JOHNSON CONTROLS

229

SECTION 8 - MICROPANEL

FORM 201.23-NM2

ISSUE DATE: 09/25/2020

8

A fault acknowledge bit from the Chiller Control

Board is sent to the VSD via comms after receiving

valid fault data from the VSD. When the VSD Logic

Board receives the fault acknowledge via comms from

the panel it will reset (close) the Fault Relay. The fault

acknowledge is reset by the Chiller Control Board after

the Fault Relay is closed by the VSD Logic Board.

VSD Fault Compressor Start Inhibit

If a VSD fault condition exists while the compressor is

not running or pre-charging, the Chiller Control Board

will not try to start the faulted compressor(s). The start

inhibit will be automatically cleared when the fault

condition goes away.

UNIT WARNINGS

Unit Warning Operation

Unit warnings are caused when a condition is pres-

ent requiring operator intervention to restart the unit.

All setpoints, program values, and options should be

checked before operating the unit. Warnings are not

logged to the history buffer. If a unit warning is in

effect, the message will be displayed to the operator

when the STATUS key is pressed.

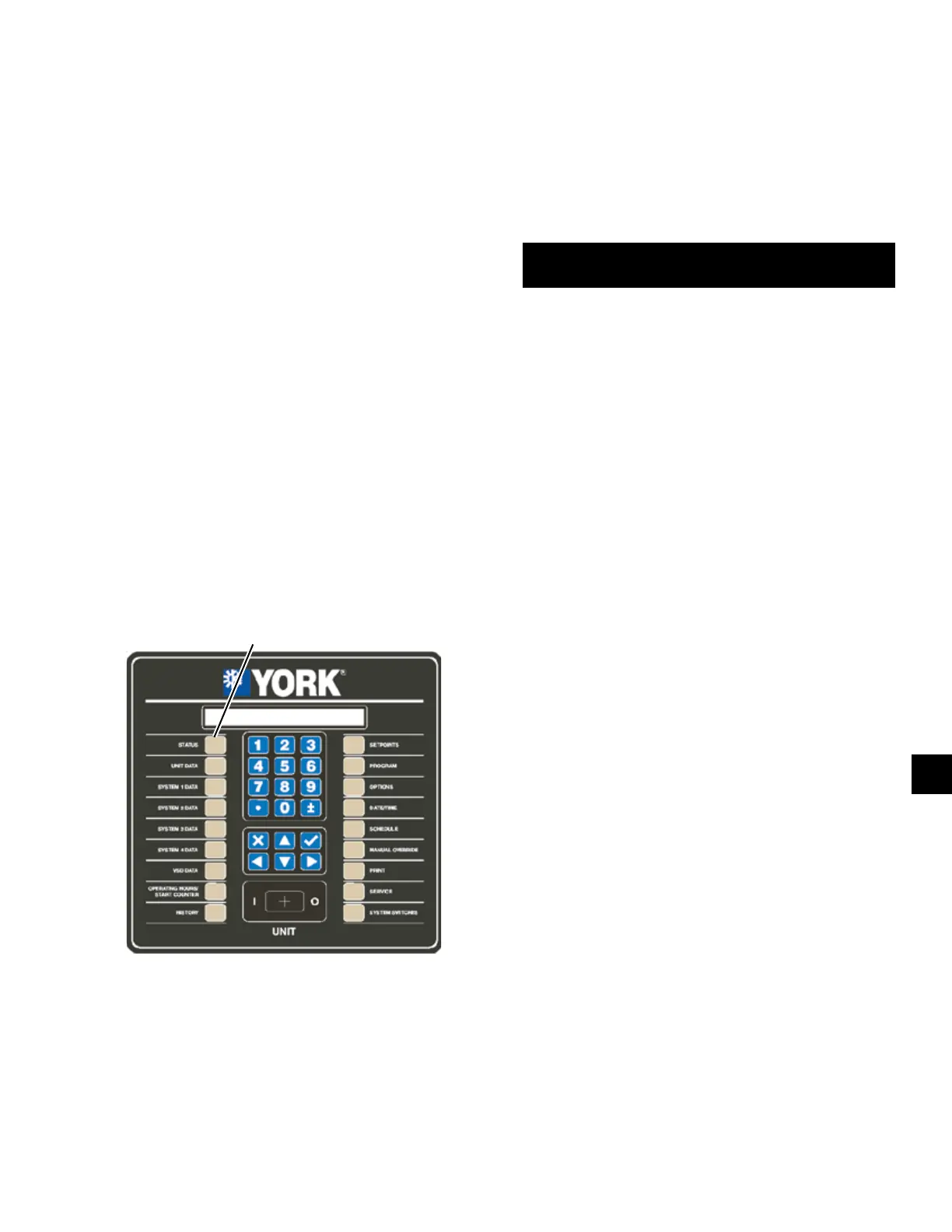

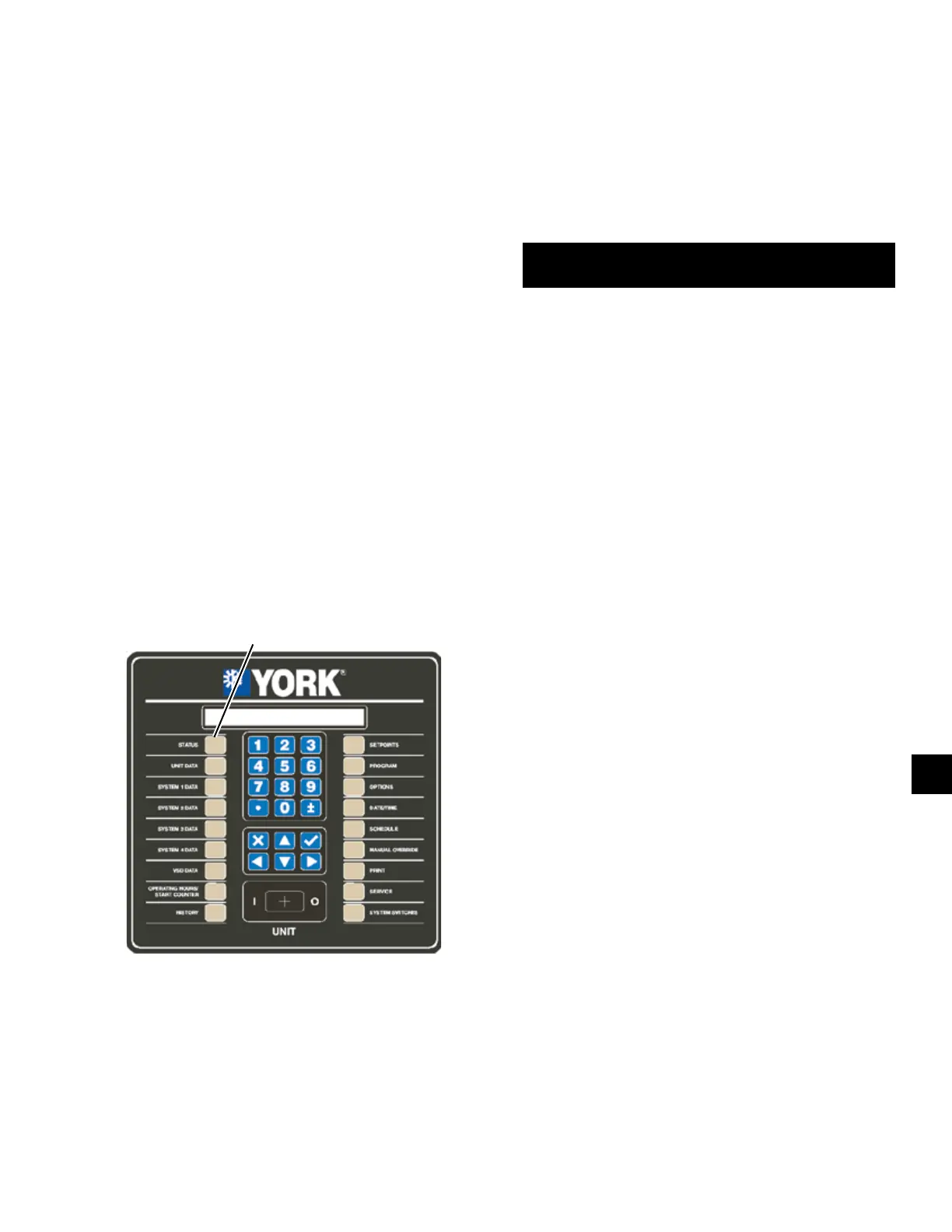

LD10605

STATUS

KEY

Low Battery Warning

The LOW BATTERY WARNING can only occur at

unit power-up. On micropanel power-up, the RTC bat-

tery is checked to see if it is still operational. If it is,

normal unit operation is allowed. If the battery voltage

is determined to be low, the following warning mes-

sage is displayed indefinitely.

UNIT WARNING: !! LOW BATTERY !!

CHECK SETPOINTS/PROGRAM/OPTIONS/TIME

If a low battery condition exists, all programmed

setpoints, program values, time, schedule, and history

