44

ZQ220 User Guide

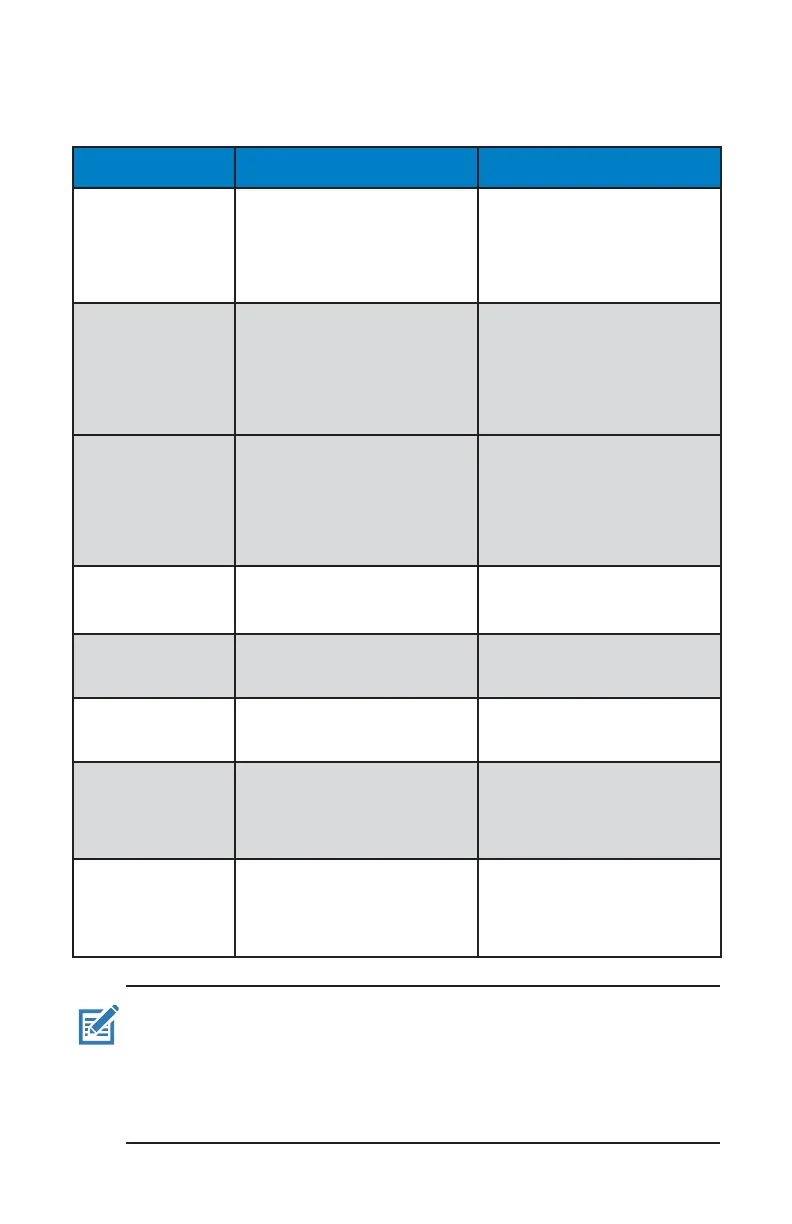

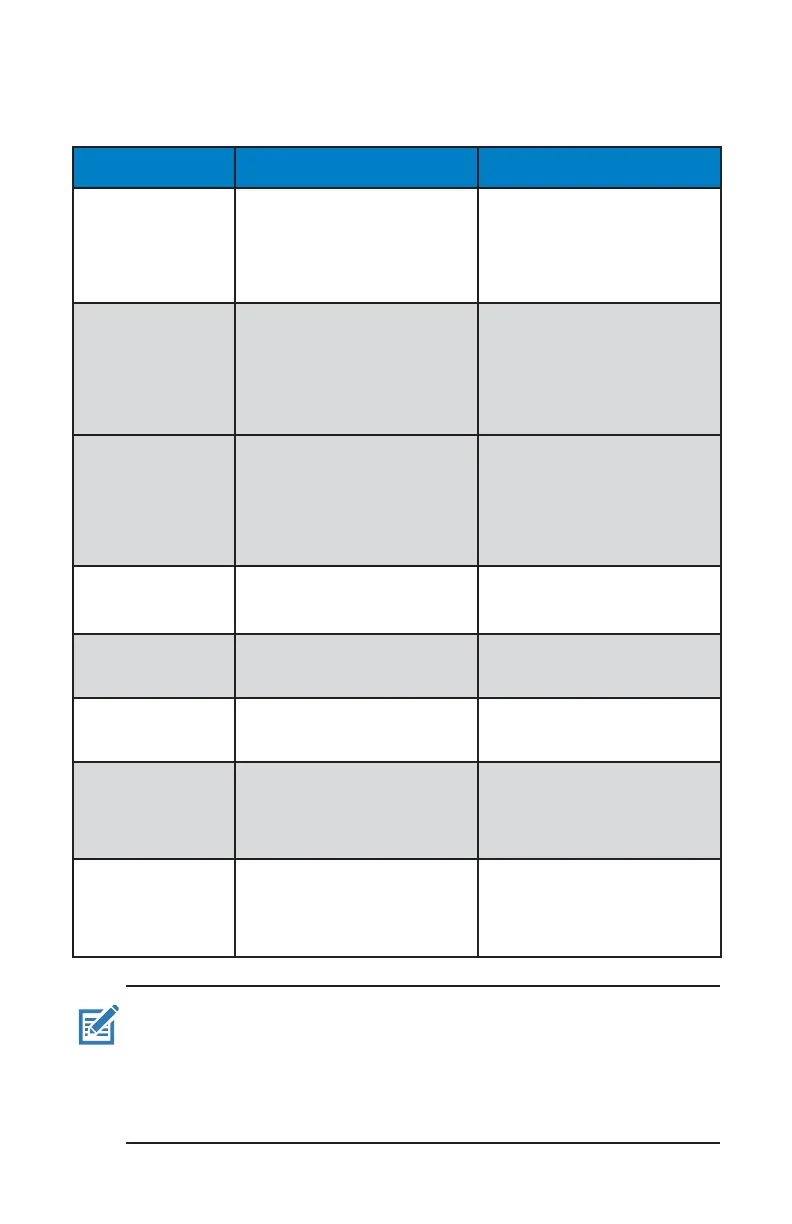

Cleaning

Area Method Interval

Printhead Use a Zebra cleaning pen to

swab the thin gray line on the

printhead, cleaning the print

elements from the center

to the outside edges of the

printhead.

After every ve rolls of media

(or more often, if needed).

When using linerless type

media, cleaning is required

after every roll of media.

Platen Surface

(Linered)

Rotate the platen roller and

clean it thoroughly with a

ber-free swab, or lint free,

clean, damp cloth lightly

moistened with medical

grade alcohol (90% pure or

better) (Figure 19).

After every ve rolls of media

(or more often, if needed)

Platen Surface

(Linerless)

Rotate platen roller and

clean with a ber-free swab

and 1 part liquid soap

(Palmolive or Dawn) and 25

parts water. Use pure water

to clean after soap/water

mixture. (Figure 20)

Clean platen only if there is

an issue during printing, i.e.,

media not releasing from the

platen. (*See Note below.)

Scraper

(Linerless Units

Only)

Use adhesive side of media

to clean scraper on linerless

units. (Figure 20)

After every ve rolls of

media (or more often, if

needed).

Tear Bar Clean thoroughly with 90%

medical grade alcohol and a

cotton swab. (Figure 19)

As needed

Printer Exterior Water-dampened cloth or

90% medical grade alcohol

wipe.

As needed

Printer Interior Gently brush out printer.

Ensure the Backside Sensor

and Frontside Sensor

windows are free of dust.

(Figure 19)

As needed

Interior of units

with Linerless

Platens

Clean thoroughly with 90%

medical grade alcohol and

a ber-free swab. (See

Figure 20 for specic target

areas for interior cleaning.)

After every ve rolls of media

(or more often, if needed).

Note • This is an emergency procedure only to remove foreign

contaminates (oils, dirt) from the platen that can damage the

printhead or other printer components. This procedure will shorten

or even exhaust the linerless platen’s useable life. If the linerless

media continues to jam after cleaning and feeding 1 to 2 meters (3 to

5 feet) of media, replace the platen.

Loading...

Loading...