JOHNSON CONTROLS

201

SECTION 7 - OPERATION

FORM 201.23-NM2

ISSUE DATE: 09/25/2020

7

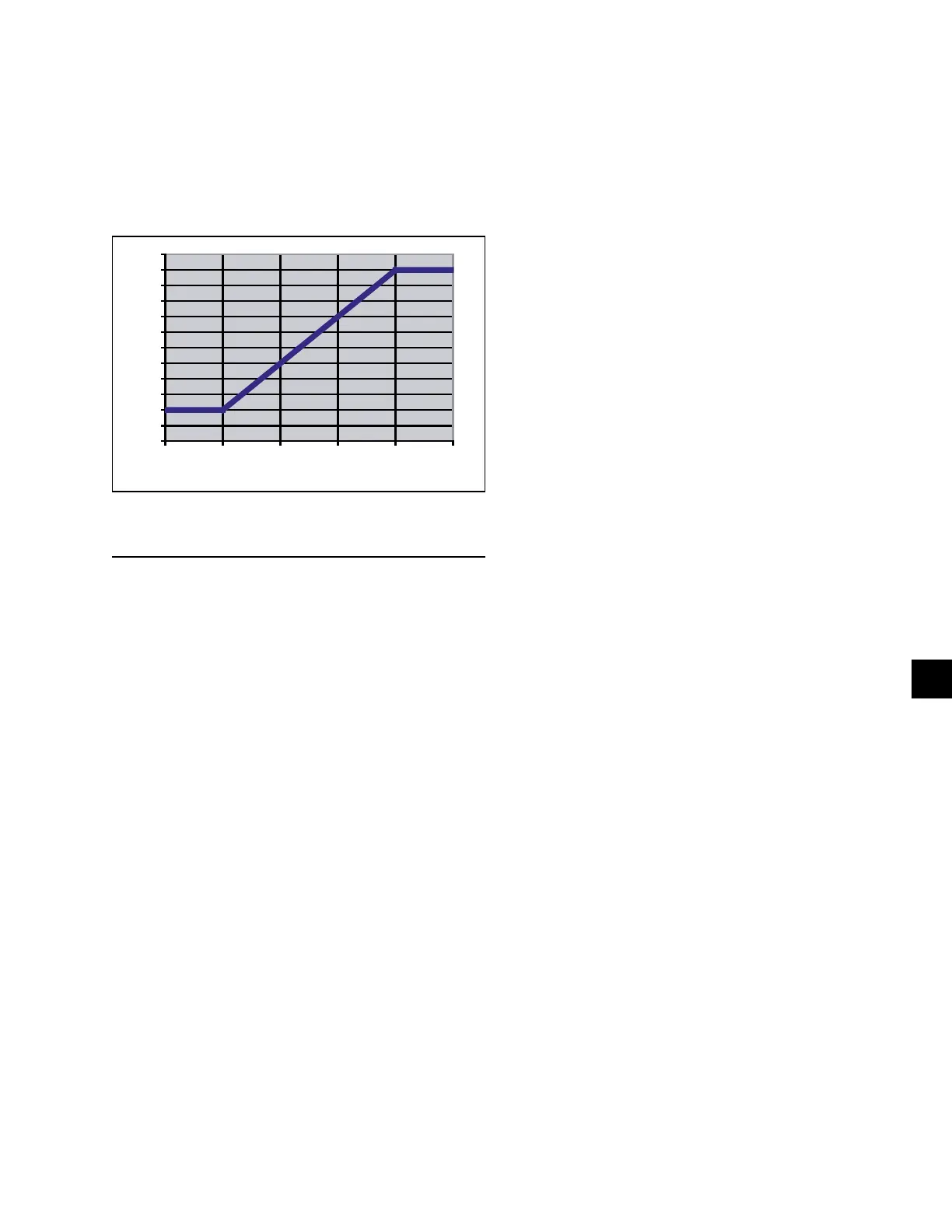

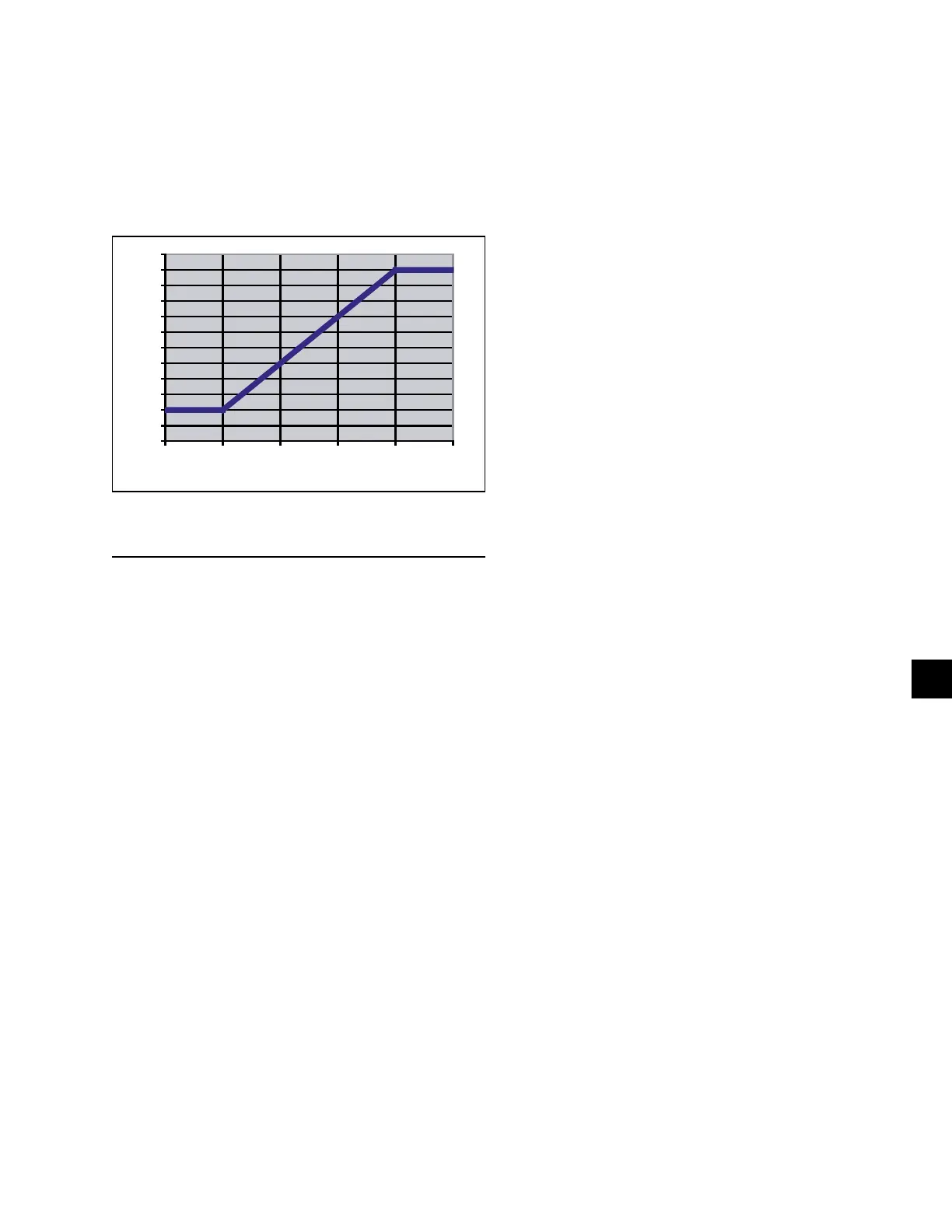

• If the ambient is between 110 and 125°F (43 and

52°C), the Minimum VSD Run Frequency is

scaled according to the following formula:

(3 x Ambient Temperature) - 280°F.

The formula is also represented by the graph in Figure

52 on page 201.

NOTE: The graph above also illustrates the scaled frequency:

FIGURE 52 - MINIMUM VSD RUN FREQUENCY

LD10628

40

45

50

55

60

65

70

75

80

85

90

95

100

105 110 115 120 125 130

Ambient Temperature (°F)

Mini mum VSD Frequency (Hz)

• If the ambient temperature is more than 125°F, the

Minimum VSD Run Frequency will be 95 Hz.

ACCELERATION / DECELERATION

RATE WHEN STARTING / STOPPING

COMPRESSORS

VSD Acceleration and Deceleration Rates

The acceleration rate changes with frequency and fol-

lows the guidelines below:

• Between 0 Hz and 50 Hz, the acceleration is 10

Hz/s.

• Between 50 Hz and 200 Hz, the acceleration is

30.4 Hz/s. Even though the acceleration rate of

30.4 Hz/s is possible up to 200 Hz, the frequency

(speed) is limited by the minimum start frequency

and the add a compressor frequency calculation

performed by the microprocessor when bringing

on an additional compressor.

When decelerating, the deceleration rate changes with

frequency and follows the guidelines below:

• Between 200 Hz and 100 Hz, the deceleration

time is 30.4 Hz/s.

• Between 100 Hz and 0 Hz, the deceleration time

is 10 Hz/s.

When a compressor stops, back-spin of the compres-

sor will often occur as the pressure differential between

discharge and suction equalizes. This should not be a

cause of concern.

STANDARD IPLV CAPACITY CONTROL

(Loading/Unloading and starting additional compressors)

Standard IPLV Capacity Control is installed in the

