266CRH / 266CRT, 266CSH / 266CST MULTIVARIABLE PRESSURE TRANSMITTER | OI/266CXX/MODBUS-EN REV. A 27

Process connections

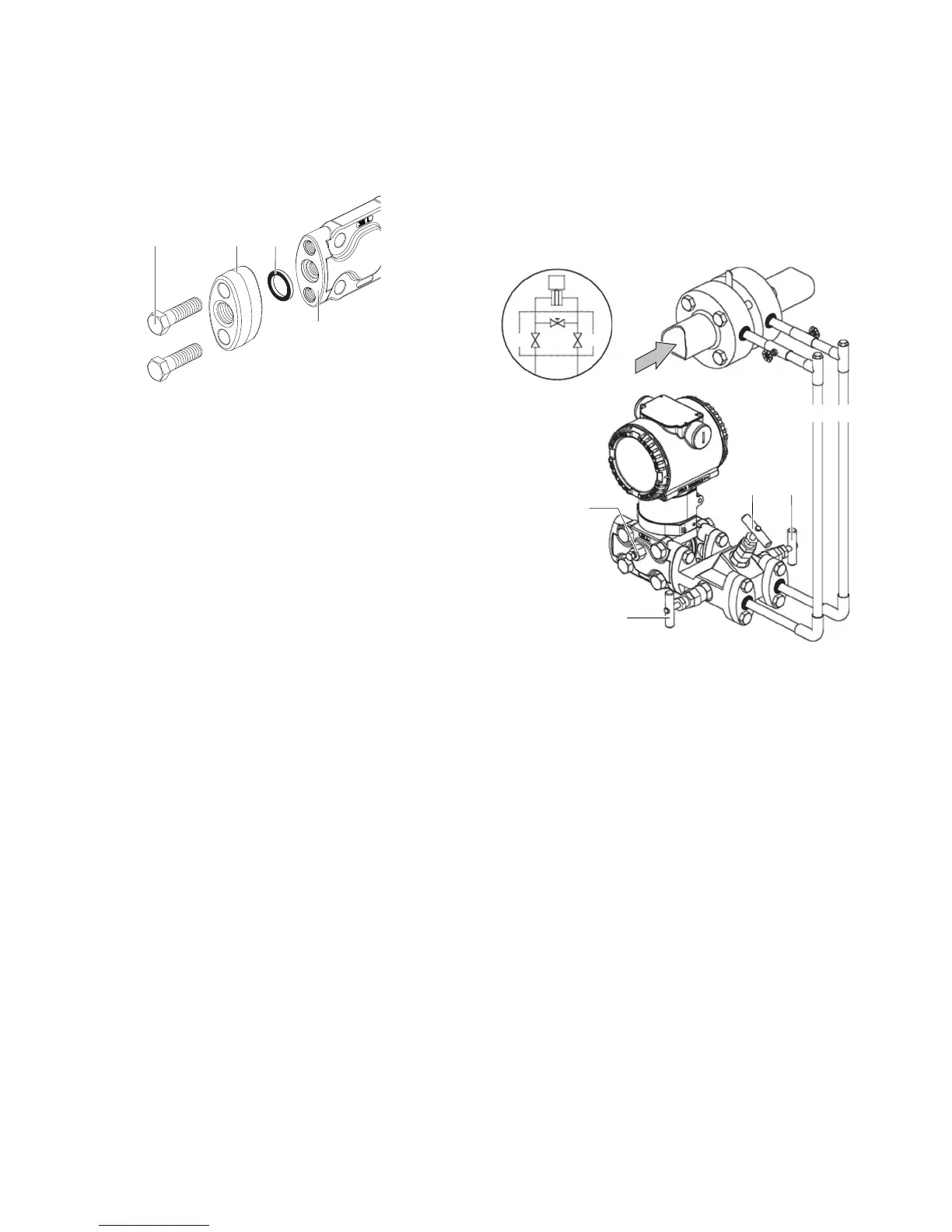

M10801-01

1 2 3

4

1 Screws

2 Flange adapter

3 O-ring

4 Transmitter connection flange

Figure 17: Process connection

On the flange of the 266 multivariable transmitter there are

¼ to 18 NPT process connections with middle point spacings of

54 mm (2.13 in). The process connections on the flange enable

direct attachment of 3 elements or 5 element valve manifolds.

Optionally flange adapters with ½ to 14 NPT connections are

available. By turning one or both adapters, middle point spacing

of 51 mm (2.01 in), 54 mm (2.13 in) or 57 mm (2.24 in) is possible.

Mount the adapters as follows:

1. Correctly position the adapters with inserted O-ring.

2. Screw the adapters on the transmitter connection flange

with the provided screws.

Tighten the screws as follows: Preliminary tightening

hand tight, preliminary tightening with 10 Nm, final

tightening with 50 Nm.

