JOHNSON CONTROLS

21

SECTION 2 - PRODUCT DESCRIPTION

FORM 201.23-NM2

ISSUE DATE: 09/25/2020

2

The power section of the drive is composed of four ma-

jor blocks consisting of an AC to DC rectifier section

with accompanying pre-charge circuit, a DC link filter

section, a three phase DC to AC inverter section, and

an output suppression network.

The AC to DC rectifier utilizes a semi-converter formed

by the connection of three SCR/diode modules (1SCR

through 3SCR) in a three phase bridge configuration.

The modules are mounted on a liquid cooled heatsink.

Use of the semi-converter configuration permits im-

plementation of a separate pre-charge circuit to limit

the flow of current into the DC link filter capacitors

when the drive is switched on and it also provides a

fast disconnect from the power mains when the drive is

switched off. When the drive is turned off, the SCR's in

the semi-converter remain in a non-conducting mode

and the DC link filter capacitors remain uncharged.

When the drive is commanded to run, the DC link filter

capacitors are slowly charged via the semi-converter.

The SCR’s are then gated fully on.

Three power fuses (1FU - 3FU), an optional circuit

breaker (1SW) and a standard 5% impedance minimum

3-phase line reactor connect the AC to DC converter to

the incoming power. Very fast semiconductor power

fuses are utilized to ensure that the SCR/diode module

packages do not rupture if a catastrophic failure were

to occur on the DC link. The SCR Trigger Board pro-

vides the gating pulses for the SCR’s as commanded by

the VSD Logic Board.

The DC Link filter section of the drive consists of a

group of electrolytic filter capacitors (C1-C6). This

capacitor bank effectively smoothes the ripple voltage

from the AC to DC rectifier while simultaneously pro-

viding a large energy reservoir for use by the DC to

AC inverter section of the drive. In order to achieve

the required voltage capability for the capacitor por-

tion of the filter, filter capacitor “banks” are formed by

connecting two groups of parallel capacitors in series

to form a capacitor “bank”. In order to assure an equal

sharing of the voltage between the series connected ca-

pacitors and to provide a discharge means for the ca-

pacitor bank when the VSD is powered off, “bleeder”

resistors (1RES and 2RES) are connected across the

capacitor banks.

Variable Speed Drive (VSD)

The VSD (variable speed drive) is a liquid cooled, tran-

sistorized, PWM inverter, which provides speed con-

trol to vary the speed of 2, 3 or 4 compressor motors.

