The pressure relief valve controls the maximum pressure of

the hydraulic circuit. Normally, this valve does not require any

adjustment, since it is calibrated at the factory before the

machine is delivered.

The pressure relief valve must be calibrated in the following

cases:

▪ in case of replacement of the hydraulic block

▪ In case of replacement of the pressure relief valve only

Check operation at least once a year.

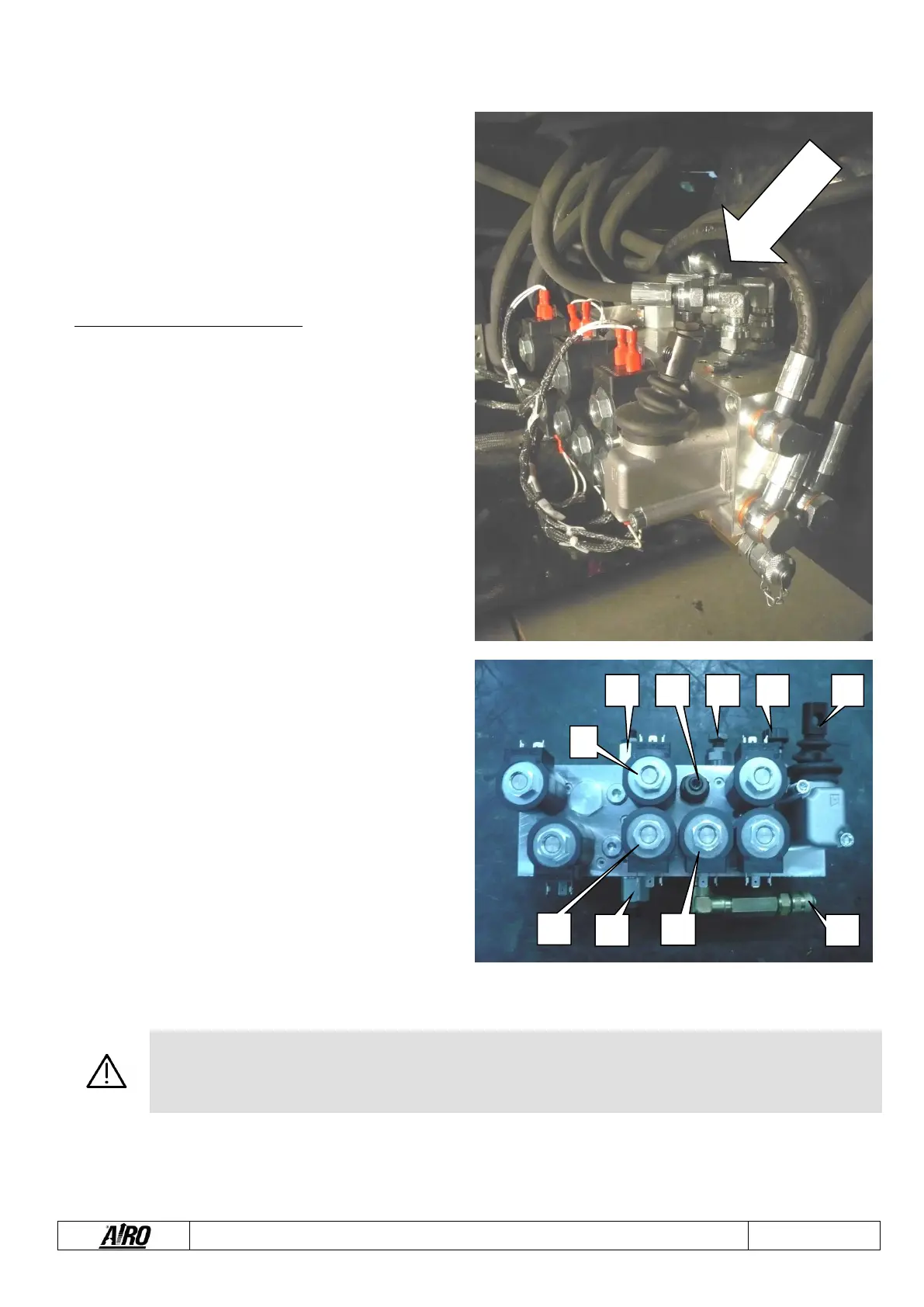

To check the operation of the pressure relief valve (figura

7-8):

▪ Disconnect the power cords of the solenoid valves EV2

and EV3 (H and I).

▪ Introduce a pressure gauge with full scale of at least 250

bar in the special quick coupling (1/4” BSP) D.

▪ Using the platform control panel drive the machine

forward and backward. Initially carry out the operation

softly to check that the above mentioned valves have

been disconnected properly (the machine should not

move).

▪ Check the pressure value. The correct value is indicated

in the chapter “Technical features”.

To calibrate the pressure relief valve (figure 7-8):

▪ Disconnect the power cords of the solenoid valves EV2

and EV3 (H and I).

▪ Introduce a pressure gauge with full scale of at least 250

bar in the special quick coupling (1/4” BSP) D.

▪ Locate the pressure relief valve A.

▪ Unscrew the adjusting dowel lock-nut.

▪ Using the platform control panel, drive the machine

forward and backward and adjust the pressure relief valve

by means of the adjusting dowel so as to reach the

pressure value indicated in chapter "Technical

Features". Initially carry out the operation softly to check

that the above mentioned valves have been disconnected

properly (the machine should not move).

▪ Once calibration has been carried out, lock the adjusting

dowel by means of the lock-nut.

Loading...

Loading...