21

IHBI. 1011. 4138500_00

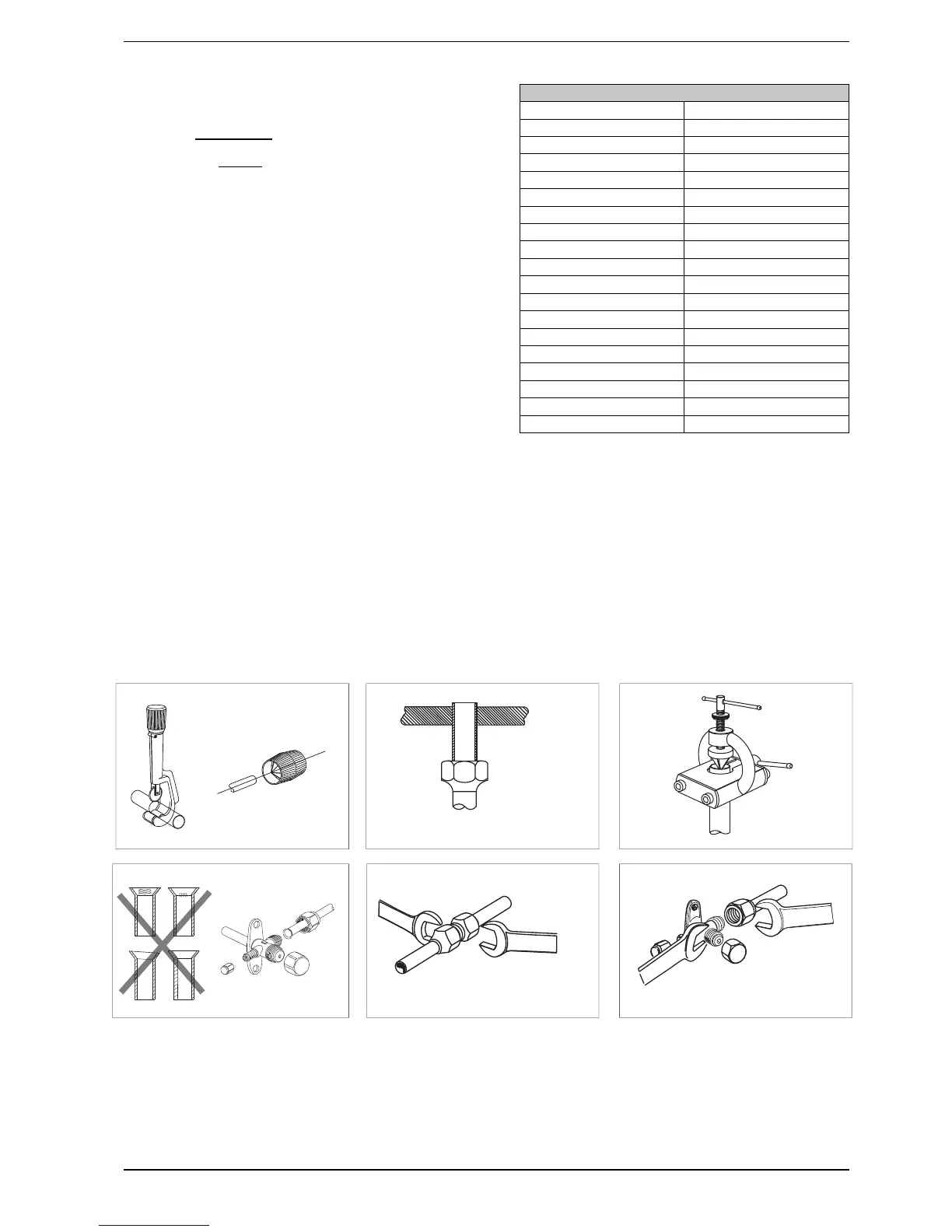

WATER EXPANSION FACTOR AT DIFFERENT TEMPERATURES

Temperature (°C) Expansion factor (e)

0 0.00013

40

10 0.00027

20 0.00177

30 0.00435

40 0.00782

45 0.0099

50 0.0121

55 0.0145

60 0.0171

65 0.0198

70 0.0227

75 0.0258

80 0.029

85 0.0324

90 0.0359

95 0.0396

100 0.0434

SELECTING THE EXPANSION VESSEL:

Formula:

V = Volume of the expansion vessel

c = Total volume of the water

p

1

= Expansion vessel pre-load pressure

p

2

= Maximum pressure during system functioning

(i.e. safety valve activation pressure).

e = Water expansion factor (the differnce between

the original water temperature expansion factor

and that of the highest water temperature).