chiller at the factory using a dedicated EPROM (soft-

ware), part # 031-02476-001, for “Standard Only”

IPLV control. If the LCHLT is more than the pro-

grammed Setpoint plus CR, only a single compressor

is permitted to start under Standard IPLV control. The

compressor will start at the minimum start frequency

based on ambient temperature (Page 214). The lead

compressor Feed and Drain Valves will immediately

begin to control superheat and liquid level in the flash

tank.

When a compressor starts, the load and unload timers

will be set to 30 seconds. During the first 30 seconds

of operation after a compressor reaches the start fre-

quency, loading/unloading is inhibited.

After 30 seconds, the control logic looks at the LCHLT

temp, compares it to the Setpoint plus CR, and makes

decisions to load or unload.

For precise capacity control, the Chiller Control Board

microprocessor loads and unloads compressors quick-

ly, as fast as every 2 seconds, in increments of 0.1 to

1 Hz each time a load or unload change is required.

Fixed load and unload timers of 2 sec. are set, after a

speed change of 0.11 to 1 Hz, to minimize undershoot

and overshoot.

As additional cooling is required (LCHLT more than

Setpoint plus CR), the Chiller Control Board micro-

processor will increase the speed of the compressor at

the rate of 0.1 Hz to 1 Hz every 2 seconds until the load

is satisfied. Loading will continue to occur as long as

leaving chilled liquid temperature is above the Setpoint

plus CR.

If the temperature falls very near or within the Control

Range, the Chiller Control Board microprocessor will

make decisions regarding speed changes under condi-

tions where the “error” and “rate” conflict. Under these

conditions, loading/unloading follows the guidelines

described in the Fuzzy Logic Control on page 205.

Loading...

Loading...