Single Wire Seal crimp instructions 28 (38)

Installation Manual T-Rx 1000/1500 FSK12 FSK12 Version: B4 Document-ID: 945814-000 Author: SH

14.1.4 Description

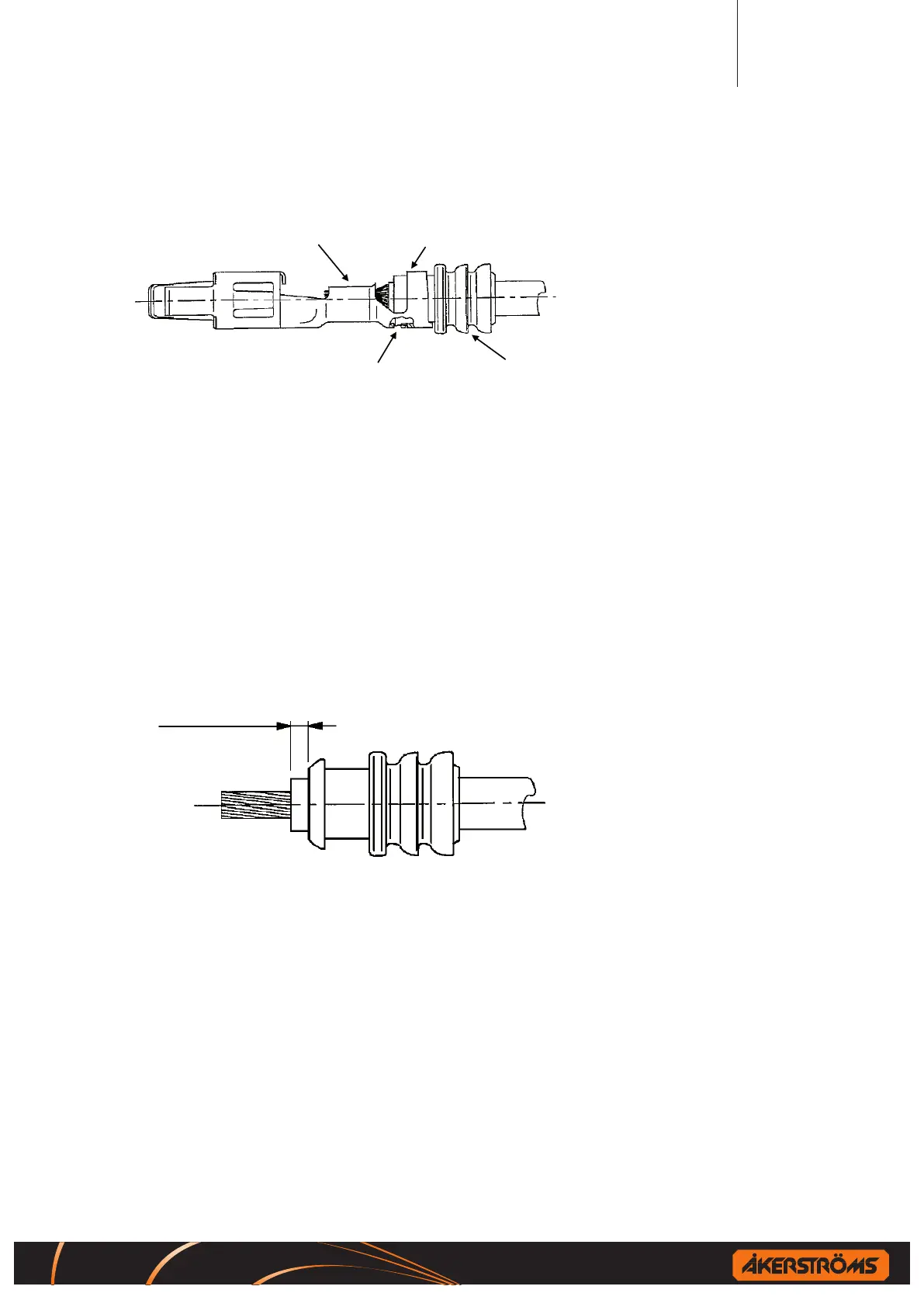

The terms shown below are used in this information.

Window

Insulation crimp

Wire crimp

Figure 12. Crimped contact

14.1.5 Preparation

14.1.5.1 Stripping

The wire must be stripped to the lengths shown in Figure 9. Take care that the individual strands

of the wire are not be bent or cut off. For single wire sealing, care must be taken that the insu-

lation of the wire in the sealing area is not damaged, compressed or deformed. The insulation

must be clean and free of contamination.

