266CRH / 266CRT, 266CSH / 266CST MULTIVARIABLE PRESSURE TRANSMITTER | OI/266CXX/MODBUS-EN REV. A 37

Setting precalibrated devices

Note

266Cxx transmitters do not support this function if the ‘Level

measurement’ calculation function has been activated. In this

case, the correction must be made using the optional LCD

indicator or the DTM.

• For this purpose, the DIP switch on the electronics board

must be set to position ‘0’, see DIP switches on the

secondary electronics on page 38.

A PV Bias / Offset correction can be performed via the local push

buttons as follows:

1. Separate the transmitter from the process and equalize

the pressure in the two measuring chambers by adjusting

the bypass valve in the manifold.

2. Check the transmitter output signal:

• If it is PV = 0, zero point correction is not required.

• If the output is not at zero, proceed as follows:

3. Unscrew the screws attaching the name plate to the top

of the transmitter housing.

4. Rotate the name plate so that the push buttons can be

accessed.

5. Check that the write protection rotary switch is set to

write enable.

6. Press and hold down the zero button (Z) on the top of the

transmitter for at least 3 seconds.

• The output signal switches to PV = 0 and the message

‘OPER DONE’ appears on the LCD display (if there is one).

• If nothing happens, check the write protection rotary

switch.

It is probably set to write protection. For all other

diagnosis notices, refer to the instructions.

7. As soon as zero point correction is complete, reconnect

the transmitter to the process.

8. Open the pressure equalization valve on the manifold.

9. Open the shut-off valve of high-pressure side.

10.Open the pressure equalization valve on the manifold.

