30 266CRH / 266CRT, 266CSH / 266CST MULTIVARIABLE PRESSURE TRANSMITTER | OI/266CXX/MODBUS-EN REV. A

… 6 Installation

… Mounting recommendations

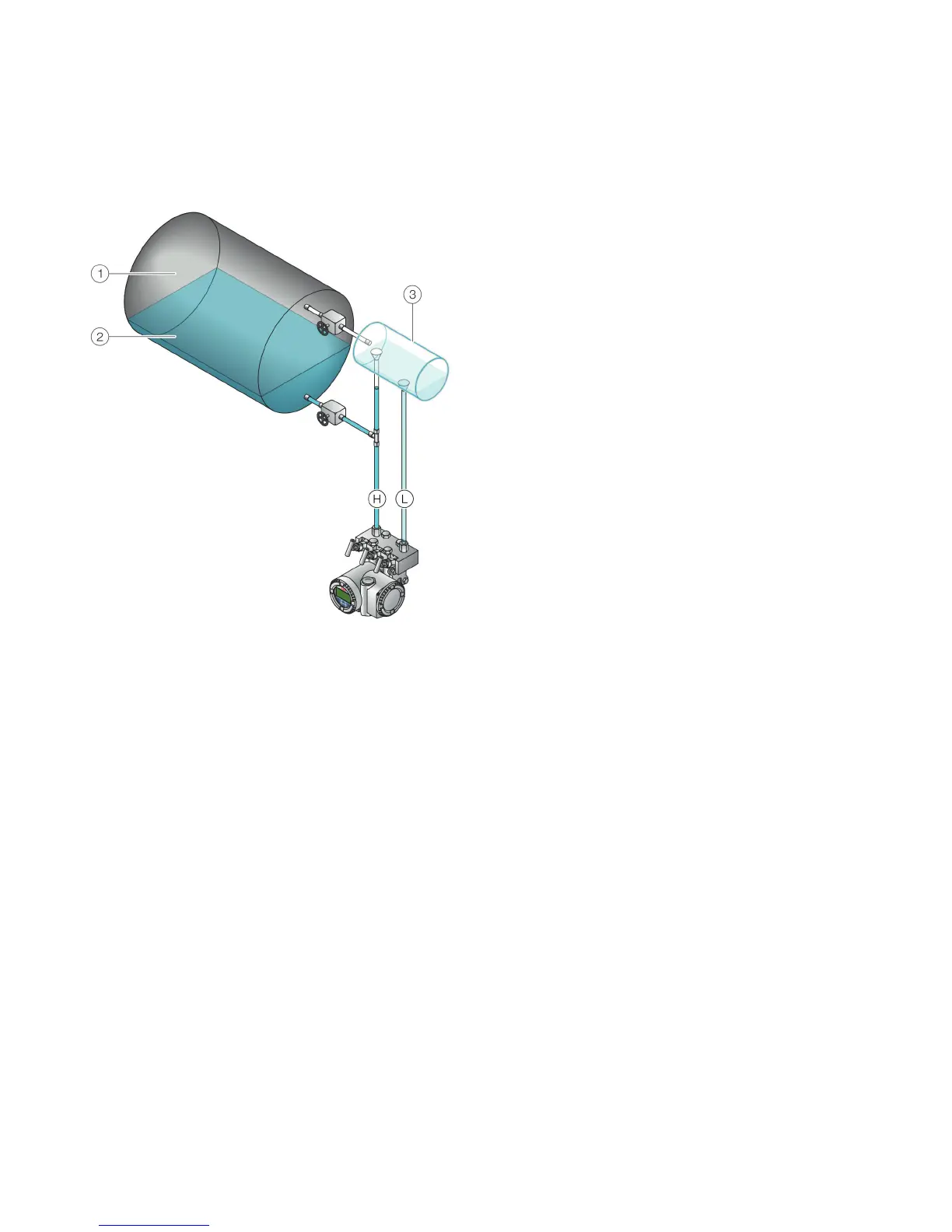

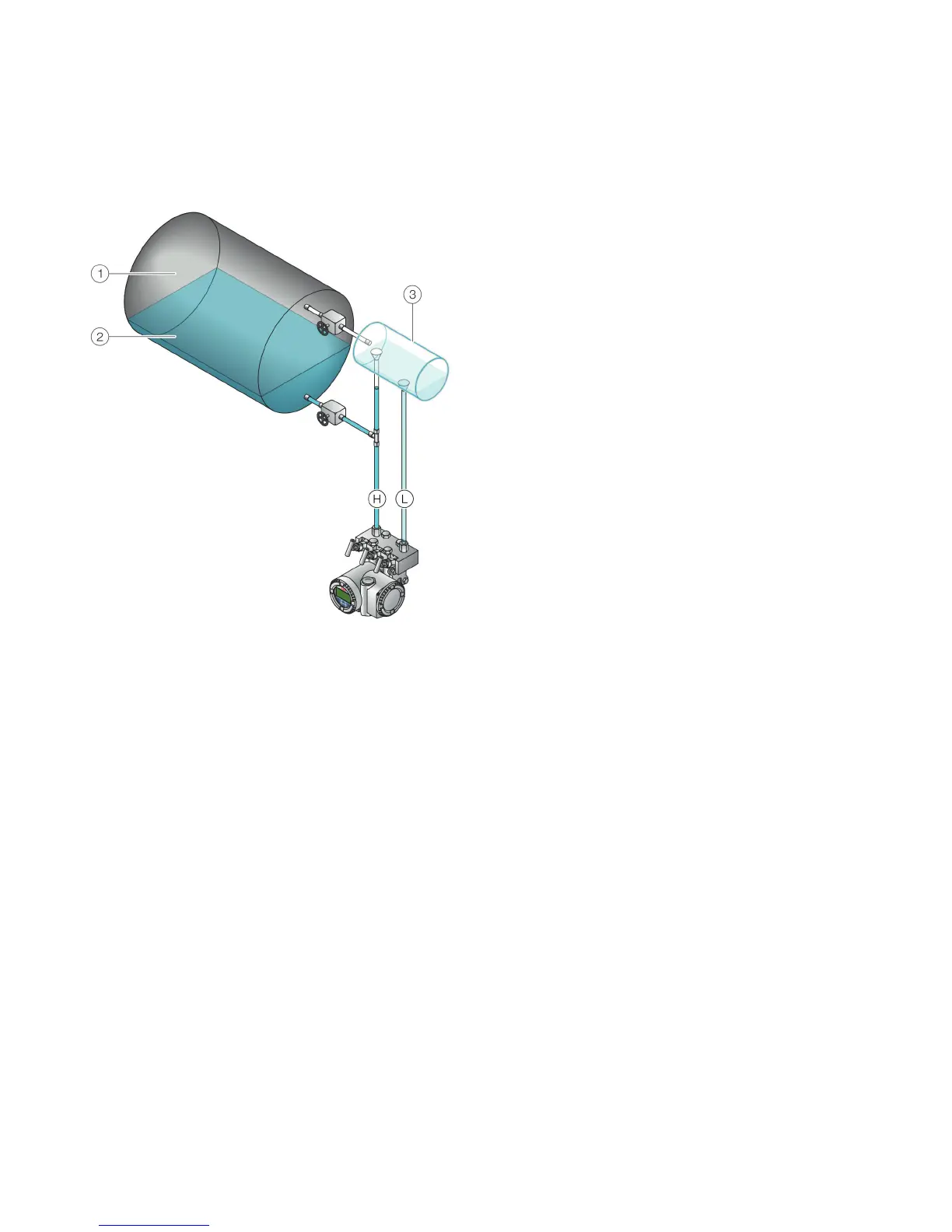

Fill level measurement on the steam boiler

(drum water level)

H High pressure side

L Low pressure side

1 Gas

2 Liquid

3 Condensate vessel

Figure 22: Level measurement on the steam boiler

• Mount the transmitter at the same height or below the

lowest level to be measured.

• Connect the high pressure side ‘+’ of the transmitter to the

bottom of the tank.

• The low pressure side ‘–’ of the transmitter up at the tank.

Above the maximum level, connect using a condensate

vessel.

• Use the condensate vessel to ensure that the impulse line of

the low pressure side is always filled with liquid (condensate)

at a constant height.

Temperature measurement

• Mount the temperature sensor in the downstream pipe of

the primary element.

• Consider the downstream straight pipe requirements.

• If there is a significant difference between the temperature

of the measuring medium and the ambient temperature, the

measuring error caused by heat conduction must be

minimized by insulating the installation location accordingly.

• Use class ‘A’ sensors to maximize accuracy.

• The lengths of the protective tubes should be 15 to 20 times

the diameter of the protective tube for gas measurements

and 3 to 5 times the diameter of the protective tube for

liquid measurements.

Loading...

Loading...