V =

c

.

e

1-

1+p

1

1+p

2

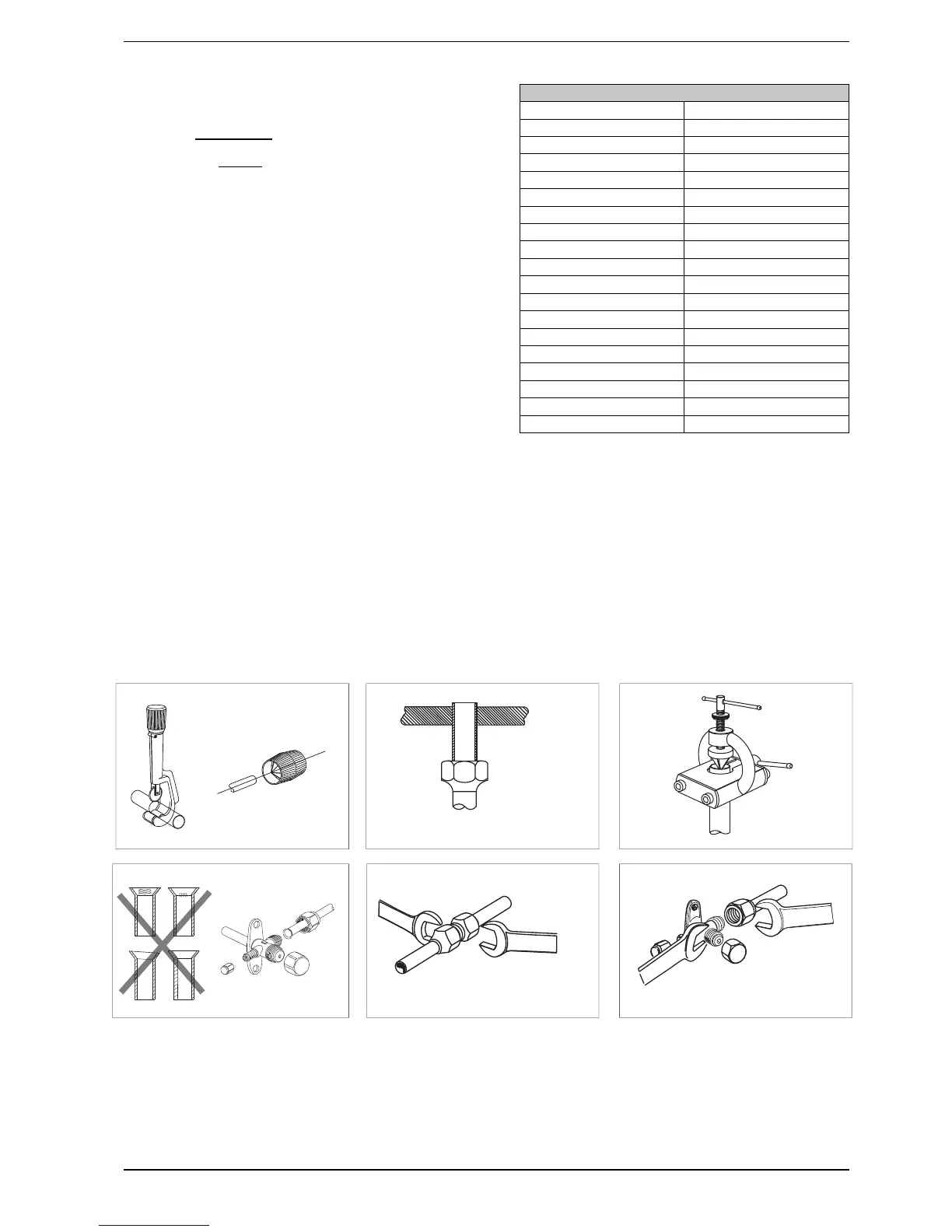

16. PROCEDURES FOR THE REALISATION OF THE COOLING LINES

Procedure for the preparation of the fl ared fi t-

tings:

The cooling lines and the HBI unit are real-

ised using fl ared connections

Flared connections: used in the tracts

connected directly to the refrigerant con-

nections (gas and liquid lines) of the out-

door or indoor units;

The procedure for the realisation of a

fl ared connection is as follows:

• cut the copper pipes to measure-

ment using the pipe-cutter and

smooth the ends using a pipe debur-

rer (Fig. A);

• isolate the pipes and insert the ta-

pered nuts before fl aring (Fig. B);

• for fl aring use a tapered fl aring tool

(Fig. C);

• check that the tapered surface is in

axis with the pipe, smooth, without

cracks and even thickness (Fig. D).

• connect the lines with the fl ared con-

nections

Fig. C

Fig. E

Fig. A Fig. B

Fig. D

Fig. F

Loading...

Loading...