JOHNSON CONTROLS

235

SECTION 8 - MICROPANEL

FORM 201.23-NM2

ISSUE DATE: 09/25/2020

8

SYSTEM SAFETIES (FAULTS)

System Safety (Fault) Operation

System safeties are faults that cause individual systems

to be shut down if a safety threshold is exceeded for 3

seconds. System faults are auto reset faults in that the

system will be allowed to restart automatically after the

120 second anti-recycle timer times out. The only ex-

ception is after any 3 faults on the same system occur

within 90 minutes, that system will be “locked out” on

the last fault. The lockout condition requires a manual

reset using the system switch. The respective system

switch must be cycled off and on to clear the lockout

fault. See Table 21 on page 262 for the programmable

limits for many of the cutouts.

When multiple systems are operating and a system

fault occurs, the running systems will ramp down and

the faulted system will be shut off and the previously

operating will restart if required after the fault clears

and/or the 120 second anti-recycle timer times out.

In the descriptions of the fault displays that follow, the

fault message will show a YYYYYYYY to indicate

that a system is in a “FAULT” condition and will re-

start when the fault clears, or “LOCKOUT” and will

not restart until the operator clears the fault using the

keypad. If a system safety is in effect, the message will

be displayed to the operator when the STATUS key is

pressed.

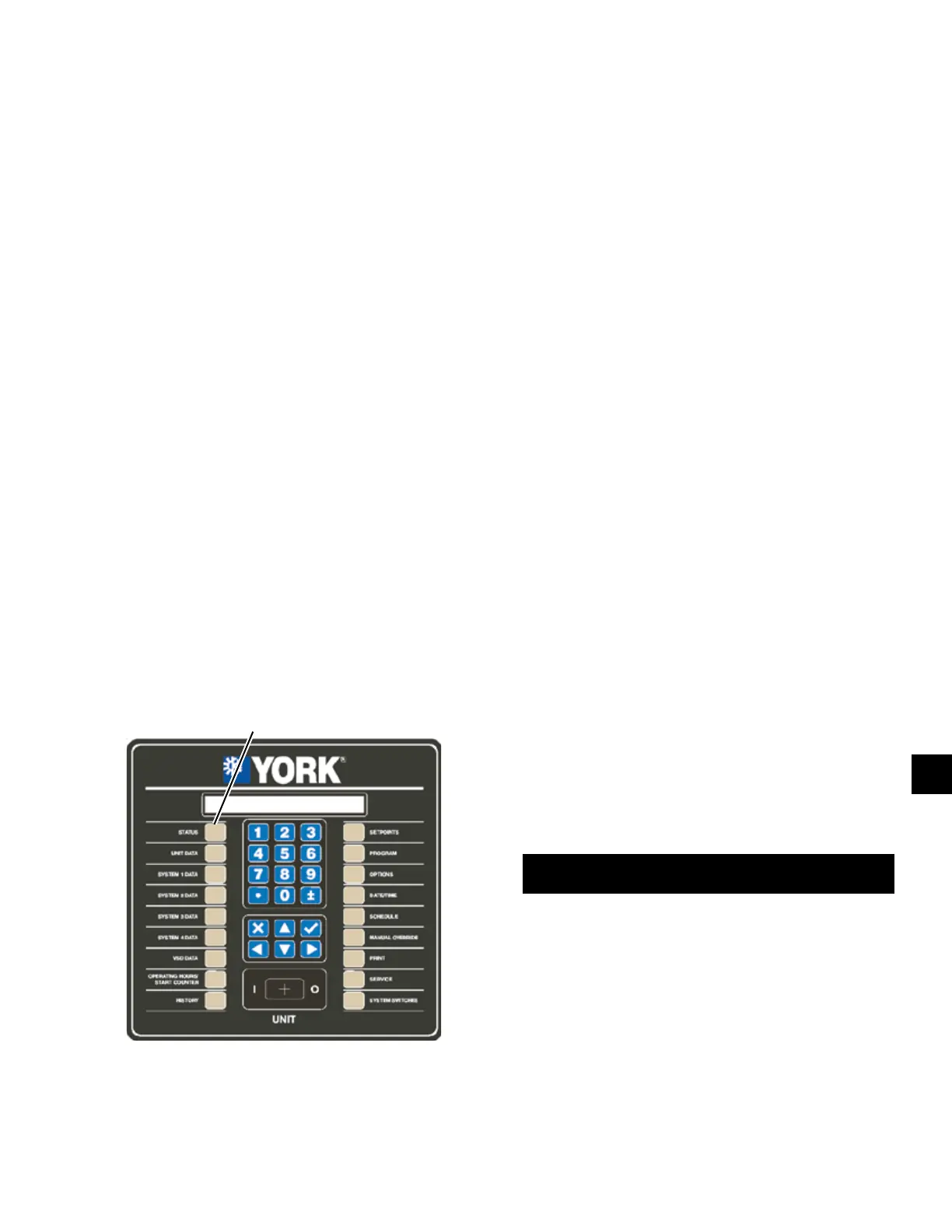

LD10605

STATUS

KEY

In some cases, a control panel fault will occur after

a VSD fault, possibly during system shutdown or at

some later time. This is known as an “ALL FAULT”

and these faults will be recorded as such under the

HISTORY information stored at the instant of the pri-

mary fault. In some cases, this information may be

valuable in troubleshooting the primary fault. An ex-

ample of the “ALL FAULT” history message is shown

on Page 263 under the HISTORY key. When an “ALL

FAULT” occurs, associated history information will

not be stored. If an additional fault does not occur, the

“ALL FAULTS” display will indicate NONE. In cases

where a VSD fault occurs during the rampdown of a

control panel fault (i.e.: low suction pressure, low wa-

ter temp, etc.), the VSD fault will be stored as a new

fault with the associated fault information stored at the

instant the VSD fault occurred (i.e.: IGBT Gate Drive,

Single Phase Input, VSD CT Plug, etc.). The control

panel fault that occurred prior to the VSD fault will be

stored with the associated complete data related to the

fault as a numerically lower numbered history in the

history buffers.

High Discharge Pressure Cutout (Software)

Fault

The High Discharge Pressure Cutout is a software

fault. A system will fault and shut down with a con-

trolled ramped shutdown on high discharge pressure

when the discharge pressure rises above 274 psig for

0.5 seconds. The system will be allowed to restart

when the discharge pressure falls to 259 psig. The sys-

tem will also be inhibited from starting if the pressure

is above 259 psig. The fault message for this safety is

shown below:

SYS X YYYYYYYY HIGH DISCHARGE PRESSURE

X indicates the system and YYYYYYYY indicates

the system is in a “FAULT” condition and will restart

when the 120 second anti-recycle timer times out, or

“LOCKOUT” and will not restart until the operator

clears the fault using the keypad.

Loading...

Loading...