Site Preparation

Cryogenic cooling requirements

18

Table 7. Recommended Traps

Moisture in carrier gas damages columns. We recommend a type 5A Molecular

Sieve trap after the source regulator and before any other traps.

A hydrocarbon trap removes organics from gases. It should be placed after a

molecular sieve trap and before an oxygen trap, if they are present.

An oxygen trap removes 99% of the oxygen from a gas plus traces of water. It

should be last in a series of traps. Because trace amounts of oxygen can damage

columns and degrade ECD performance, use an oxygen trap with carrier and

ECD gases. Do not use it with FID, FPD, or NPD fuel gases.

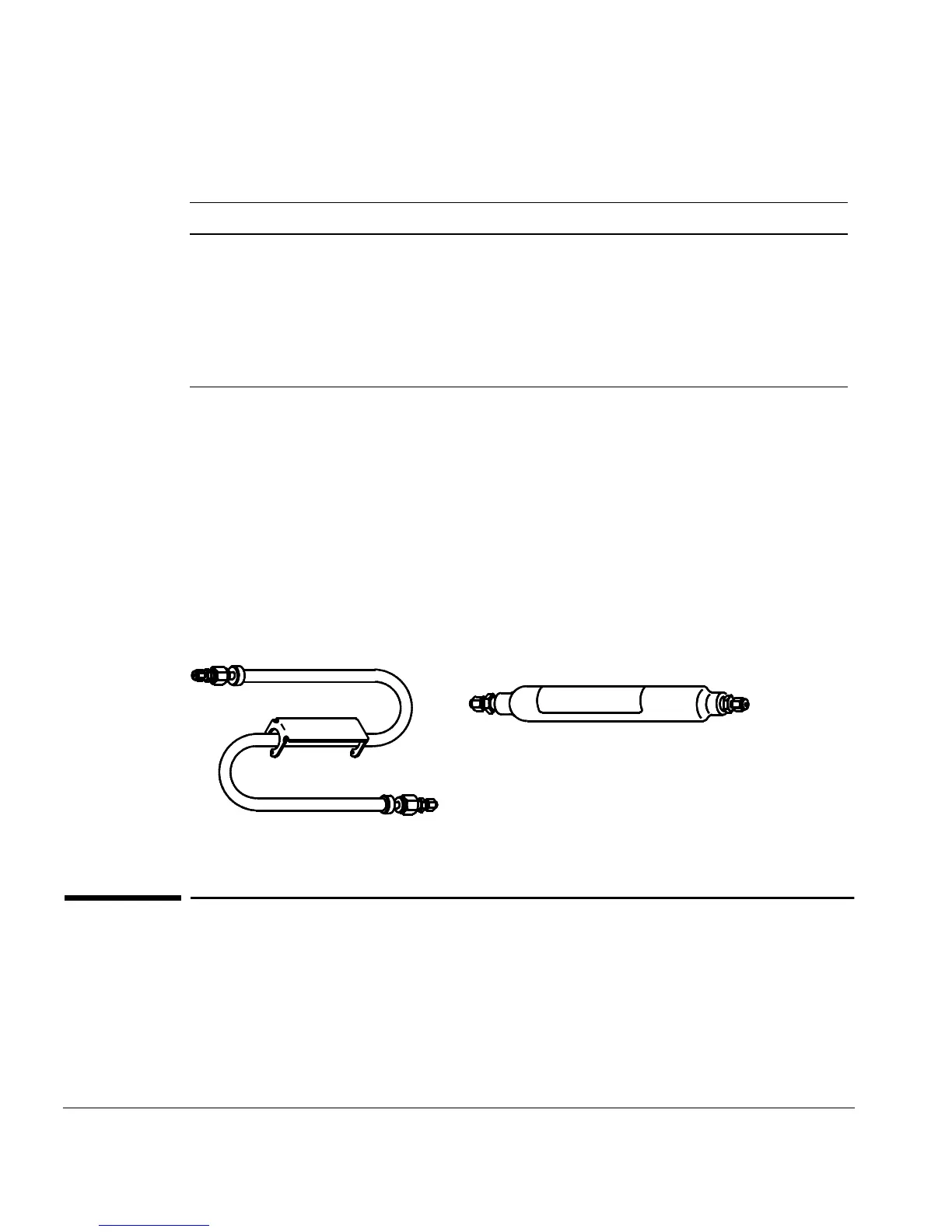

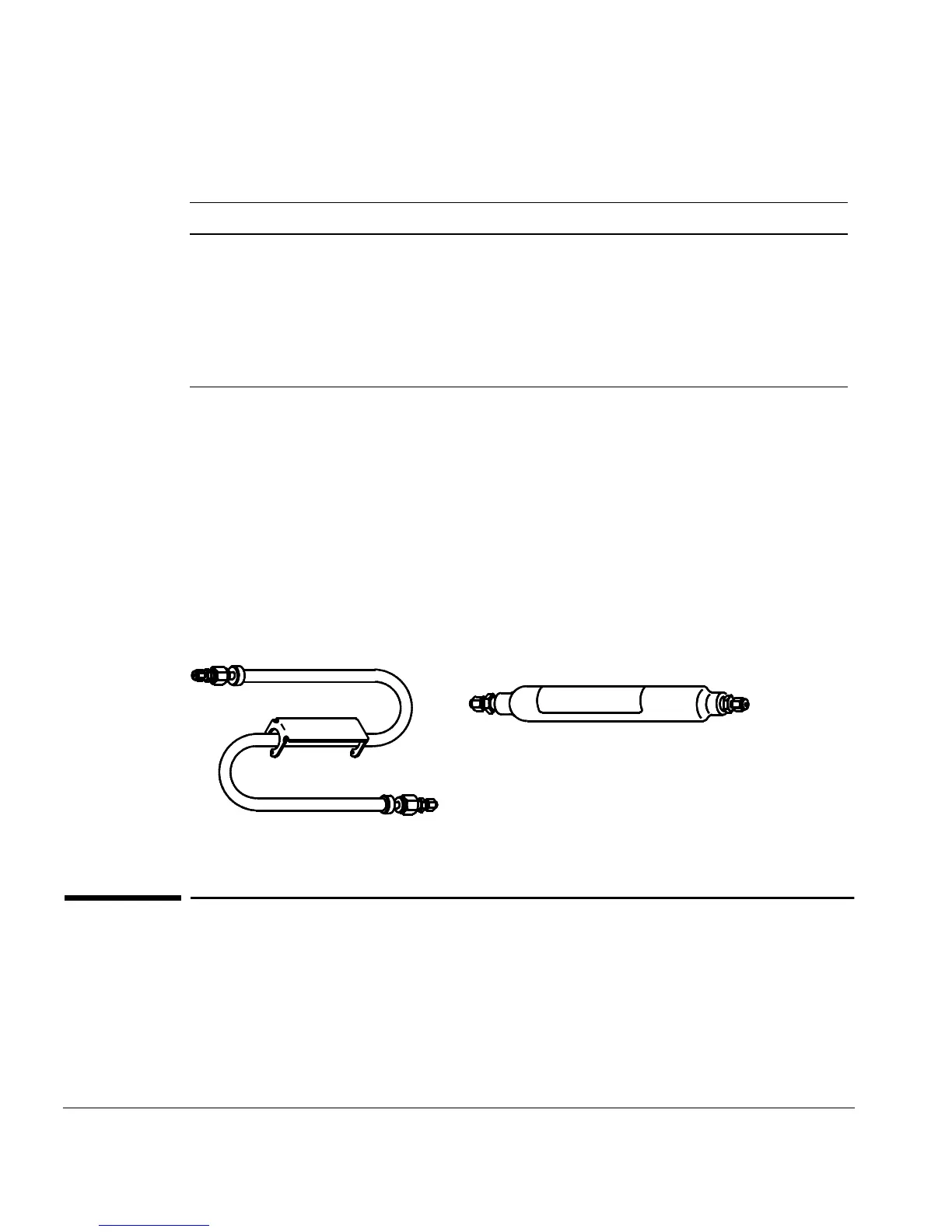

Figure 4. Traps

Cryogenic cooling requirements

Cryogenic cooling allows you to cool the oven below ambient temperature. A

solenoid valve introduces liquid coolant, either carbon dioxide (CO

2

) or nitrogen

(N

2

), to cool the oven to the desired temperature.

Description Part no.

Preconditioned moisture trap: metal casing, s-shaped trap for carrier gas cleanup.

Contains Molecular Sieve 5A, 45/60 mesh, and 1/8-inch fittings.

5060-9084

Hydrocarbon trap: metal casing, s-shaped trap filled with 40/60 mesh activated

charcoal, and 1/8-inch fittings

5060-9096

Oxygen trap (for carrier and ECD gases): metal casing, and 1/8-inch brass fittings.

Oxygen trap cannot be reconditioned.

3150-0414

Molecular sieve or hydrocarbon trap—both are S-shaped

Oxygen trap

Loading...

Loading...