The VSD changes the duration of the voltage pulses

supplied to the motor to enable control of compressor

speed to match the system load. A PWM generator, on

the VSD Logic Board, with a switching frequency of

3125 Hz modulates the voltage signal to provide a rela-

tively pulses constant V/F ratio. In some cases, the V/F

ratio is slightly modified to provide additional torque

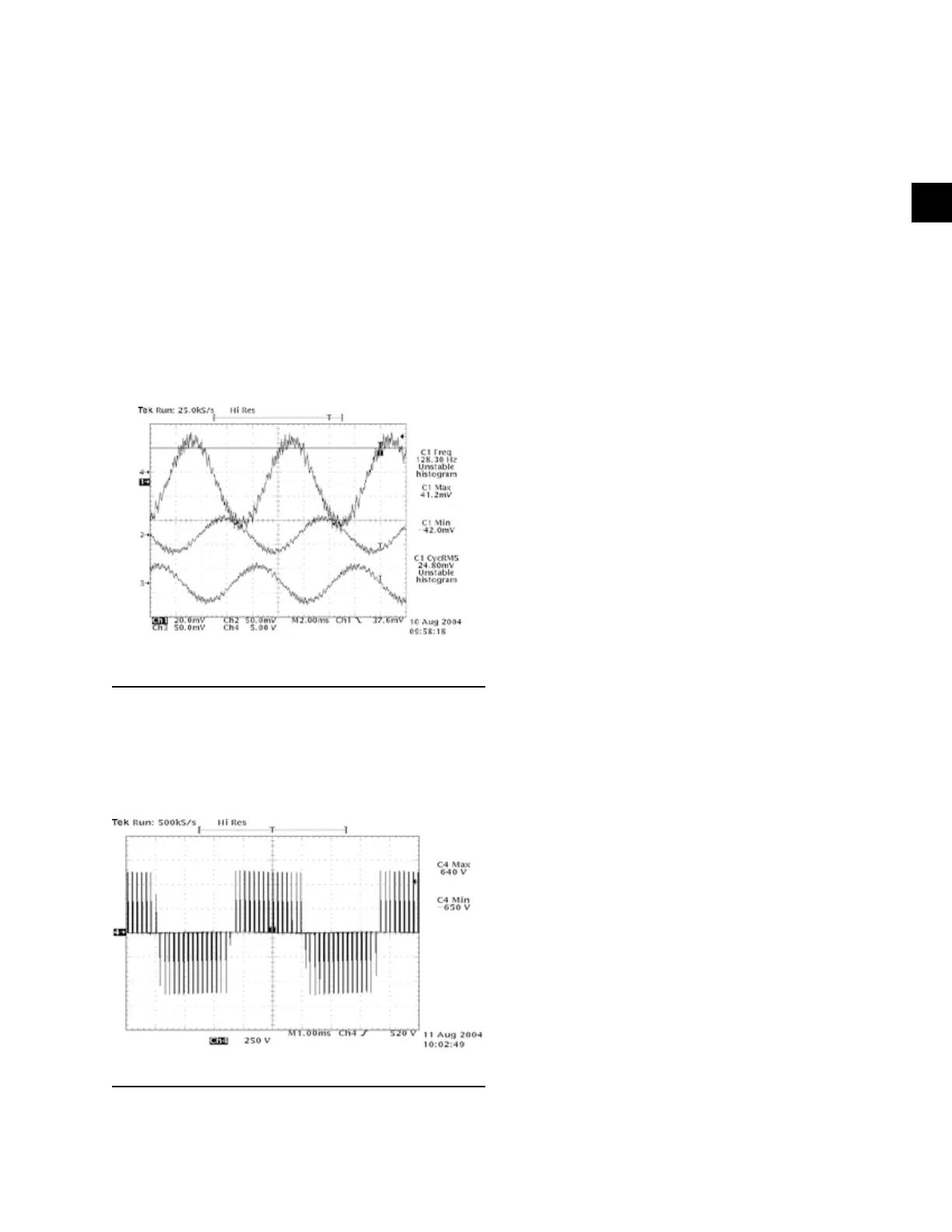

to the motor. Sample 3 phase current waveforms are

shown in Figure 3 on page 21 to show the sinusoidal

characteristics of the current drawn by the compressor

motors.

FIGURE 3 - PWM CURRENT WAVEFORM

LD10479

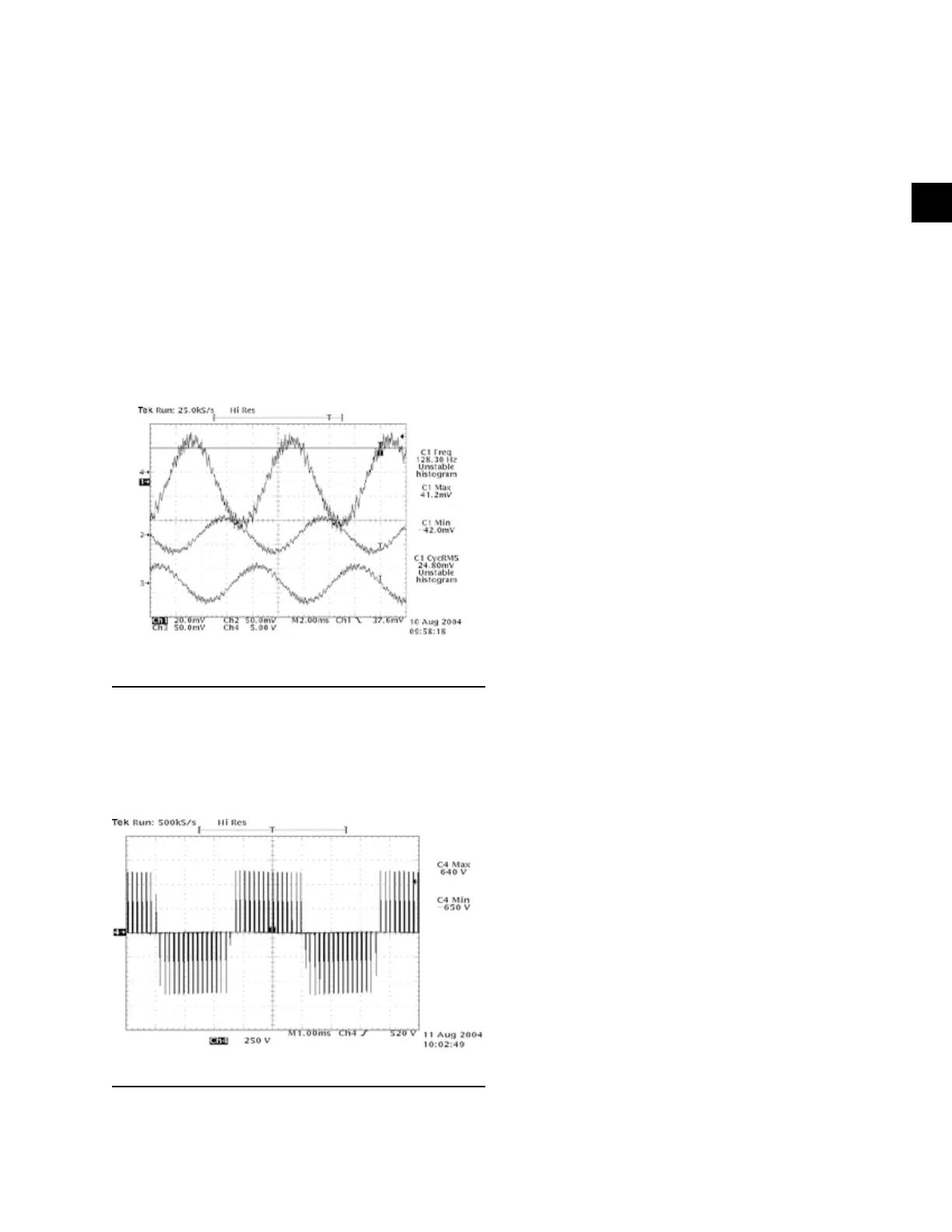

A Sample PWM voltage waveforms is shown in Figure

4 on page 21. The pulses near the sides of the rectan-

gular groups of waves are notably narrower, represent-

ing the lower voltage of a sinusoidal waveform as it

rises or falls from the “0” crossing.

FIGURE 4 - PWM VOLTAGE WAVEFORM

LD10480

Loading...

Loading...