39

IHBI. 1011. 4138500_00

Inspection

The inspection checks that the unit can function normally via pre-functioning. If the unit cannot function normally, fi nd and solve the

design problem or of the unit until the inspection is satisfi ed. Every inspection must respect the requisites before execution of the inspec-

tion. The inspection must follow the content and the phases of the table stated below:

THE FOLLOWING PROCEDURE MUST BE PERFORMED BY EXPERT, QUALIFIED STAFF.

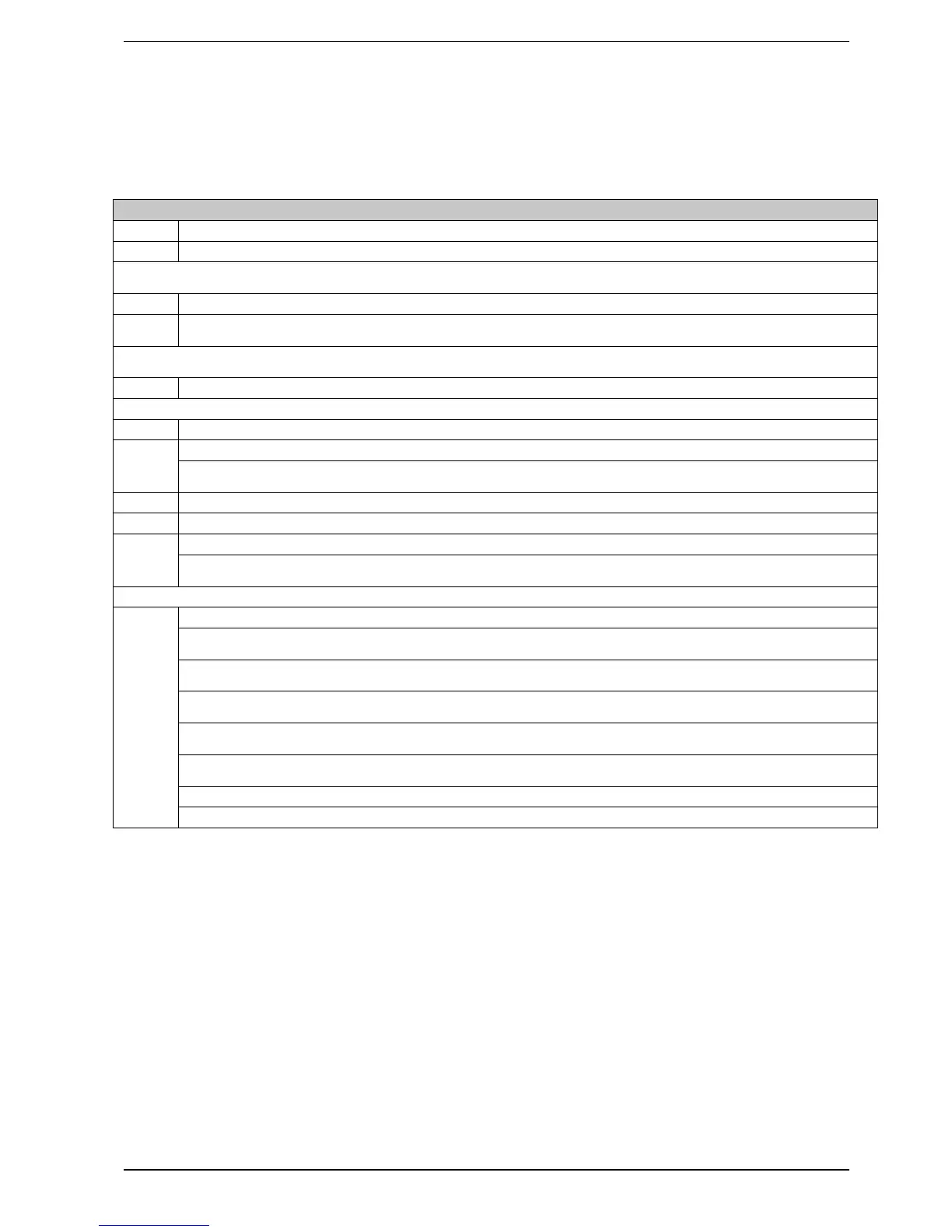

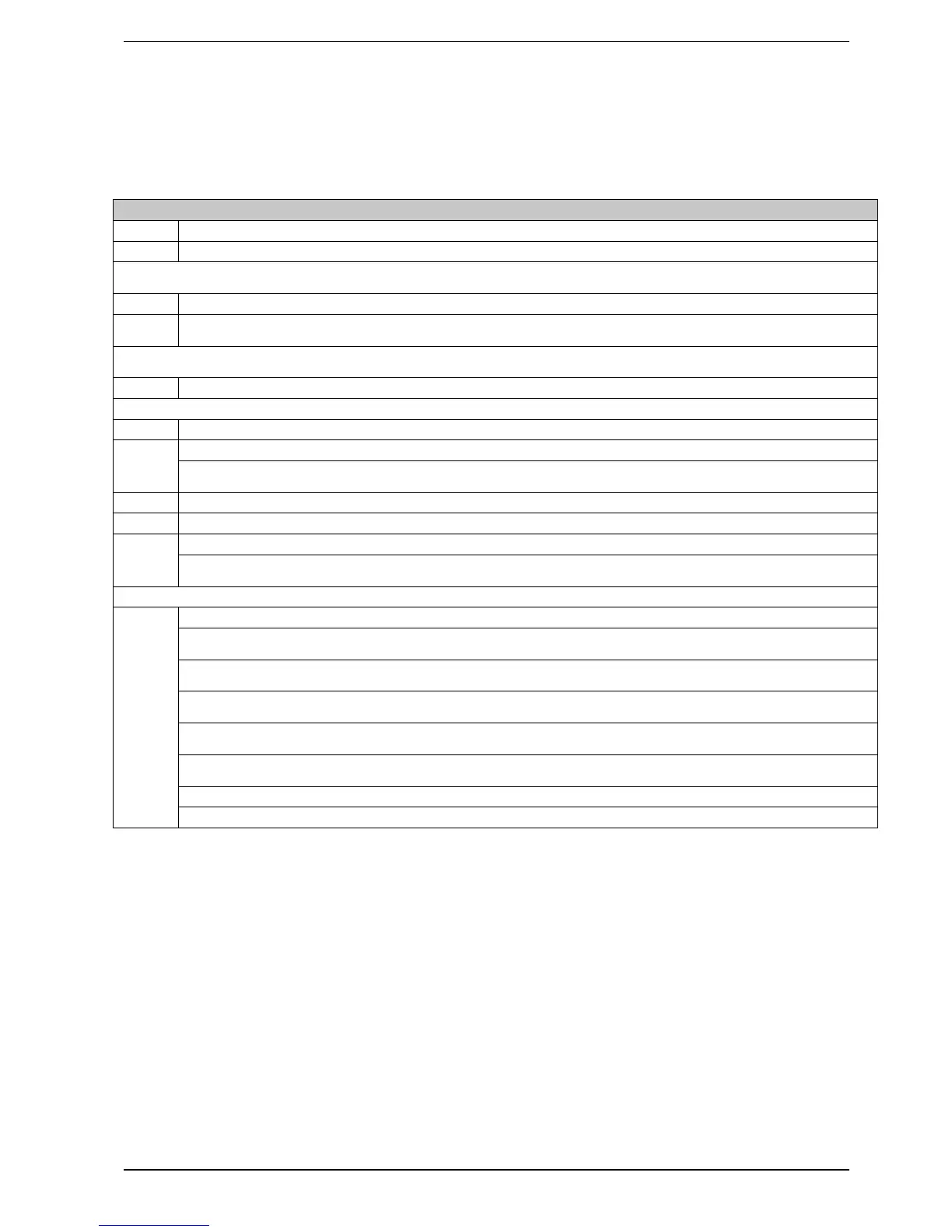

N. Start the pre-test procedure

1 Make sure that the unit compressor is pre-heated for 8 hours.

Attention: heat the lubricant oil 8 hours in advance in order to prevent the refrigerant mixing with the lubricant oil and causing dam-

age to the compressor on unit start-up.

2 Check whether the temperature of the compressor oil is higher than the external outdoor temperature.

3

Check whether the sequence of the main power supply phases is correct. Otherwise, correct the sequence on the basis

of the specification.

Re-control the sequence of the phases before start-up to prevent the inversion of the compressor with consequent damage to the

unit.

4

Applicare il metro elettrico universale per misurare la resistenza di isolamento tra ciascuna fase esterna e tra le fasi.

Attention: A faulty earth connection can cause electric shocks.

N. Ready for start-up

1

Cut the electric power supply off, restore all protections and control the electricity for the last time.

Verificare l’alimentazione e la tensione del circuito di controllo; _V deve essere ±10% nel range di potenza operativa

nominale.

N. Start the unit

1 Check all of the conditions necessary for unit start-up: temperature of the oil, mode, requested load etc.

2

Start the unit and observe compressor func. electric expansion valve, fan motor, water pump etc.

NB: the unit will be damaged if functioning in an anomalous way. Do not activate the unit in the event of high pressure and

high current.

Additional information:

Items for

accept-

ance

after the

debug

Evaluation or suggestions regarding the general functioning situation: good, modify

Identify the potential problem (if nothing is written it means that the installation and debug are in compliance with requi-

sites).

a. power supply and electric control system problem

b. load calculation problem

c. external refrigerant system

d. problem with noise

e. indoor piping and indoor system problem

h. other problems

Loading is necessary during functioning in order to perform maintenance due to problems of low quality, such as installa-

tion and improper maintenance.

Situation for acceptance:

Is the user trained on the basis of the specifications? Sign. Yes ( ) No ( )

Loading...

Loading...