266CRH / 266CRT, 266CSH / 266CST MULTIVARIABLE PRESSURE TRANSMITTER | OI/266CXX/MODBUS-EN REV. A 83

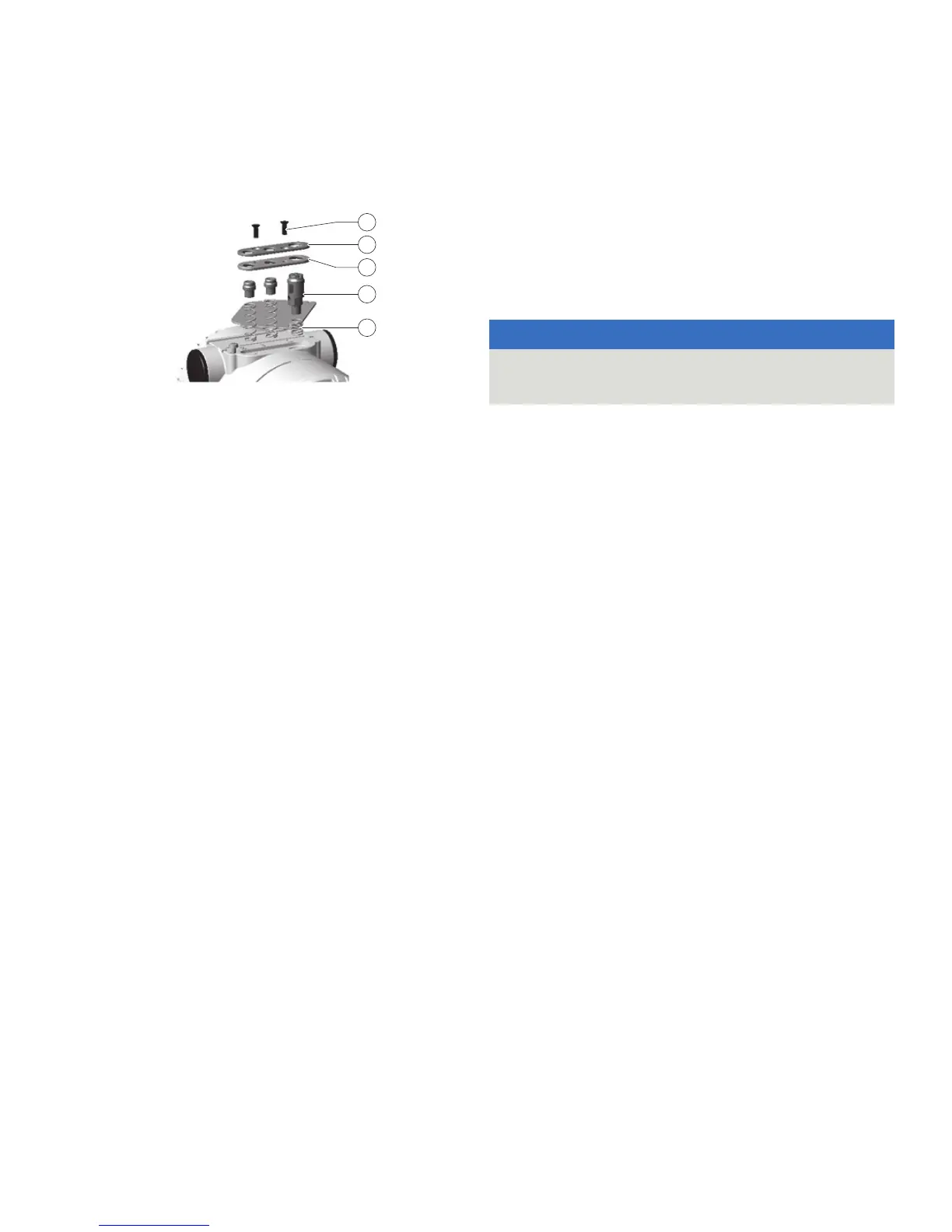

Mounting / dismounting the operating

button unit

M10804-01

1

2

3

4

5

Figure 4: Operating button unit

1. Unscrew the fastening screws of the name plate and swing

the name plate to the side to obtain access to the local

operating elements.

2. Unscrew the fastening screws

1 of the button unit that hold

the spring-loaded plastic part.

3. Remove the seal

3 that is located below the plastic cover of

the button unit.

4. Now the three operating buttons

4 and the springs 5 can

be taken out.

Mounting / dismounting the LCD display

Refer to Opening and closing the housing on page 25 and

Rotate the LCD display on page 26.

1. On the side of the electronics module / LCD display, unscrew

the housing cover.

2. Fit on the LCD display. Depending on the install position of

the multivariable transmitter, the LCD display can be fit on in

four different positions. Consequently it can be rotated by

± 90° or ± 180°.

3. Screw on the housing cover hand tight.

Removing / installing the process flange

1. Unscrew the fastening screws of the process flanges in cross

pattern (hexagon socket wrench AF 13 mm (0.51 in).

2. Carefully take off the process flanges so that the separating

diaphragms are not damaged.

3. Clean the separating diaphragms, and if necessary the

process flanges with a soft brush and a suitable cleaning

agent.

NOTICE

Potential damage to parts!

Components can be damaged using the wrong cleaning tools.

• Do not use any sharp-edged or pointed tools.

4. Insert new O-rings into the process flanges.

5. Fit the process flanges onto the measuring cell.

The flange surfaces of both process flanges must be

positioned in one plane and at right angles to the electronics

housing (vertical process flanges are the exception).

6. Check the thread of the screws for the process flanges for

ease of movement. To do this, screw on the nuts by hand to

the screw head. If this is not possible, use new screws and

nuts.

7. Lubricate the screw thread and the seat of the threaded

union, for example with ‘Anti-Seize AS 040 P’ (supplier:

WEICON GmbH & Co.KG, Münster, Germany).

Note

For the oil-free and grease-free version, after installation of the

process flange, the measuring chambers must be cleaned again.

8. Installation of the process flanges:

• First tighten the screws / nuts of the process flanges

with a torque wrench to a pre-tightening torque of MJ = 2

Nm (0.2 kpm), working in a cross pattern.

• Then tighten the screws / nuts of the process flanges

with a pre-tightening torque of MJ = 10 Nm (1.0 kpm),

working in a cross pattern.

• Retighten all screws / nuts (in a cross pattern), this time

with a total tightening angle of ήA = 180°; in two steps,

90° for each step.

Some transmitters have size M10 screws. Tighten these

screws with a total tightening angle of ήA = 270°; in three

steps, 90° each step.

Loading...

Loading...