11. Open the shut-off valve on the low-pressure side.

Hardware settings

Write protection switch

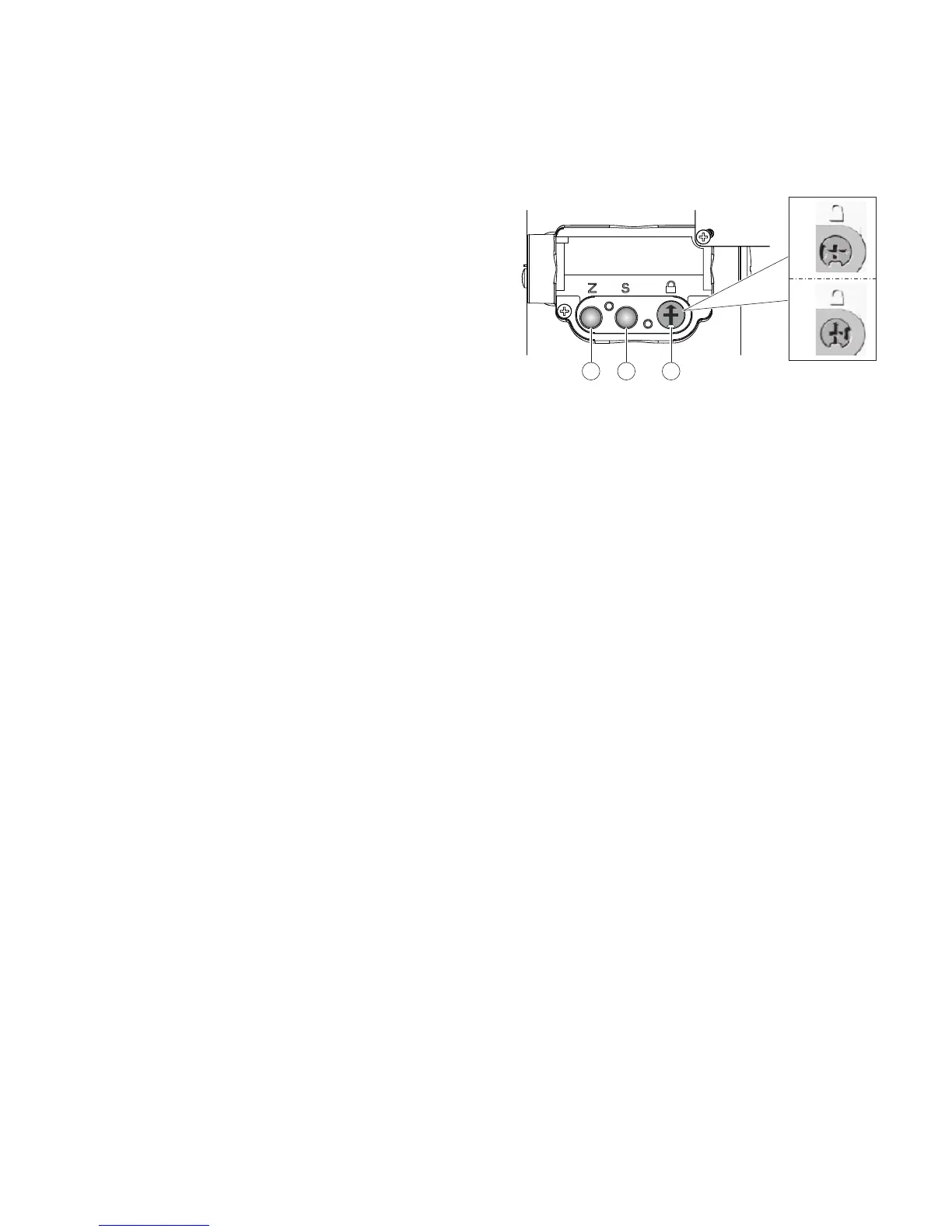

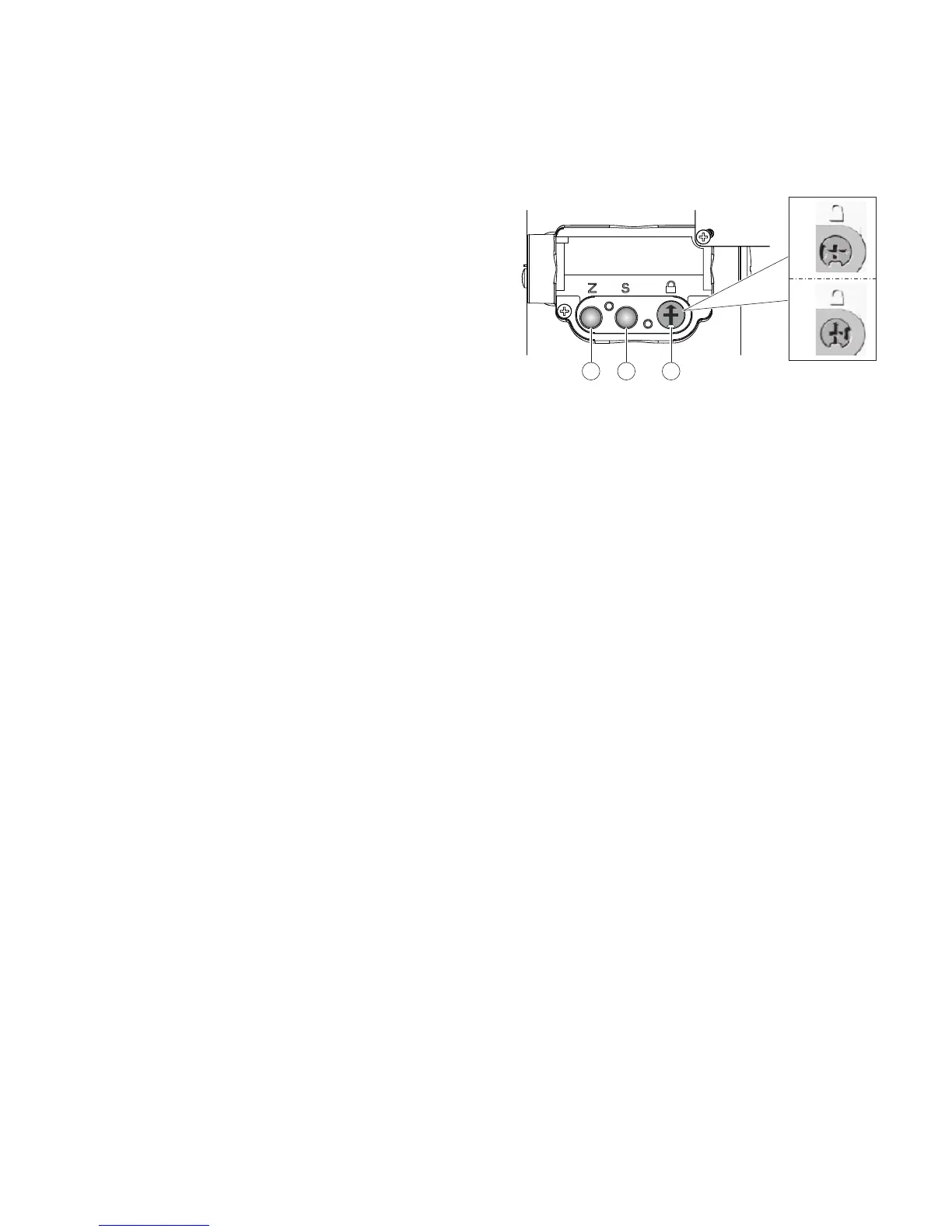

M10761-01

A

B

1

2

3

1 Zero

2 Span

3 Write protection switch

Figure 31: Operating buttons, write protection turn switch

The write protection prevents unauthorized users from

overwriting the configuration data.

• With activated write protection the operating buttons

‘0% (Z)’ and ‘100 % (S)’ have no function.

• A change of parameters with the integral LCD indicator, via a

handheld terminal, or the user interface (DTM) are not

possible either.

However, the configuration data can be read out via the graphic

user interface (DTM) or a comparable communication tool. If

needed the operating device can also be sealed with a lead seal.

Write protection can be activated as follows (see also the

symbols on the plate).

1. Remove the nameplate by releasing the holding screw lying

on the bottom left corner

2. Use a suitable screwdriver to press the switch all the way

down.

3. Turn the switch 90° clockwise.

Note

To deactivate write protection, press the switch down slightly

and then turn it counterclockwise 90°.

Note

The product has an ABB service account that can be disabled

with this write protection switch.

Loading...

Loading...