9. Each day that a processed 1492VBI is incubated, activate and incubate at least

one non-processed 1492VBI to use as a positive control. Follow the activation

instructions provided in Step 8 above. Write a "C" (for "control") and the date

on the BI label. The positive control should be from the same lot code as the

processed biological indicator. The positive control BI helpsconfirm:

• correct incubation temperatures aremet,

• viability of spores has not been altered due to improper storage temperature,

humidity or proximity tochemicals,

• capability of media to promote rapid growth,and

• proper functioning of the 490Auto-reader.

10. Incubation andReading:

Incubate the positive control and steam processed 1492VBIs at 56 ± 2°C in

a 490 Auto-reader. See the 490 Auto-reader Operator's Manual for the proper

use of this equipment. Positive results are available within 1 hour. The 490

Auto-reader will indicate a positive result as soon as it is obtained. The final

negative 1492VBI reading is made at 1 hour. After the results are displayed and

recorded, the 1492VBIs may bediscarded.

Interpretation ofResults

FluorescentResults

The positive control (unprocessed) 1492VBI must provide a positive fluorescent

result (+ on the 490 Auto-reader LCD display). Processed 1492VBI results are

not valid until the positive control reads fluorescent positive. The positive control

should read positive (+ on the LCD display) at or before 1hour. If the positive

control reads negative (- on the LCD display) at 1 hour, check the 490 Auto-reader

Operator’s Manual Troubleshooting Guide. Retest the 490 Auto-reader with a new

positivecontrol.

With processed 1492VBIs, a positive (+ on the LCD display) result indicates a

sterilization process failure. A final negative processed 1492VBI reading (- on the

LCD display) after 1hour of incubation indicates an acceptable sterilizationprocess.

Act immediately on any positive results for processed BIs. Determine the cause of

the positive BI following facility policies and procedures. Always retest the sterilizer

and do not use sterilizer for processing loads until three consecutive BI results

arenegative.

Optional Visual pH Color ChangeResult

The 1492VBI is normally discarded after the fluorescent result has been recorded. If,

however, special studies are desired, 1492V BIs may be further incubated for a visual

pH color change result. After activation and during incubation, the white Nonwoven

Material will absorb the bromocresol purple indicator, the pH-sensitive indicator dye

in the growth media, and appear blue. In the case of the positive control BI a yellow

color change of the growth media and/or Nonwoven Material will appear within 48

hours. Any observation of a yellow color within the vial indicates a positiveresult.

In the case of a processed 1492VBI, a media and/or Nonwoven Material color

change from purple to yellow indicates a sterilization process failure. A negative pH

color change result, i.e., media and Nonwoven Material remain purple/blue, can be

assessed at 48hours.

Storage

• Best stored in original box under normal room conditions: 59-86ºF (15-30ºC),

35-60% relative humidity (RH).

• Do not store 1492VBIs near sterilants or otherchemicals.

Disposal

Dispose of used 1492VBIs according to your health care facility policy.You may wish

to steam sterilize any positive biological indicators at 132°C (270°F) for 4minutes

or at 275°F (135°C) for 3minutes in a dynamic-air-removal steam sterilizer prior

todisposal.

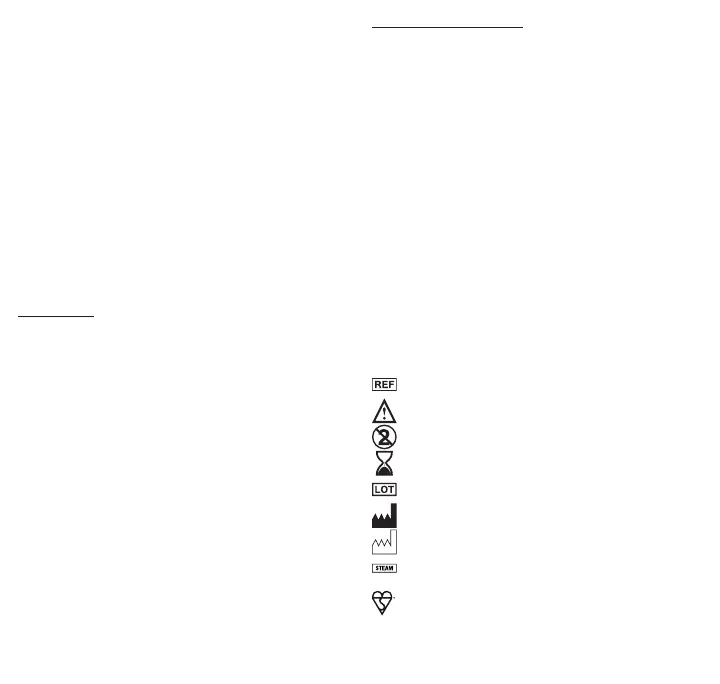

Explanation of Symbols

Catalogue Number

Caution, see instructions for use

Do not reuse

Use by date

Batch code

Manufacturer

Date of manufacture

Product is designed for use with steam sterilizationcycles.

British Standards Institution (BSI) Kitemark™ License for compliance with

BS EN ISO 11138-1:2006 and BS EN ISO 11138-3:2009

Loading...

Loading...