buffers will have been lost. These values will all be re-

set to their default values, which may not be the desired

operating values. Once a bad battery is detected, the

unit will be prevented from running until the MANU-

AL OVERRIDE key is pressed. Once the MANUAL

OVERRIDE key is pressed, the anti recycle timers will

be set to the programmed default anti recycle time to

allow the operator sufficient time to check setpoints,

program values, etc.

If a low battery is detected, it should be replaced as

soon as possible. The programmed values will all be

lost and the unit will be prevented from running on the

next power interruption. The RTC/Battery is located on

the Chiller Logic Board shown in Figure 60 on page

230.

MICROBOARD (331-03478-XXX)

The 331-03478-xxx microboard was developed as a

direct replacement for the 031-02478-xxx line of mi-

croboards. No adapter harness is required when replac-

ing a 02478 with the new 03478. The 03478 uses the

IPUII processor card and provides some new features

for the chillers that the 02478 did not have. The 03478

program resides in flash memory instead of EPROM.

Program updates are accomplished by loading the new

program from an SD card inserted into the SD card

reader/writer. This same SD card reader/writer also al-

lows the user to datalog the operating parameters to an

SD card every 5 seconds. This information is invalu-

able when troubleshooting unit and system problems

since it allows the service technician to view operat-

ing parameters prior to a unit fault. Details on the new

datalogging capability are explained in the OPTIONS

Key area of this manual. A Real Time Clock/BRAM

keeps time and setpoints during power outtages.

Loading...

Loading...