216 Rockwell Automation Publication 1444-UM001D-EN-P - June 2018

Chapter 8 Configure Alarms

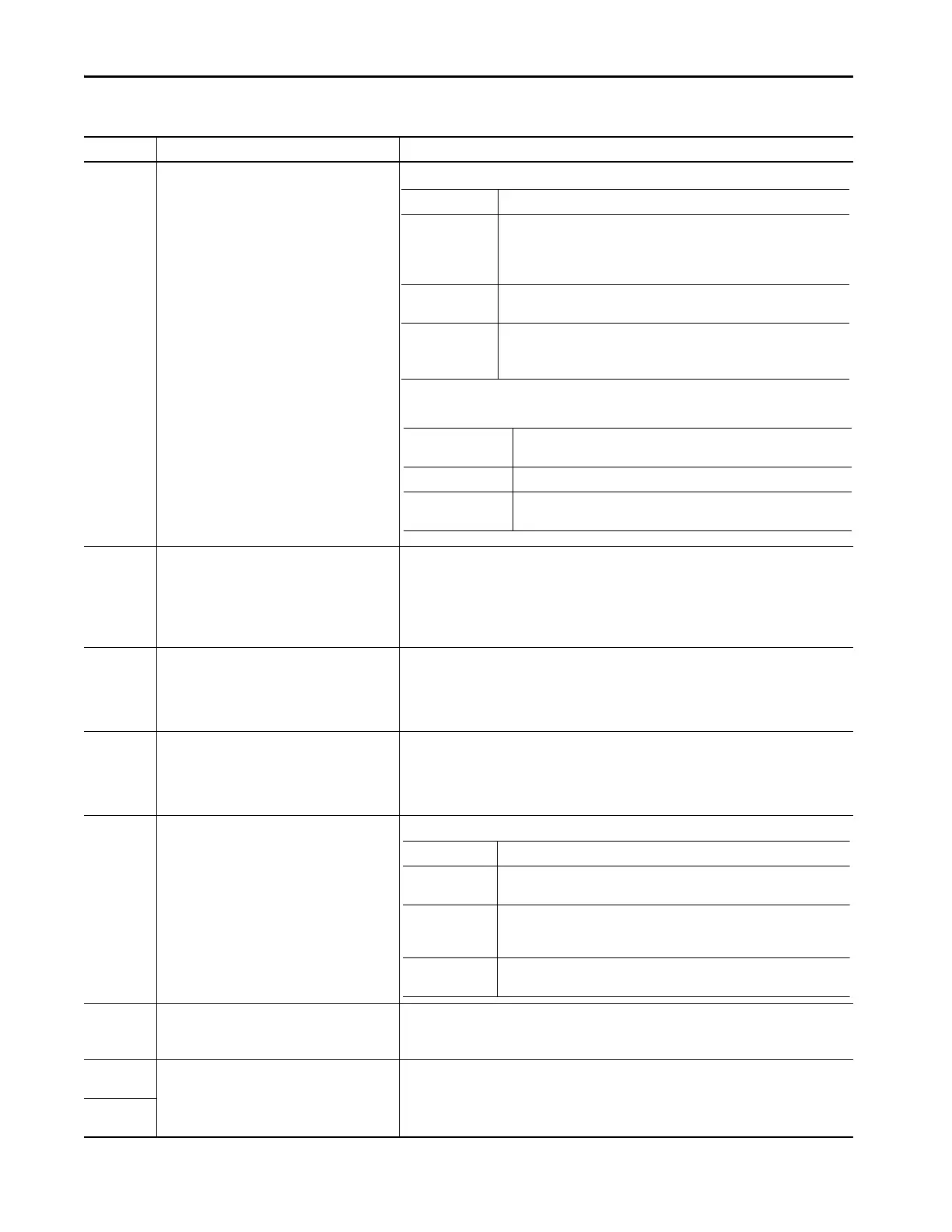

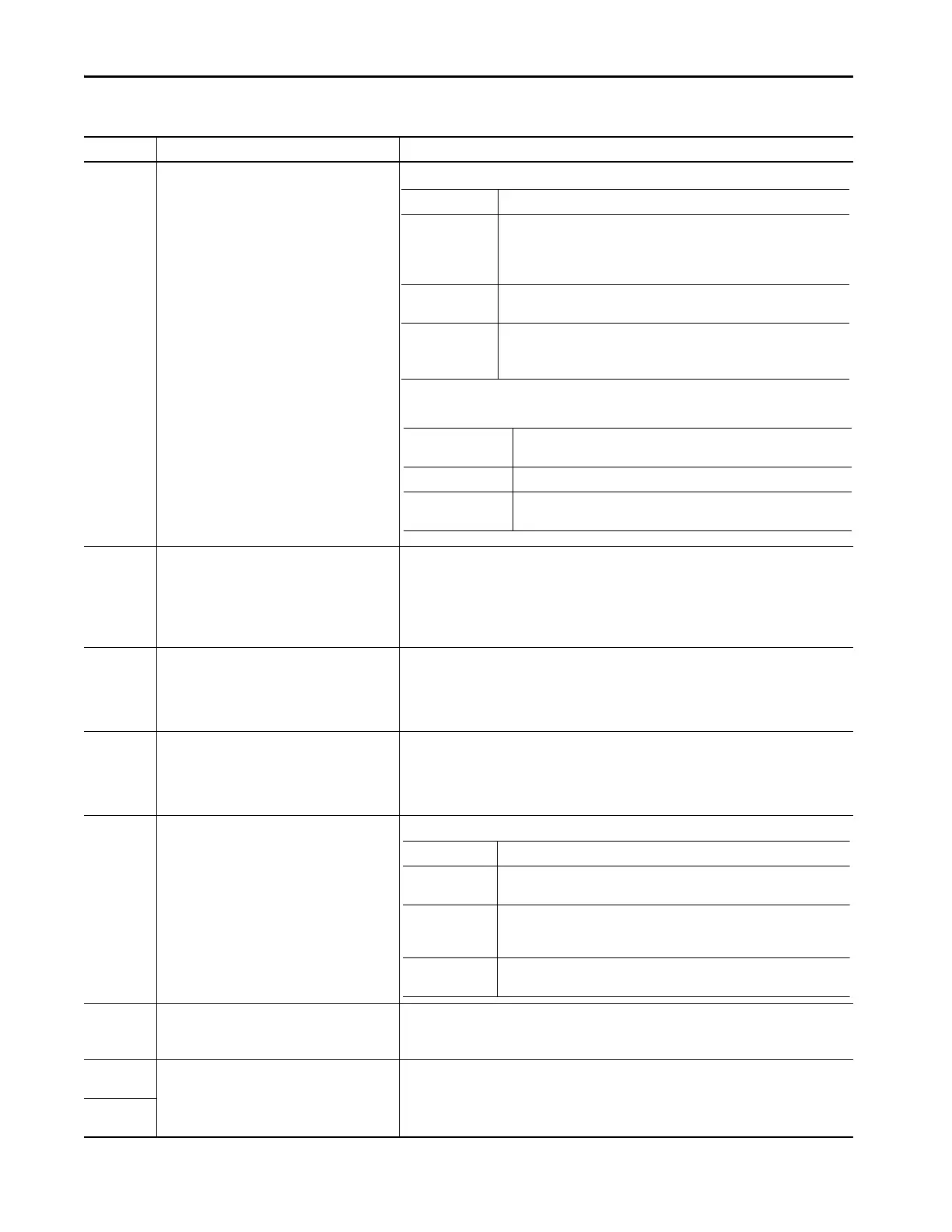

Transducer

State

Behavior

Select from:

•Transducer Fault Considered

•Transducer Fault Monitored

• Transducer Fault Not Considered

This selection specifies the behavior of the Measurement Alarm if a transducer fault occurs.

Also consider:

Deadband 0…20 Enter a deadband (hysteresis) as a percentage of the alarm limit or alarm window range. This value is

the amount that the measured value must increase above or fall below (the non-alarm state direction)

the limit after exceeding it before the alarm condition clears.

The intent of the deadband is to minimize “chatter”, where a measurement oscillates around the alarm

limit and causes the alarm condition to set and unset repeatedly.

For window alarms, the deadband is the stated percentage of the range of the window (high - low).

Alert Alarm

Delay Time

0.000…65.500 seconds Enter the time that the measured value must persist at an Alert level before an Alert Alarm condition is

set.

The intent of an alarm delay is to help prevent random electronic or mechanically generated noise. This

noise can create rapid, short-lived signal spikes, from being interpreted, and acted on, as if an actual

alarm condition.

Danger Alarm

Delay Time

0.000…65.500 seconds Enter the time that the measured value must persist at a Danger level before a Danger Alarm condition

is set.

The intent of an alarm delay is to help prevent random electronic or mechanically generated noise. This

noise can create rapid, short-lived signal spikes, from being interpreted, and acted on, as if an actual

alarm condition.

Apply Limits

From

Select from:

• Static Limits

• Static Limits with Adaptive Multipliers

• Output Tag Limits

Select the source for the alarm limits and any applicable multipliers.

