26 266CRH / 266CRT, 266CSH / 266CST MULTIVARIABLE PRESSURE TRANSMITTER | OI/266CXX/MODBUS-EN REV. A

… 6 Installation

… Adjusting the transmitter position

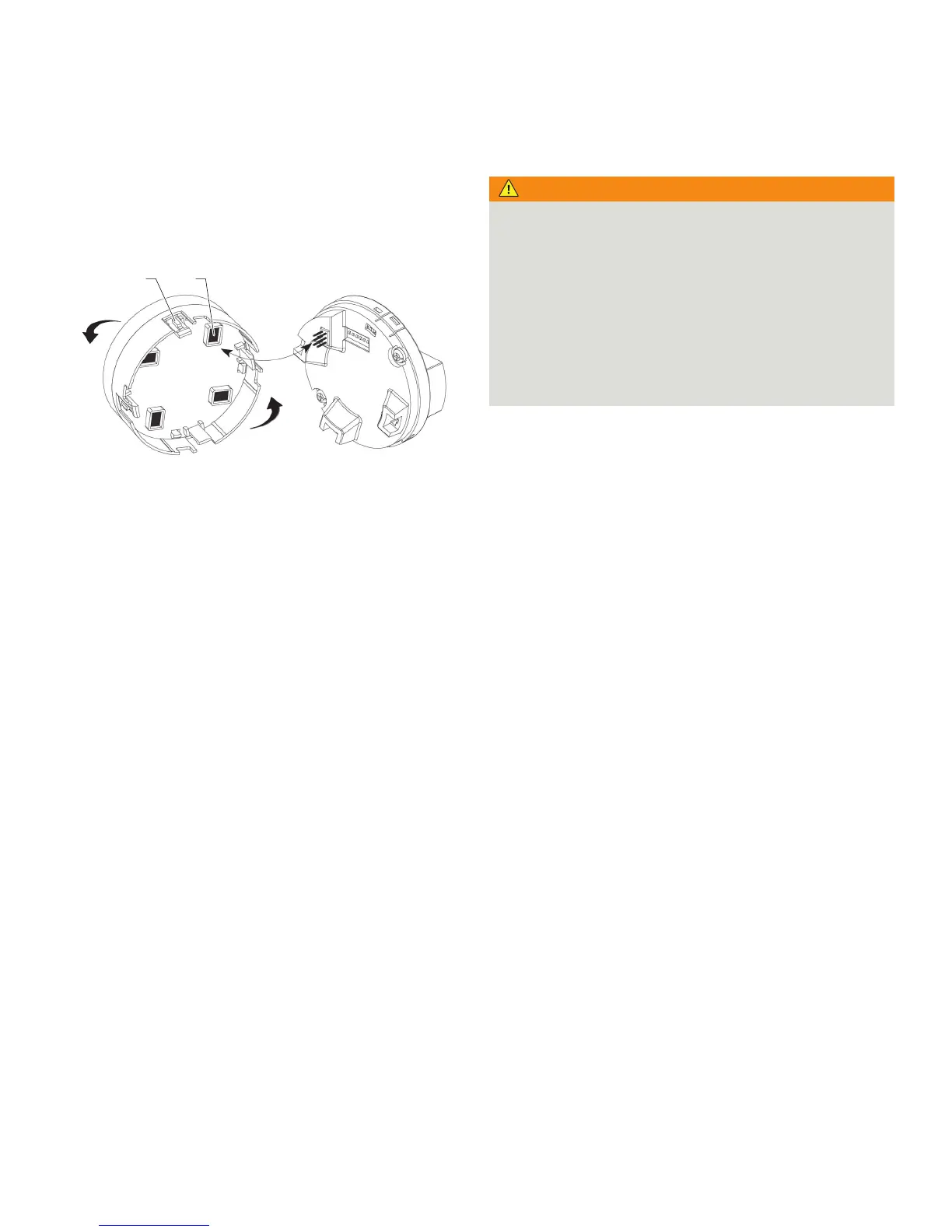

Rotate the LCD display

If the device has an integral LCD display, this can be mounted in

four different positions, each of which can be rotated

through 90°.

M10760-01

1 2

1 Fixing locks

2 Display connector

Figure 16: Rotating the LCD display

To rotate the LCD display, perform the following steps:

1.2pen the windowed cover (ensuring compliance with

special requirements for hazardous areas), Refer to

Opening and closing the housing on page 25.

2. Pull the LCD display out of the electronics module.

3. Reposition the LCD display connector accordingly.

4. Plug the LCD display back into the electronics module,

checking that the 4 plastic fixing locks are securely in

place.

5. Close the windowed cover.

Connecting impulse lines

WARNING

Bodily injury!

Leaks in the process lines can result in death or severe

injuries.

• Install and seal process connections and all accessory

elements (including valve blocks) before the charging the

device with pressure.

• For applications with toxic or hazardous substances prior

to venting or draining, take all precautionary measures

that are recommended in the respective safety data sheet.

• Only tighten the screws of the fastening accessories with

a size 12 mm (¹?32 in) hexagon socket wrench.

In order for the impulse lines to be laid correctly, the following

points must be observed:

• The impulse lines must be as short as possible and have

no sharp bends

• Lay the impulse lines so that no deposits can accumulate

in them. Gradients should not be less than approx. 8 %

(ascending or descending)

• The impulse lines should be blown through with

compressed air or, better still, flushed through with the

medium prior to connection

• With wet legs, the liquid in both lines must be at the same

level

• With vaporous measuring media, measures must be

taken to prevent steam entering the measuring chambers

of the measuring cell and causing overheating

• It may be necessary to use condensate vessels or similar

with small measuring spans and vaporous media

• If you are using condensate vessels (steam

measurement), you should ensure that the vessels are at

the same elevation in the differential pressure piping

• As far as possible, keep both impulse lines at the same

temperature

• Completely depressurize the impulse lines if the medium

is a liquid

• Lay the impulse lines so that gas bubbles (when

measuring liquids) or condensate (when measuring

gases) can flow back into the process line

• Ensure that the impulse lines are connected correctly

(connection of high-pressure and low-pressure sides to

the measuring cell, gaskets, etc.)

• All connections must be secure and tight

• Lay the impulse lines so that the medium cannot be

blown out over the measuring cell

For more details please read the operating instruction section

Mounting.

Loading...

Loading...