1-6

The Drive leaves the factory with all parameters set for 2-Wire external reference control. Figure 1-5

must be used for all external connections.

To use the Drive in a 3-Wire application, drive parameters n001, n003, and n004 must be

reprogrammed, using the Digital Operator. Figure 1-6 must then be used for all external connections.

IMPORTANT

When a cable gland is used for water and dust tight type (NEMA type 4X/12) models, observe the

following:

• Use multi-core cable for cable gland. (If more than one cable is inserted into one cable gland,

a gap is created and may cause leakage.)

• Seal the cable gland with a gasket without fail. (A gasket is attached to the recommended

cable gland.)

A. Main Circuit Input /Output Wiring

Complete wire interconnections according to Table 1-2, Figure 1-5 thru Figure 1-7. Be sure to

observe the following:

• Use 600V vinyl-sheathed wire or equivalent. Wire size and type should be determined by local

electrical codes.

•Avoid routing power wiring near equipment sensitive to electrical noise.

•Avoid running input and output wiring in the same conduit.

• NEVER connect AC main power to output terminals T1(U), T2(V), and T3(W).

• NEVER allow wire leads to contact metal surfaces. Short-circuit may result.

• NEVER connect power factor correction capacitors to the drive output. Consult Yaskawa when

connecting noise filters to the drive output.

• WIRE SIZING MUST BE SUITABLE FOR CLASS I CIRCUITS.

•When connecting motor to drive’s output terminals, include a separate ground wire. Attach

ground wire solidly to motor frame and to drive’s ground terminal .

•When using armored or shielded cable for connection between drive and motor, solidly connect

armor or shield to motor frame, and to drive’s ground terminal .

• Motor lead length should NOT EXCEED 164 feet (50 meters), and motor wiring should be run in

a separate conduit from the power wiring. If lead length must exceed this distance, reduce carrier

frequency (see paragraph 5.8) and consult factory for proper installation procedures.

• Use UL listed closed loop connectors or CSA certified ring connectors sized for the selected wire

gauge. Install connectors using the correct crimp tool recommended by the connector manufacturer.

