PCP/ESP program features 45

Timing diagram

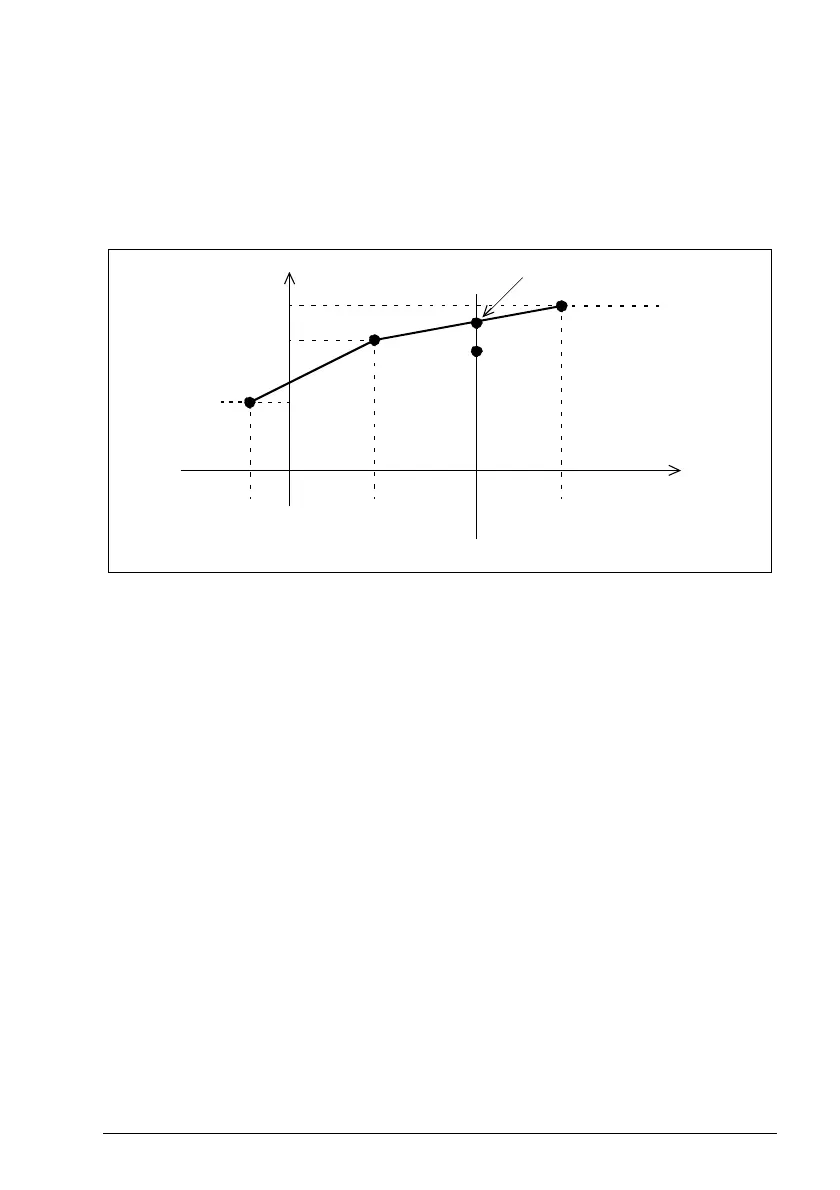

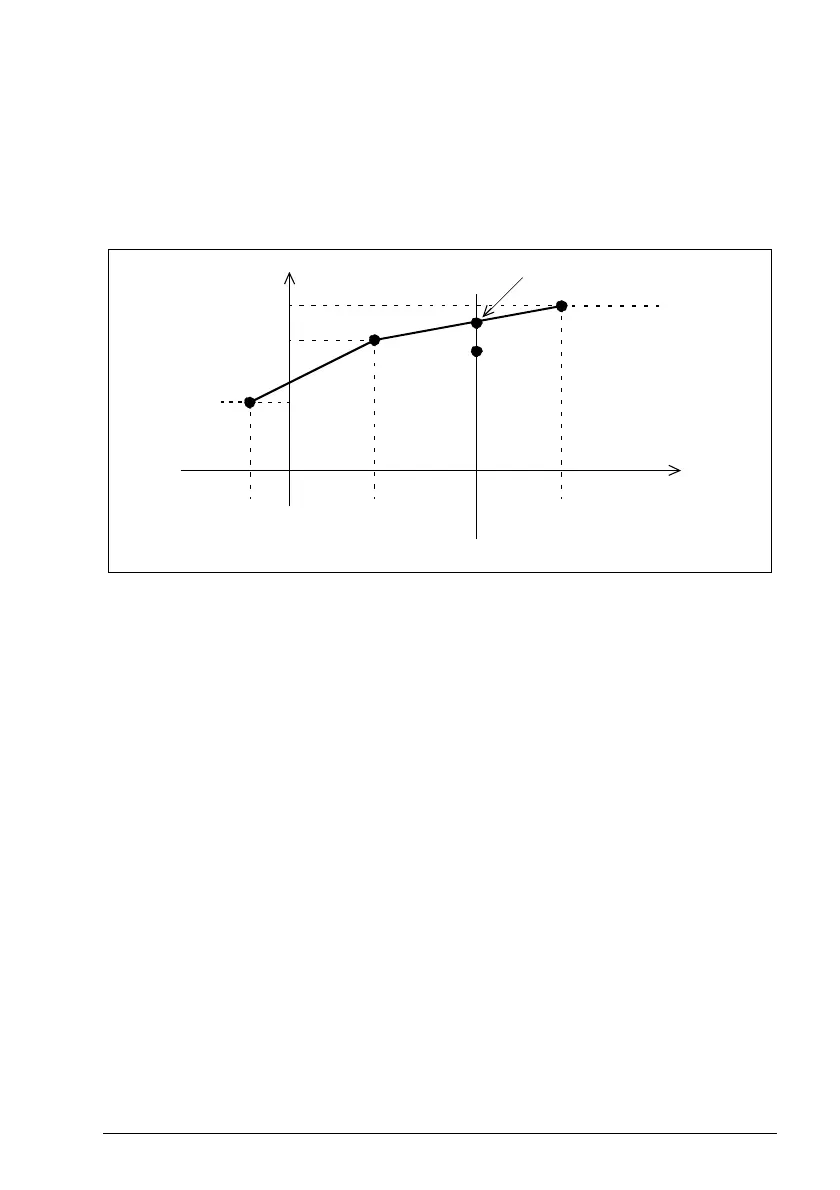

The points (X1, Y1), (X2, Y2) and (X3, Y3) on the user defined monitoring curve are

taken as reference to calculate the underload condition. The actual rod torque is

compared with the interpolated points on the curve. If the value lies below the curve,

it is interpreted as underload condition.The pump underload protection function is

active after the delay time is passed.

Settings

Parameter group: 78 Pump underload protection

Signals: 09.01 Rod torque, 09.05 Rod speed and 09.14 Pump status word (Bit 6).

Warnings: D202 Underload

Faults: D102 Underload fault

Pump temperature protection

This function protects the pump from overheating. User can select the reaction on

overheating condition: Warning, Fault or no reaction. The temperature feedback

comes through analog input (PT-100) or digital input (Klixon), or both the sources can

be connected and used simultaneously. The pump temperature protection function

provides temperature data through analog sensor even if temperature protection is

disabled.

Timing diagram

The measured temperature is compared against the defined fault and warning

temperature limits. When the measured value reaches the warning limit, the

temperature protection function is activated. After the delay time in 5 seconds, a

warning message is triggered. The temperature protection function is still active. After

Y3 (Par 78.07)

Y2 (Par 78.05)

X1

(Par 78.04)

X2

(Par 78.06)

X3

(Par78.08)

Rod torque

Rod speed

Actual rod speed

Actual rod torque (Underload)

Calculated rod torque

Normal region

Underload region

Y1 (Par 78.03)

Loading...

Loading...