Adaptive

Limits

— When the Limit Source is “Static Limits w/ Adaptive Multipliers”, click this option to access the Adaptive

Multipliers editor.

Adaptive Multipliers are uniquely defined for each Measurement Alarm.

Danger High

Limit

Any Enter a value to specify the limit that when the measurement is above/below (unsafe direction) defines

a Danger Alarm condition.

Danger low

Limit

Table 45 - Alarms (continued)

Parameter Values Help

Option Behavior

Transducer Fault

Considered

The Alarm is not evaluated (so never TRUE) if the transducer is in a Fault

condition.

Any alarm that was TRUE (actuated) clears if the associated transducer goes into

fault.

Transducer Fault

Monitored

The Alarm is forced to TRUE (actuated) when the transducer is in a Fault

condition, regardless of the value of the measured parameter.

Transducer Fault

Not Considered

The behavior of the alarm remains strictly defined by the measurement.

Depending on the nature of a transducer fault and the specifics of the

measurement, a fault can force the measurement high, or low.

Dual Channel

Measurements

The preceding table information applies if either sensor faults.

Speed Measurements The preceding table information applies if the speed transducer faults.

Speed Dependent

Measurements

The preceding table information applies if the associated transducer faults

OR if the speed transducer faults.

Option Description

Static Limits The normal mode. The limits are entered directly (so are static), along with one

(static) multiplier that the Setpoint Multiplier function manages.

Static Limits with

Adaptive

Multipliers

The limits are entered directly (so are static), but uses up to five multipliers that

are applied depending on a control parameter.

Output Tag Limits The limits are passed to the module in the Controller Output assembly. No

multiplication is provided.

Loading...

Loading...