ADTECH9 Series CNC Maintenance Manual

- 154 -

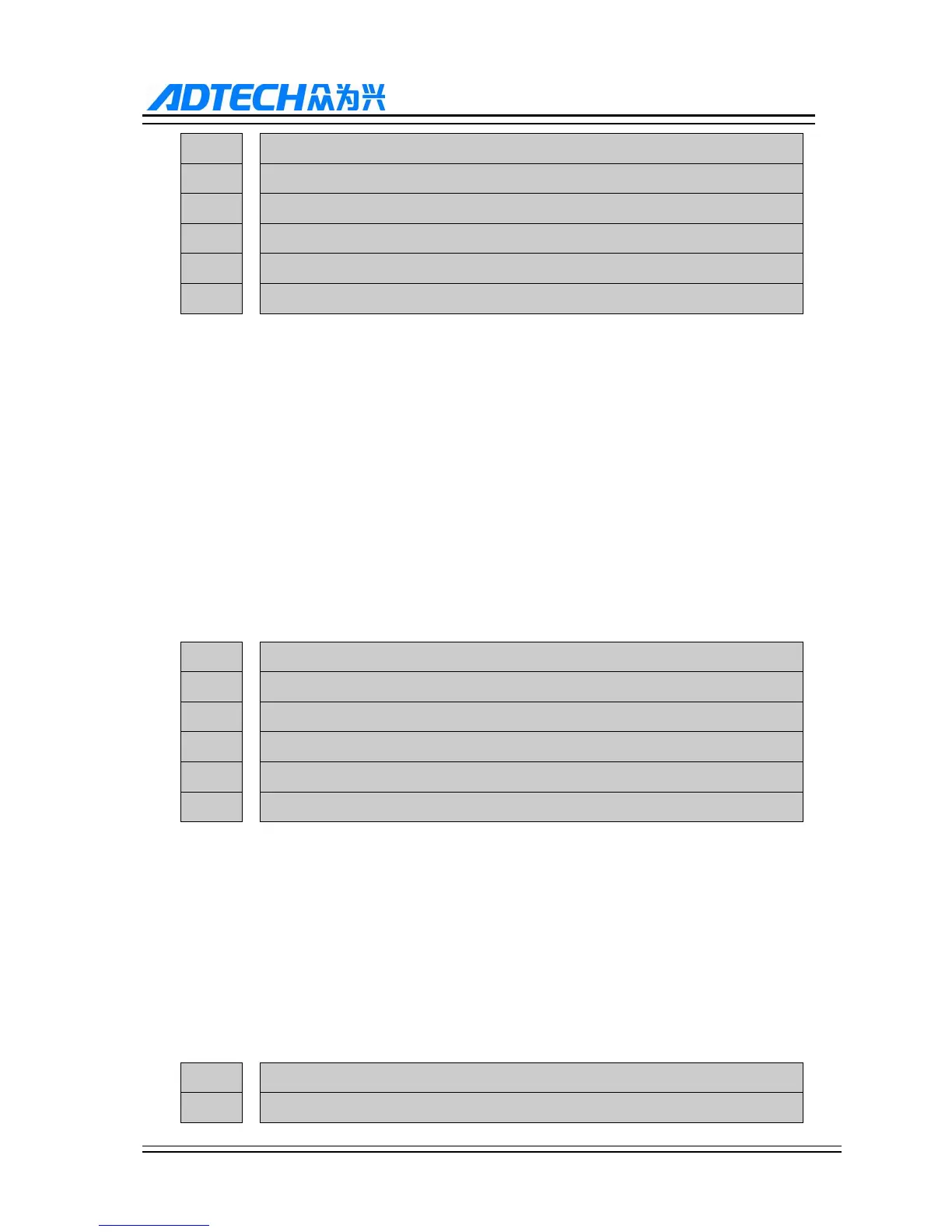

046 X-axis single-turn offset (mm/turn)

Y-axis single-turn offset (mm/turn)

Z-axis single-turn offset (mm/turn)

A-axis single-turn offset (mm/turn)

B-axis single-turn offset (mm/turn)

C-axis single-turn offset (mm/turn)

Range : -9999.999 ~ 9999.999

Unit :

Authority : Super Admin

Default : 0

Effective time : Instant

Note : It is used to set the screw moving distance after servo rotates a turn

(usually be used by the absolute servo motor or ETherCAT bus servo in

setting movement per revolution. Note: After setting this parameter for

bus controller, it is not necessary to set P2 parameter 001 multiplication

ratio and frequency division coefficient)