Mounting recommendations

The arrangement of the impulse lines depends on the respective

measurement application.

Flow measurement of steam (condensible vapor) or clean

liquids

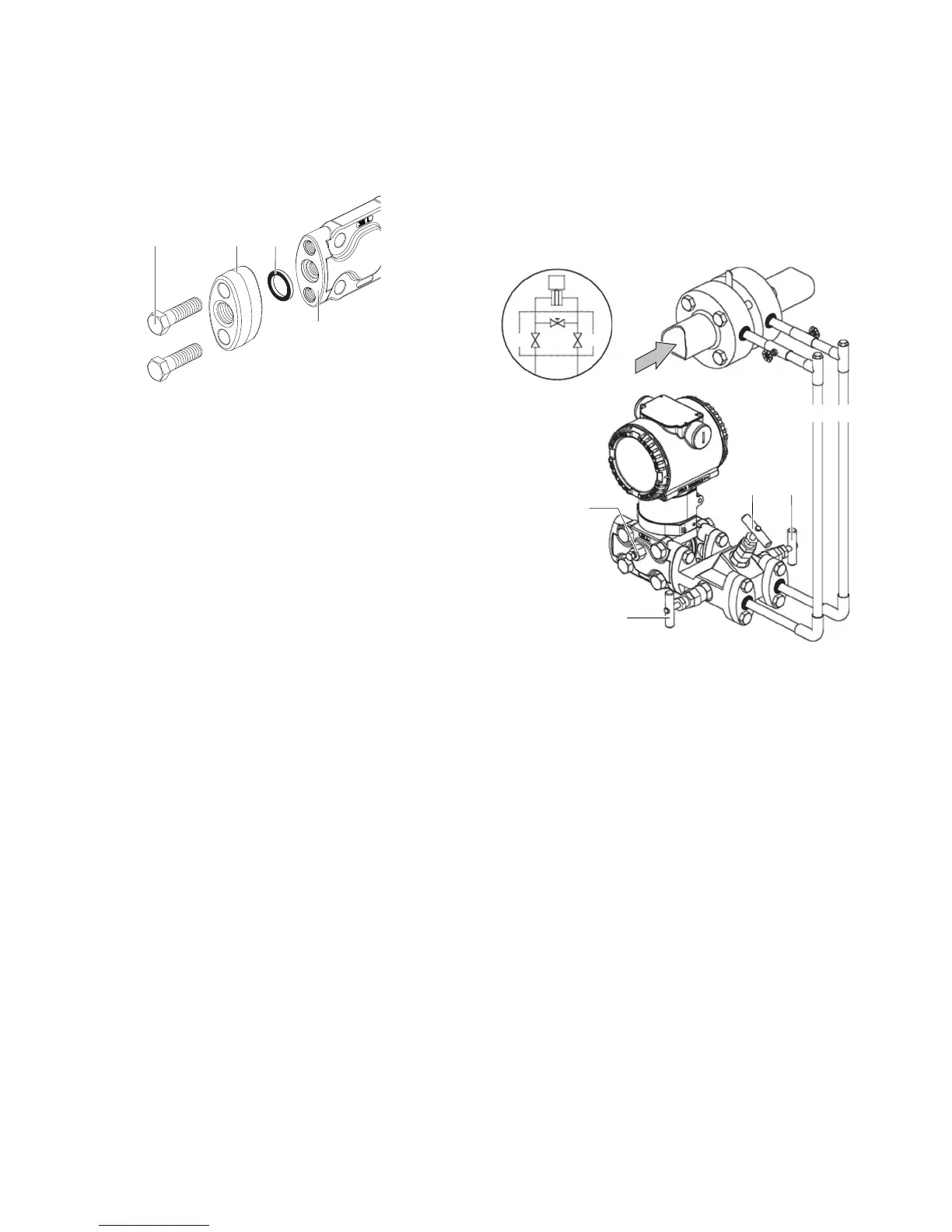

M10763-01

4

1

3 2

H L

H L

1 2

3

H High pressure side

L Low pressure side

1 High-pressure valve

2 Low pressure valve

3 Equalizing valve

4 Vent / Drain valve

Figure 18: Steam flow measurement

• Place taps to the side of the process line.

• For liquid measurements, mount the transmitter next to or

underneath the taps, for steam measurements underneath

the taps.

• Mount the vent / drain valve pointing upward.

• For steam applications, fill the vertical section of the impulse

lines with a compatible fluid through the appropriate filling

connections.

The height of the liquid column between process line and

transmitter must be the same on the high pressure side and the

low pressure side, so that an accurate measurement is ensured.

For implementation of this requirement it can be practical for

steam measurements, to use the impulse lines condensate

tanks.

Loading...

Loading...