Option 100 Fault Location and SRL 1-15

Introduction and Measurement Theory

Cable Impedance and Structural Return Loss Measurement Theory

The default values for the connector model are 0.00 mm length, and

0.00 pF capacitance (no compensation).

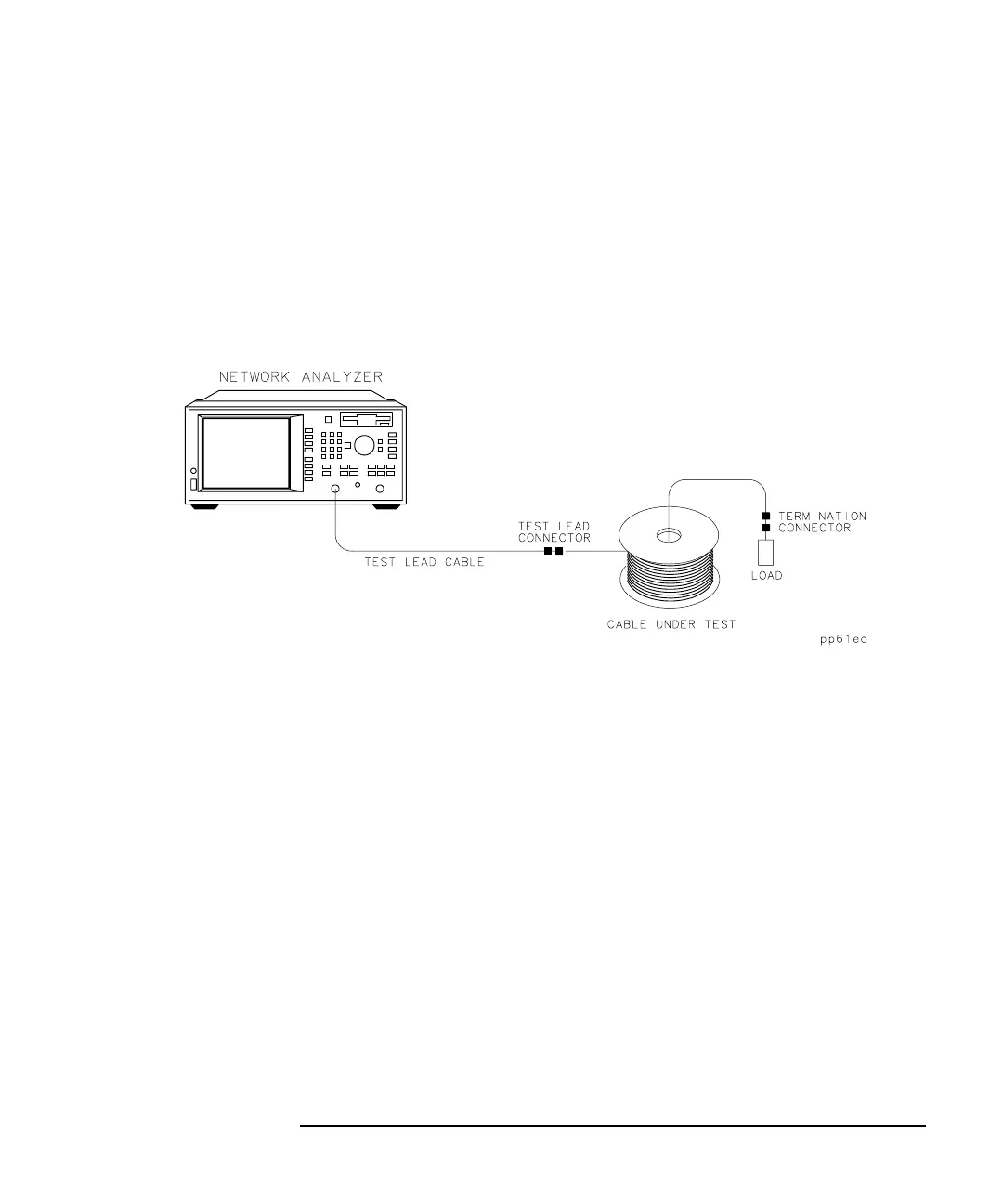

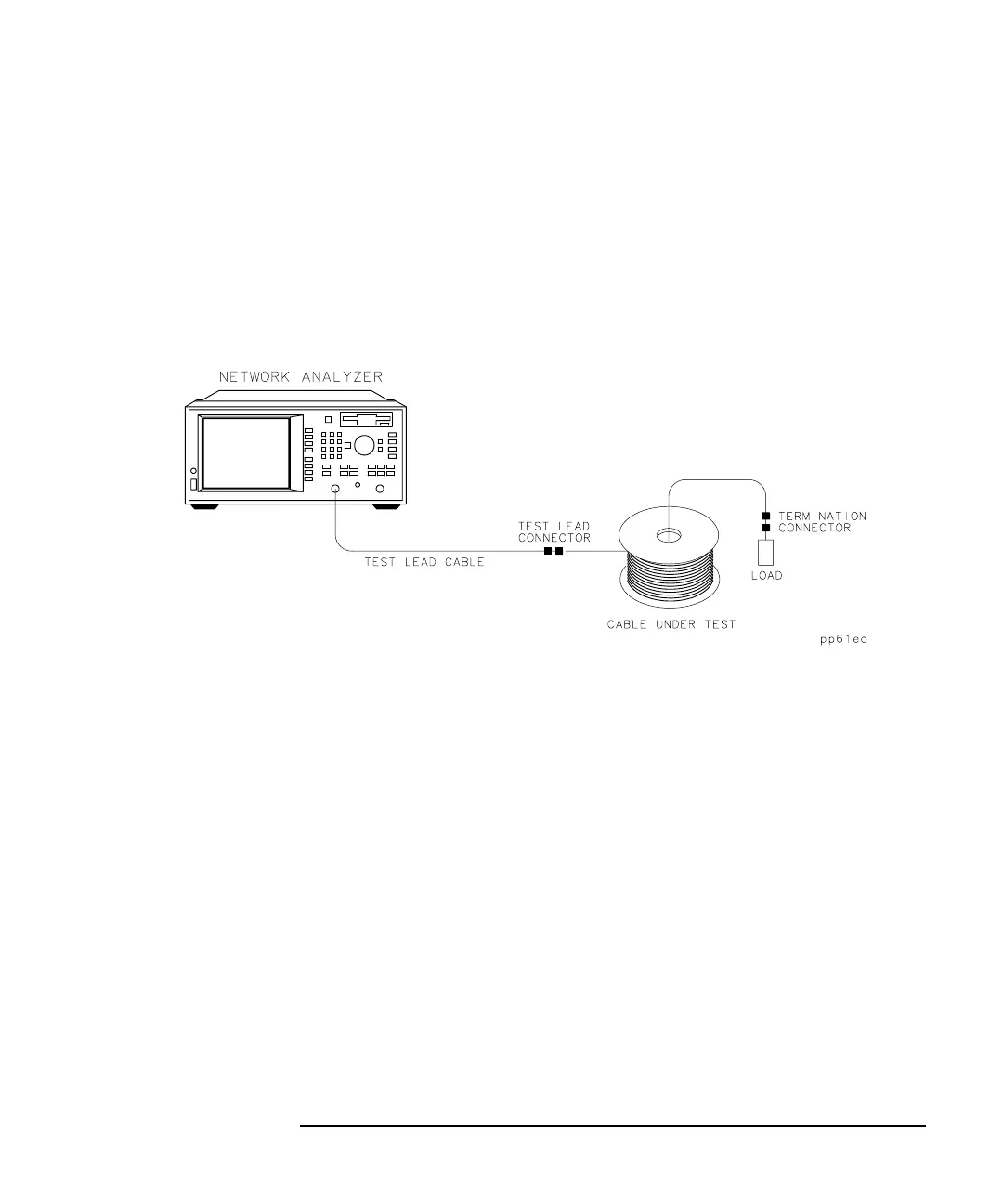

When measuring spools of cable, typically two connectors are used: the

test-lead connector and the termination connector. (See Figure 1-3.)

These connectors provide the cable interface and are measured as part of

the cable data.

Figure 1-3 Basic SRL Measurement Setup and Connections

Often, slight changes in the test-lead connector can cause significant

changes in the values of structural return loss measured at high

frequencies. This is because the reflection from a connector increases for

high frequencies. In fact, the return loss of a test-lead connector can

dominate the SRL response at frequencies above 500 MHz. This is where

training, good measurement practices, and precision cable connectors are

needed, especially for measurements up to 1 GHz. Precision connectors

are required to provide repeatability over multiple connections. Slip-on

connectors are used to provide rapid connections to the cables, but

require careful attention in obtaining good measurement data.

Repeatability of measurement data is directly affected by the connector's

ability to provide a consistently good connection. This is the major cause

of repeatability problems in SRL measurements.

Effects of the test-lead connector at the measurement interface are

observed as a slope in the noise floor at higher frequencies.

(See Figure 4-6 on page 4-11.) By observing the SRL measurement

display and slightly moving the connector, the effects of the connection

can be observed at the higher frequencies. The test-lead connector should

be positioned to obtain the lowest possible signal level and the flattest

Loading...

Loading...