURRENT/

TORQUE

0

100%

Coast

MOTOR

stop

SPEED

0

RUN

SIGNAL

FAULT

SIGNAL

CONTACT OUTPUT

(OVERTORQUE

DETECTION)

TERM. MA & MC)

Overtorque Detection Timing Diagram

5.34 UNDERTORQUE DETECTION

Loading...

Loading...