Site Preparation

Cryogenic cooling requirements

20

These contaminants could clog the expansion orifice or affect the proper

operation of the GC.

Additional requirements for the liquid CO

2

system include:

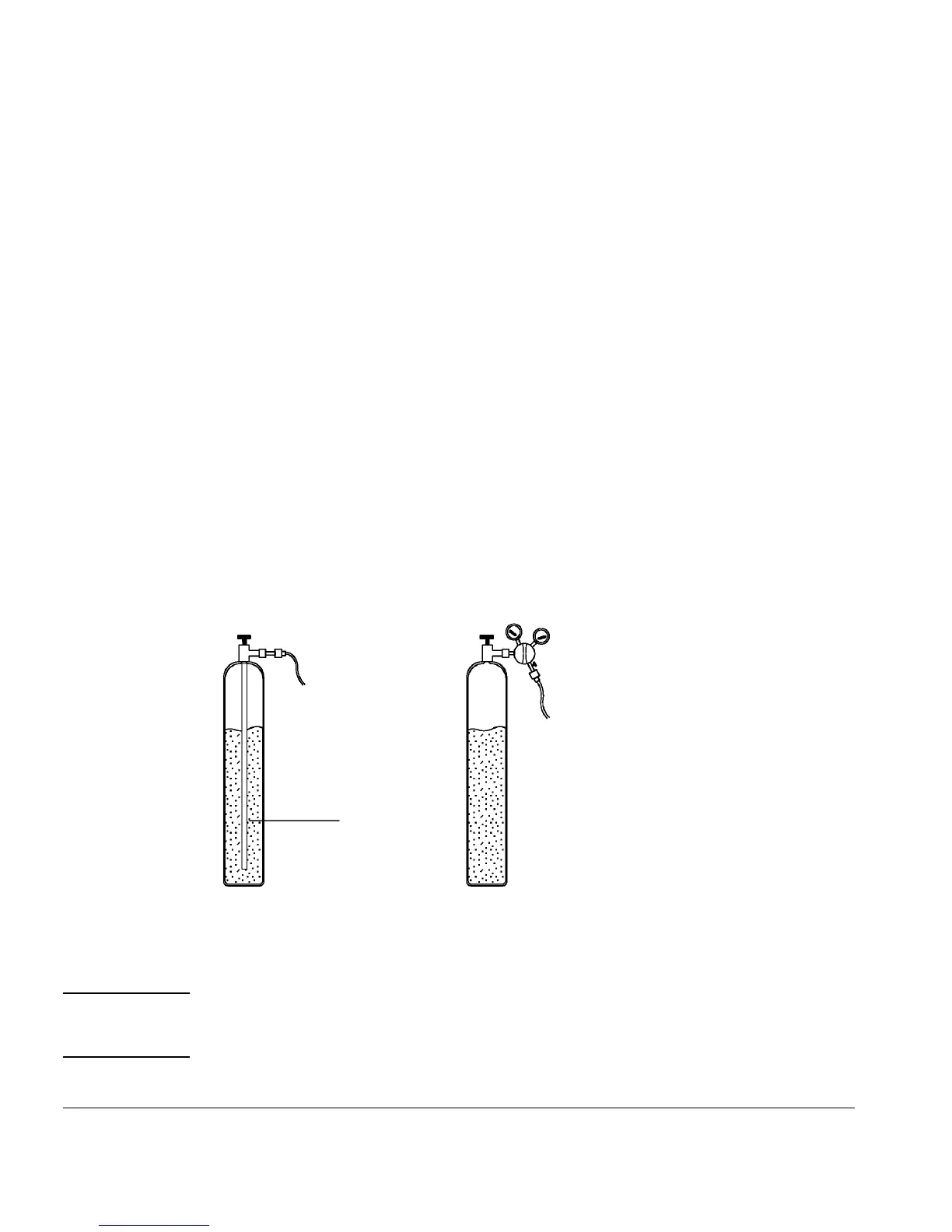

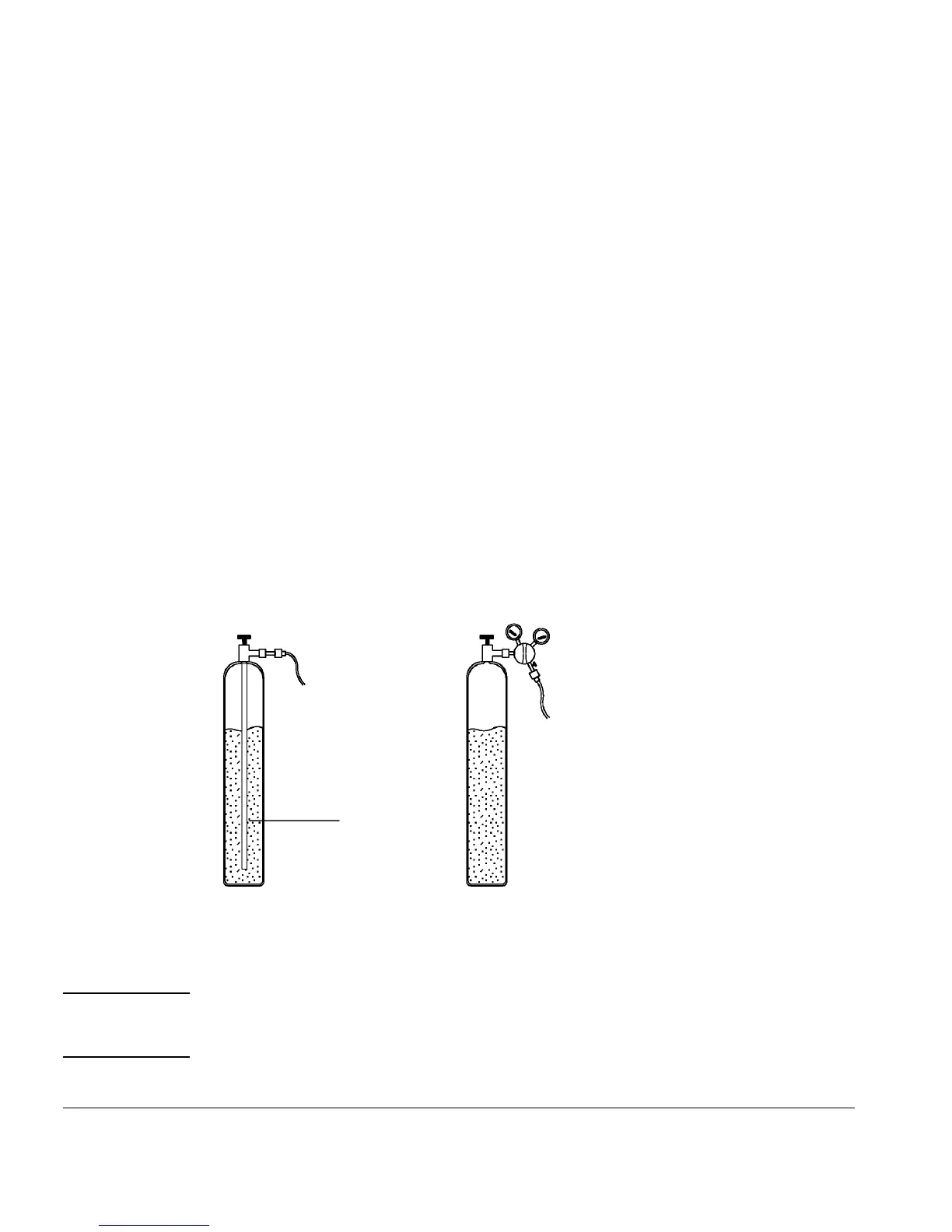

• The tank must have an internal dip tube or eductor tube to deliver liquid CO

2

instead of gas (see Figure 5).

• The liquid CO

2

must be provided to the GC at a pressure of 700 to 1,000 psi

at a temperature of 25°C.

• Use 1/8-inch diameter heavy-wall stainless steel tubing for supply tubing. The

tubing should be between 5 to 50 feet long.

• Coil and fasten the ends of the tubing to prevent it from “whipping” if it

breaks.

• Do not install a pressure regulator on the CO

2

tank, as vaporization and

cooling would occur in the regulator instead of the oven.

• Do not use a padded tank (one to which another gas is added to increase the

pressure).

Figure 5. Correct and incorrect liquid CO

2

tank configuration

WARNING Do not use copper tubing or thin-wall stainless steel tubing with liquid CO

2

. Both

harden at stress points and may explode.

Dip tube

Correct configuration Incorrect configuration

Loading...

Loading...