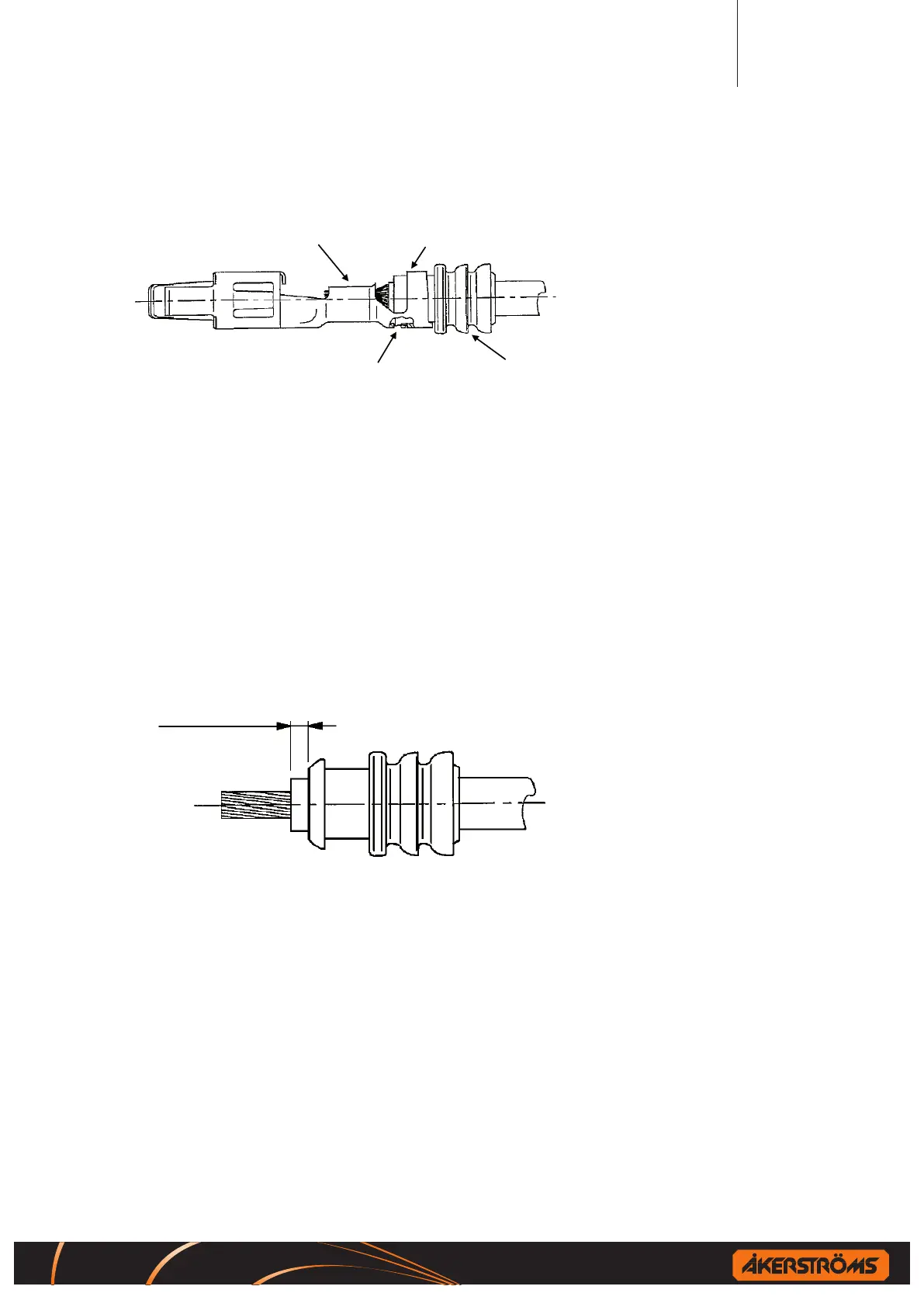

14.1.5.2 Position of the single-wire seal

The insulation end of the stripped wire must be ush with the front of the single wire seal or

may extend up to 1 mm. In no case may the single wire seal be crimped in the conductor crimp.

In the case of single-wire seals with a collar on the sleeve, this collar is positioned in front of the

front edge of the crimp.

max 1 mm

Figure 13. Single wire seal

14.1.6 Crimp requirements

14.1.6.1 Wire position

After crimping, the end of the wire must extend 0.1 ... 0.5 mm beyond the front end of the wire

crimp.

14.1.6.2 Position of the end of the insulation

The end of the insulation must be ush with the front edge of the single-wire seal or may project

by up to 0.5 mm from this seal. In no case may the insulation be crimped in the wire crimp.

Loading...

Loading...