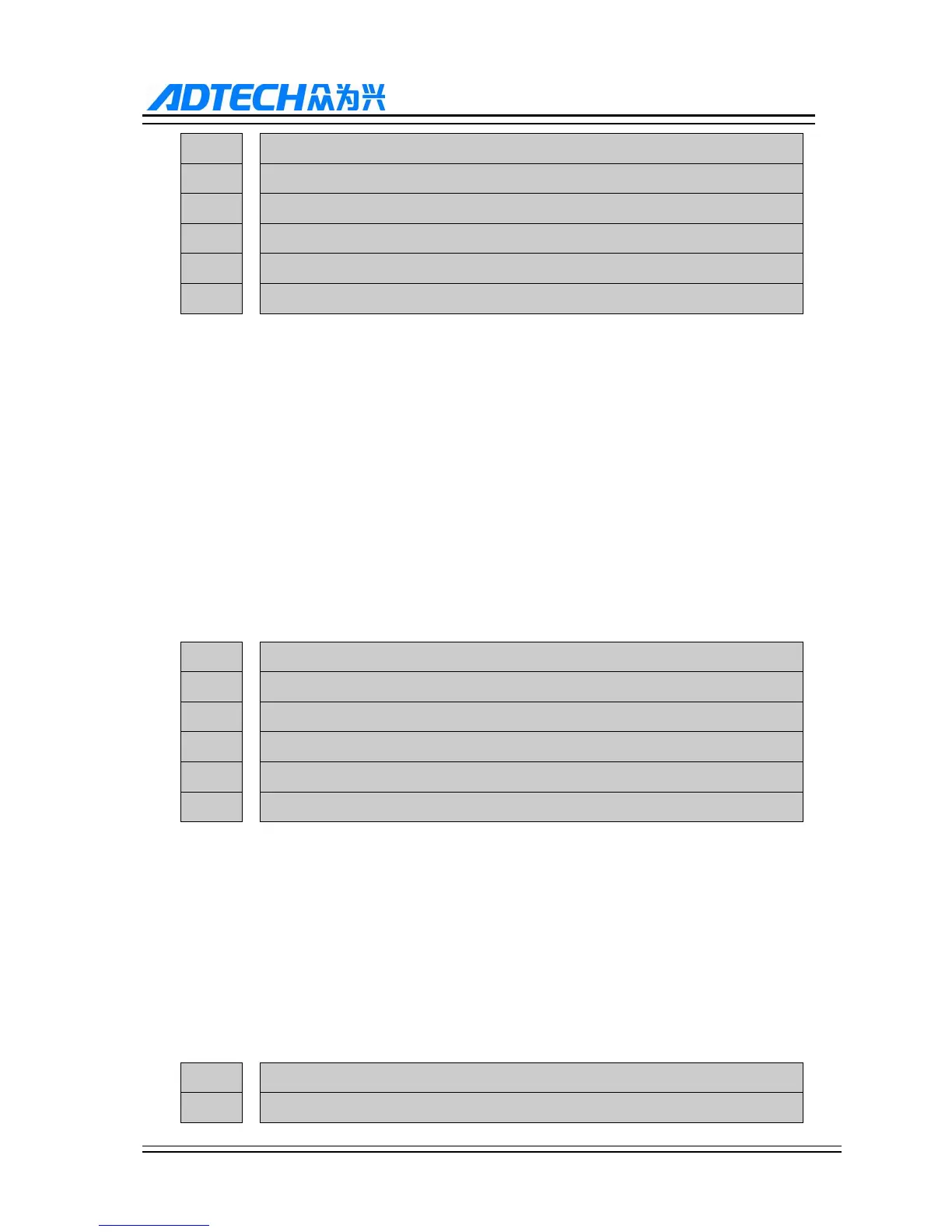

047 X-axis absolute encoder origin calibration

Y-axis absolute encoder origin calibration

Z-axis absolute encoder origin calibration

A-axis absolute encoder origin calibration

B-axis absolute encoder origin calibration

C-axis absolute encoder origin calibration

Range : -9999.999 ~ 9999.999

Unit :

Authority : Super Admin

Default : 0

Effective time : Instant

Note : To set the absolute encoder servo origin position calibration for the

ETherCAT bus

048 X Servo Driver Type

Y Servo Driver Type

Loading...

Loading...