A/C

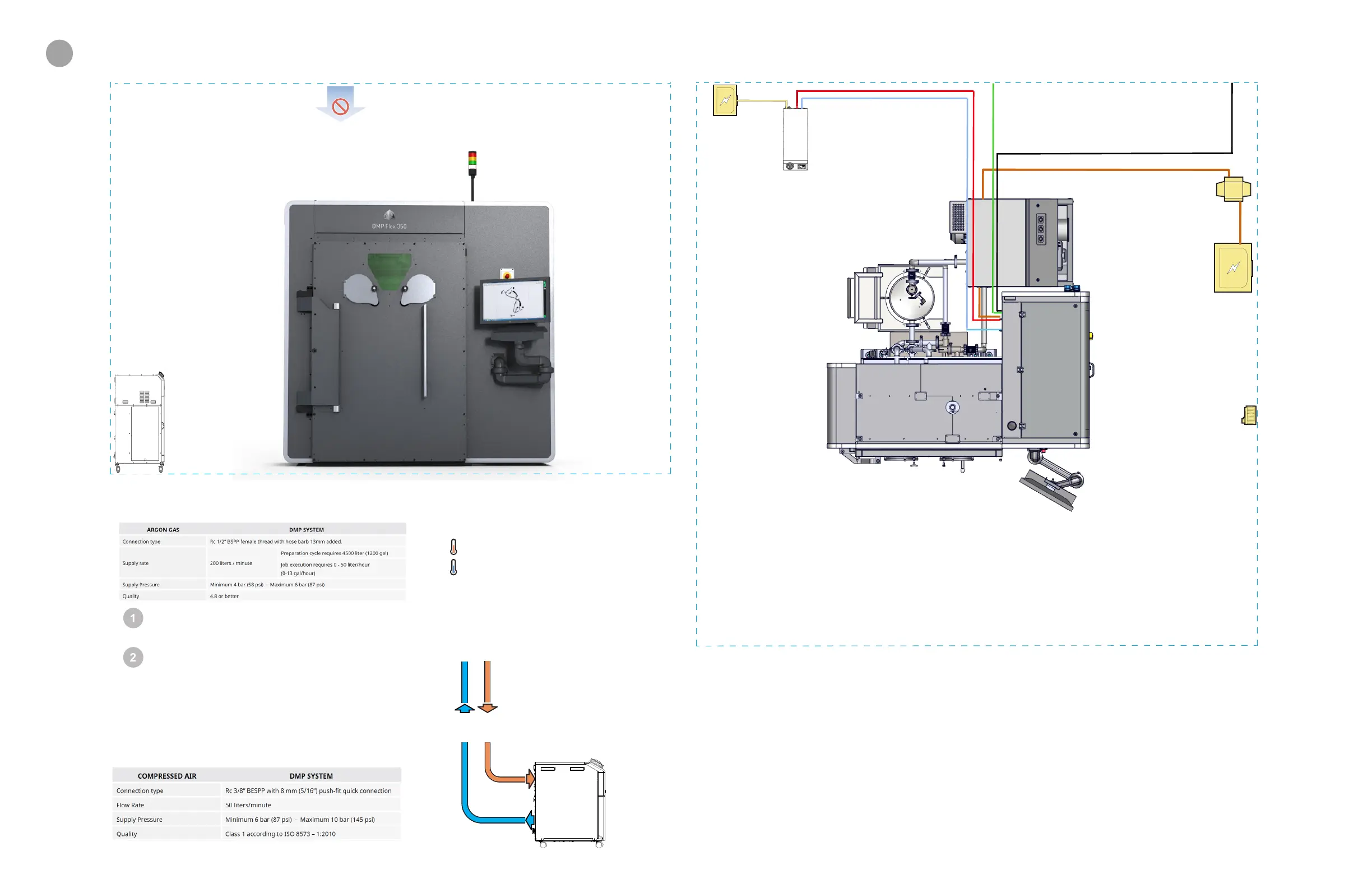

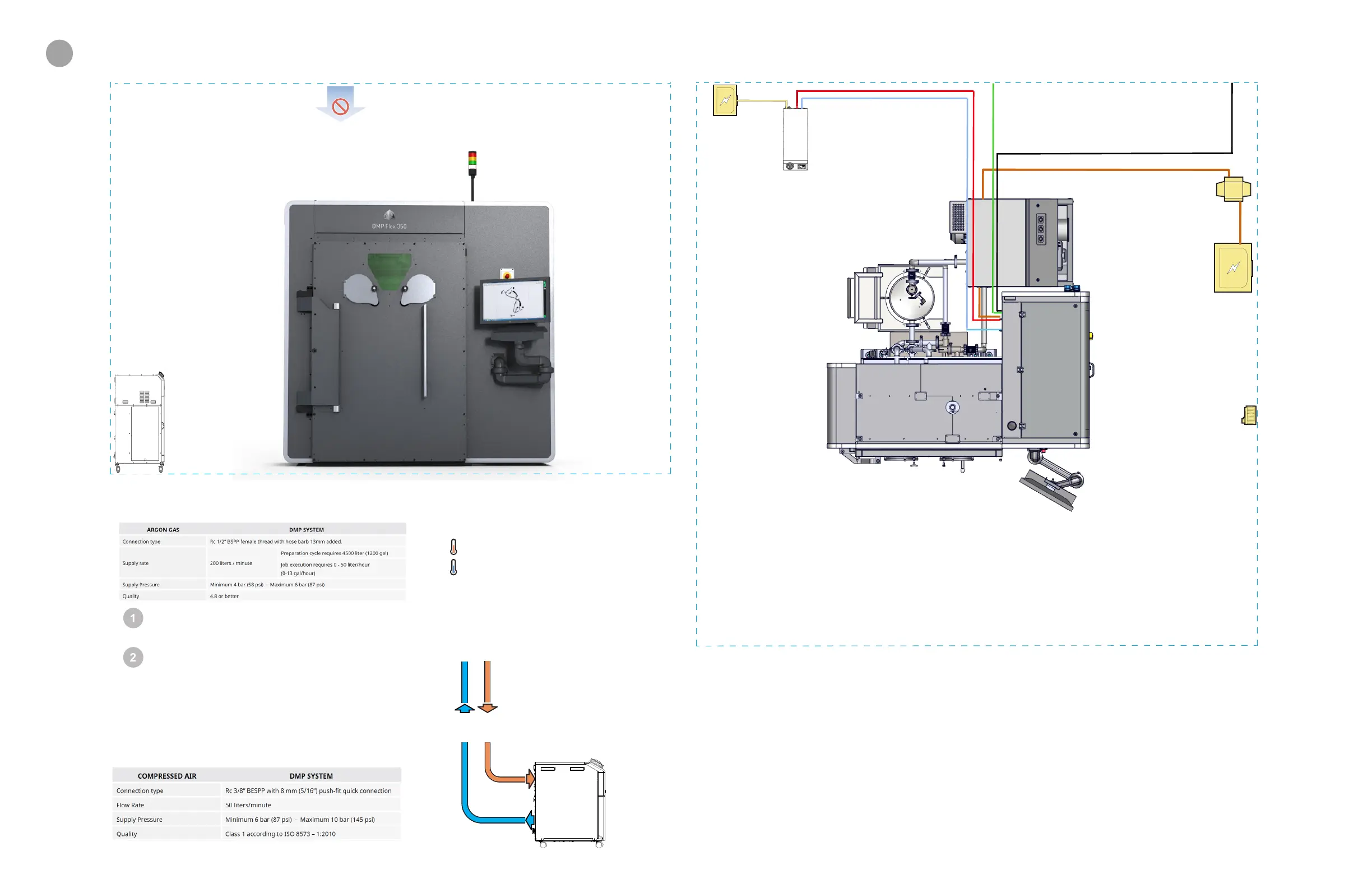

Argon Gas

min

16° C (60° F)

27° C (80° F)

max

Atmosphere

CHILLER

Chiller power

• Separate from

DMP Flex 350

• 200 to 230 VAC

• 50/60 Hz

• 15 kVA

• C

ustomer supplied/installed

Argon

• Customer supplied/installed

Room oxygen monitor

• Recommended

• Customer supplied/installed

Room temperature

setpoint and stability

• Set temperature between 18° C and 24° C (65° F and 75° F)

• Temperature should be constant to ±2° C (± 5° F)

Coolant Hoses

▪ Included with 3D Systems-supplied chiller

▪ 1/2" barbed hose fitting

Argon cylinders

▪ Use a high volume pressure reducer

▪ Connect cylinders with auto-switching

manifold to ensure constant argon

supply during build

Bulk Argon tank

▪ Option for high argon demand sites

Compressed Air

Air Conditioning

• Required

• Do not install vent directly above process station!

Compressed air

• Customer supplied/installed

Electrical cable

• Customer supplied/installed

Transformer

(optional)

Control cabinet

power panel

• 400 VAC

• 50/60 Hz

• 10 kVA

FACILITY REQUIREMENTS POSTER - COMPACT INSTALLATION

Loading...

Loading...