Rockwell Automation Publication MOTION-UM002E-EN-P - June 2016 69

Configure an Articulated Independent Robot Chapter 4

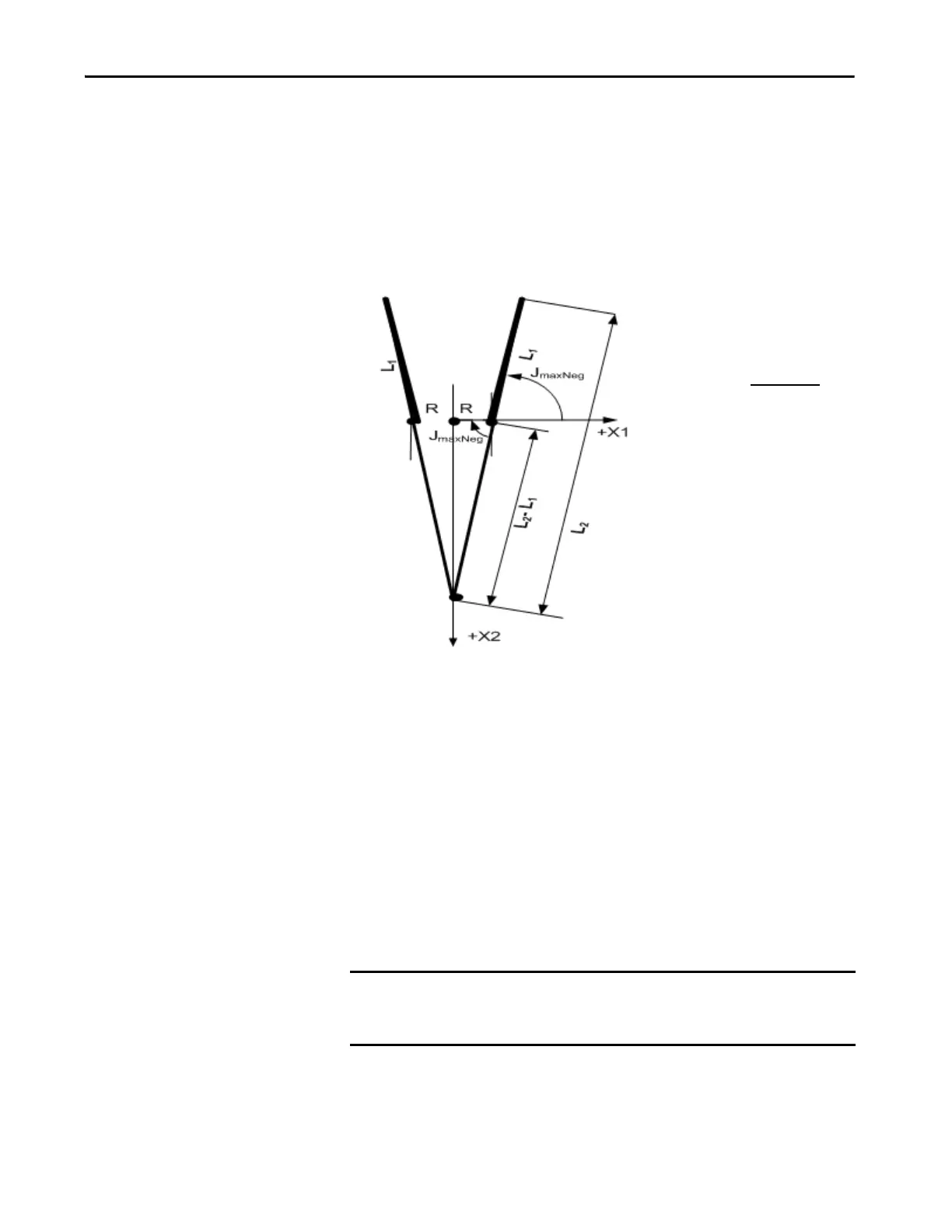

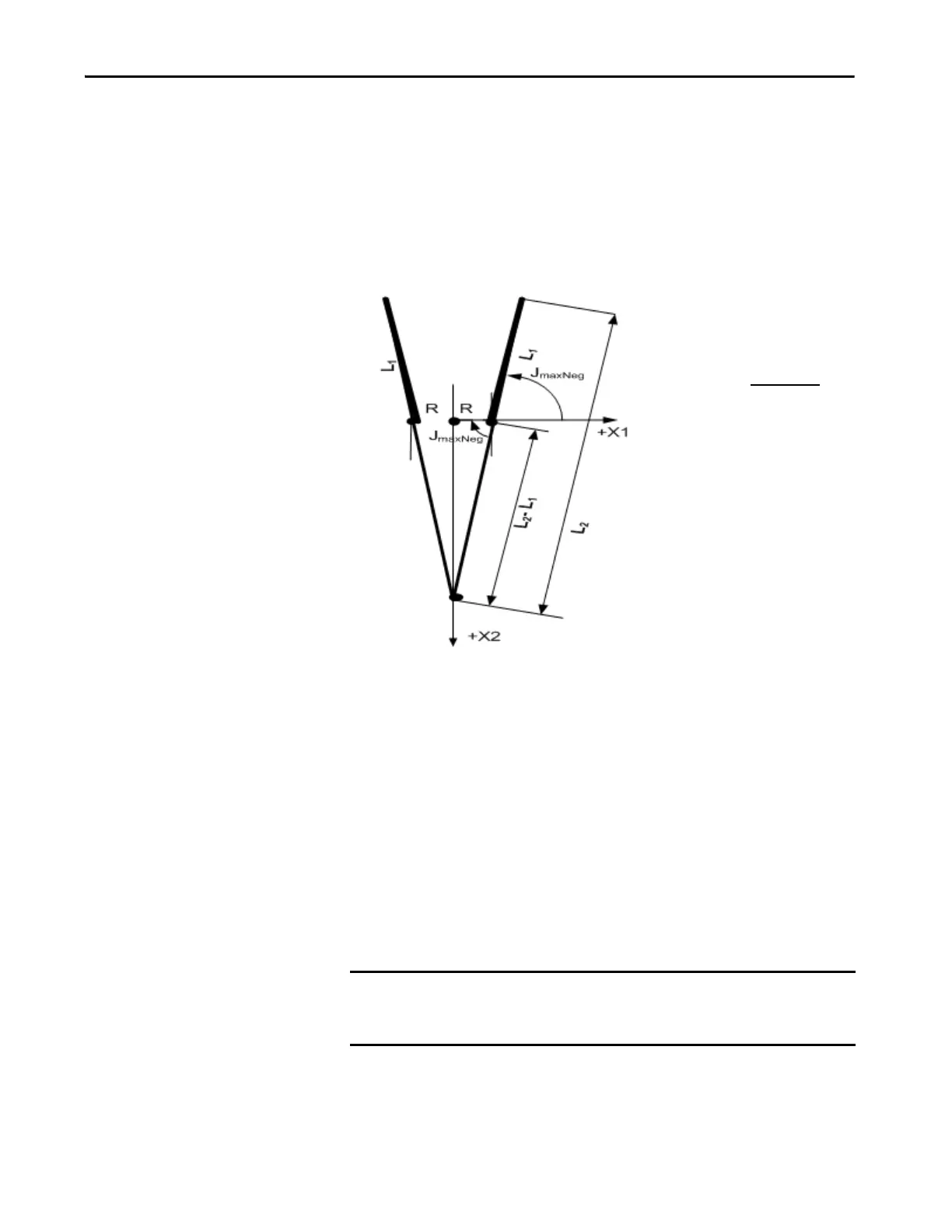

Maximum Negative Joint Limit Condition

The derivations for the maximum negative joint limit applies to the condition

when L1 and L2 are folded back on top of each other.

R is computed by using the base and end-effector offsets values (X1b and X1e).

Figure 22 - Maximum Negative Joint Limit Condition - L1 and L2 are Folded Back on Top of Each

Other

Define Configuration Parameters for a Delta Three-dimensional

Robot

Logix Designer application can be configured for control of robots with

varying reach and payload capacities. As a result, it is very important to know

the configuration parameter values for your robot including:

•Link lengths.

• Base offsets.

• End-effector offsets.

The configuration information is available from the robot manufacturer.

IMPORTANT Verify that the values for the link lengths, base offsets, and end-effector

offsets are entered into the Configuration Parameters dialog by using the

same measurement units.

Maximum Negative Joint Limit Condition

R = absolute value of (X1b - X1e)

JMaxNeg = -cos

-1

Loading...

Loading...