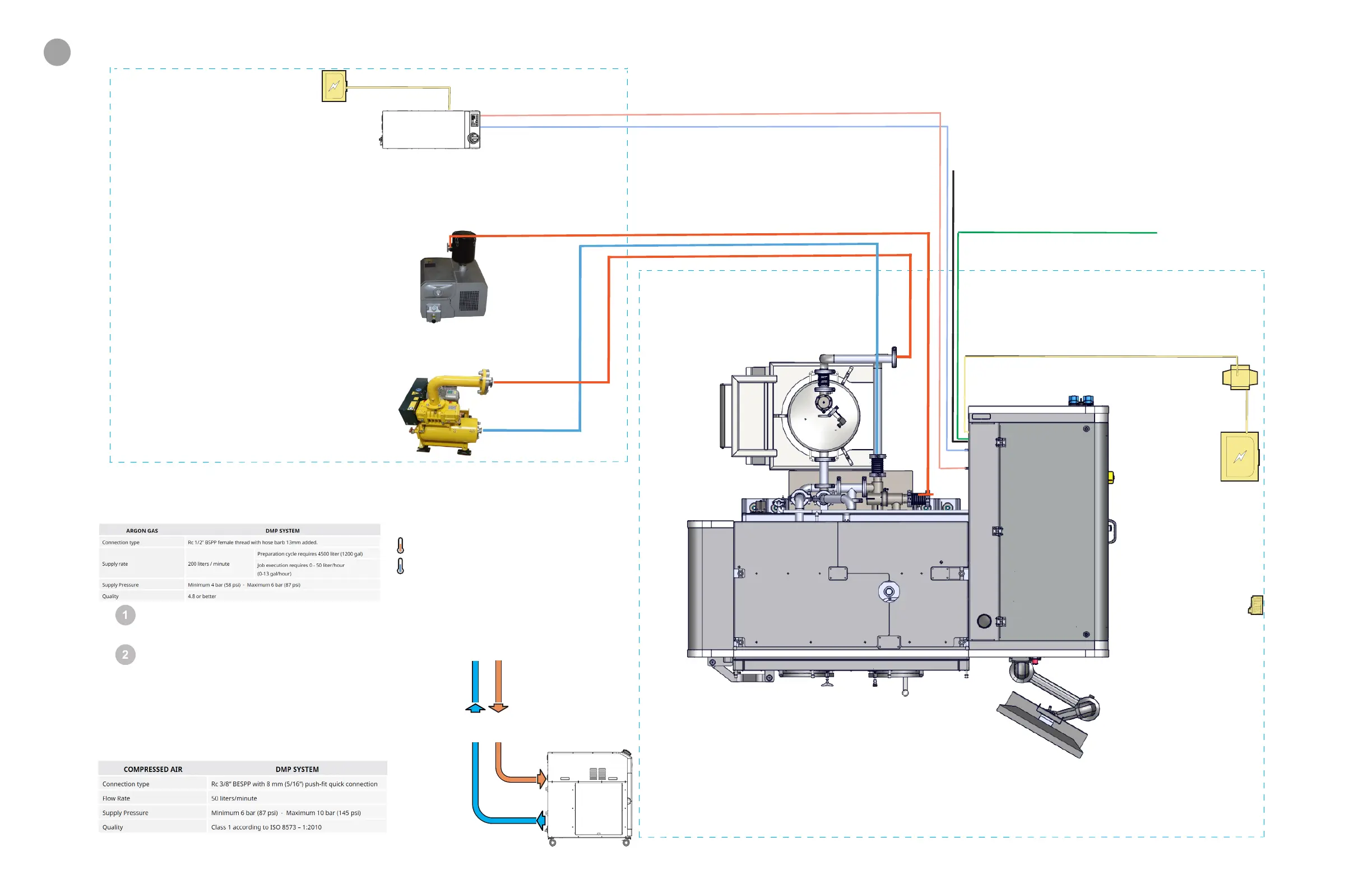

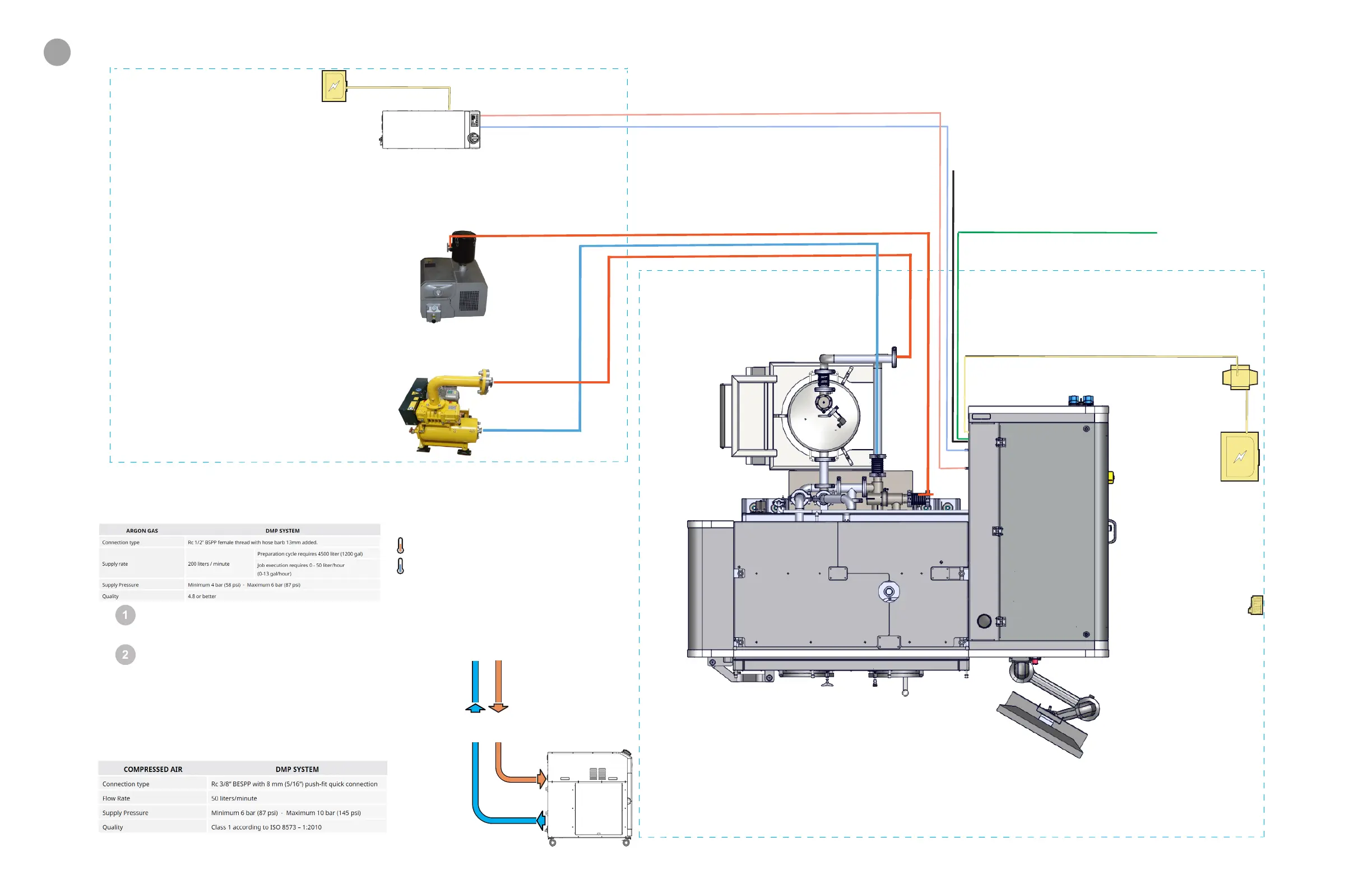

Control Cabinet

power panel

• 400 VAC

• 50/60 Hz

• 10 kVA

Build Room

Technical Room

Chiller power

• Separate from

DMP Flex 350

• 200 to 230 VAC

• 50/60 Hz

• 15 Amp

• C

ustomer supplied/installed

Additional argon gas line

• Customer supplied

Additional compressed air line

• Customer supplied

Additional signal cabling

• Customer supplied

Additional power cabling

• Customer supplied

Additional piping for vacuum pump and blower

• Customer supplied

• Maximum length is 10 meters

• Pipe must be stainless steel (303 or 304 is recommended)

• Customer must supply welding personnel

Transformer

(optional)

Room oxygen monitor

• Recommended

• Customer supplied/installed

Argon

• Customer supplied/installed

Compressed Air

• Customer supplied

/installed

Electrical Cable

• Customer supplied

/installed

Argon Gas

Bulk Argon tank

▪ Option for high argon demand sites

Argon cylinders

▪ Use a high volume pressure reducer

▪ Connect cylinders with auto-switching

manifold to ensure constant argon

supply during build

Compressed Air

min

16° C (60° F)

27° C (80° F)

max

Room temperature

setpoint and stability

• Set temperature between 18° C and 24° C (65° F and 75° F)

• Temperature should be constant to ±2° C (± 5° F)

Atmosphere

Coolant Hoses

▪ Included with 3D Systems-supplied chiller

▪ 1/2" barbed hose fitting

FACILITY REQUIREMENTS POSTER - SPLIT INSTALLATION

Loading...

Loading...