1.4 ELECTRICAL INSTALLATION

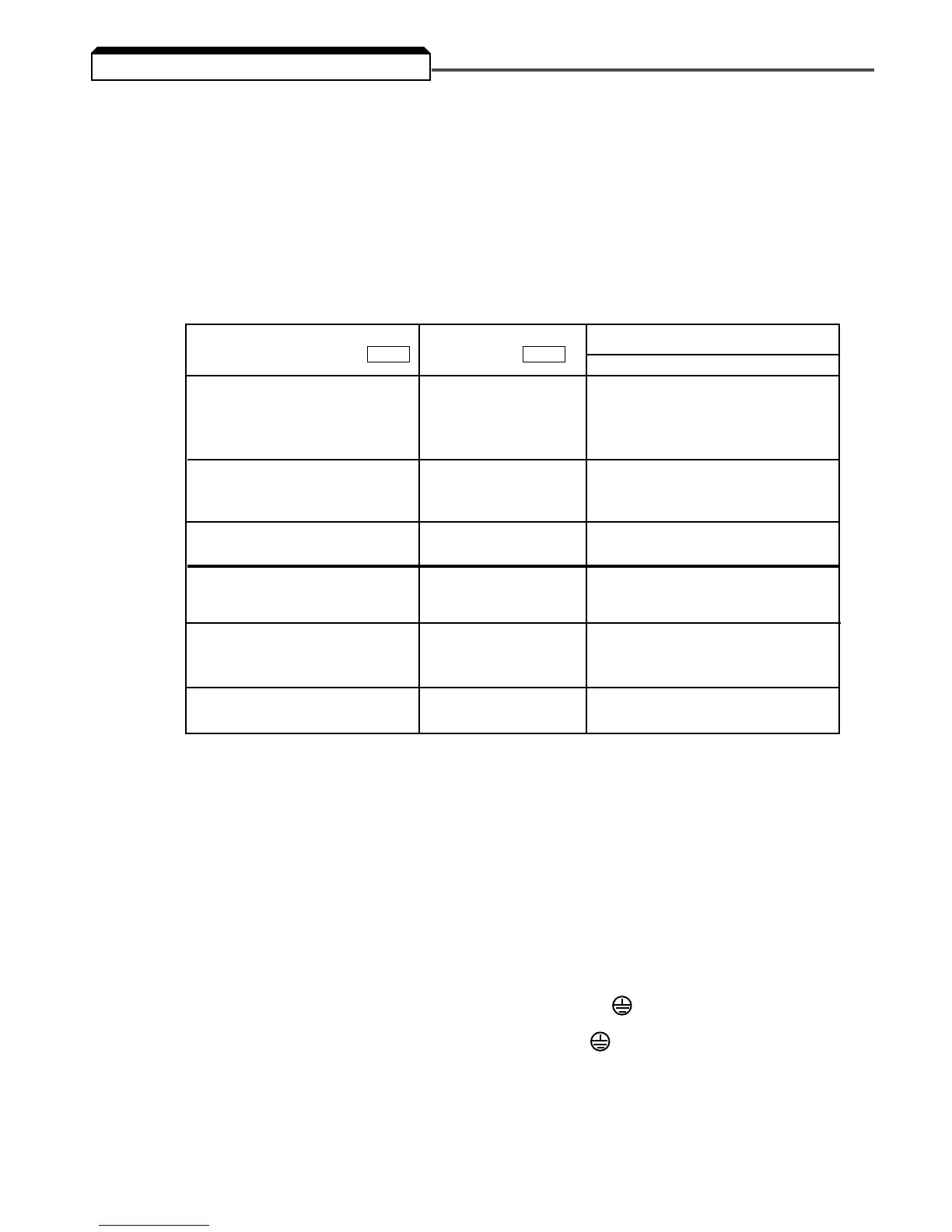

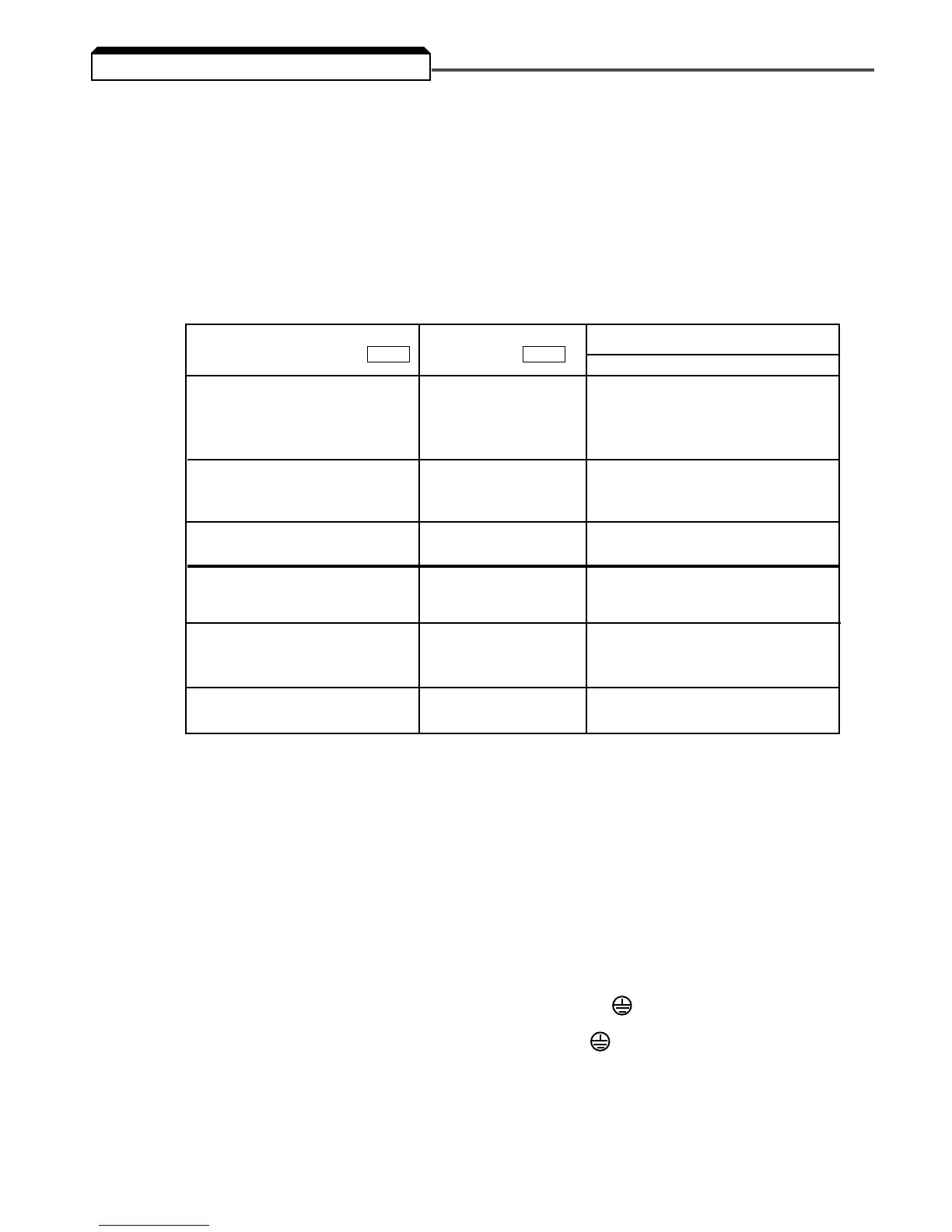

Model CIMR-V7* MV

Dimensions in inches (mm)

Qty-Dia

20P1 A001

20P2 A002 3-0.89 DIA

20P4 A003 (3-Ø 22.6)

20P7 A005

21P5 A008

22P2 A011

23P7 A017

25P5 A025 3-1.38 DIA

27P5 A033 (3-Ø 35)

40P2 B001

40P4 B002

40P7 B003

41P5 B005

42P2 –

43P7 B009

45P5 B015 3-1.38 DIA

47P5

–

(3-Ø 35)

Cable Gland Mounting Hole

3-1.06 DIA

(3-Ø 26.8)

3-0.89 DIA

(3-Ø 22.6)

3-1.06 DIA

(3-Ø 26.8)

Loading...

Loading...