152 Rockwell Automation Publication 825-UM004D-EN-P - November 2012

Chapter 11 Testing & Troubleshooting

2. Using the front panel or MPS Explorer software, record the Phase CT

Ratio and Phase Rotation setting values.

3. Set the phase current angles to apply balanced three-phase currents in

ac

cordance with the Phase Rotation setting. Refer to Figure48 on

page149.

4. S

et each phase current magnitude equal to the values listed in Column 1

of Ta

ble 85. Use the front panel to view the phase current values. The relay

displays the applied current magnitude times the CT Ratio setting.

For the minimum, mid-range, and maximum values, refer to the

I

e

setting range

for a given MCM converter module. These converter module current ranges are:

• 825-MCM2 (0.5…2.5 A)

• 825-MCM5 (1.0…5.0 A)

• 825-MCM20 (2.5…20 A)

• 825-MCM180 (20…180 A)

• 825-MCM420 (160…420 A)

• 825-MCM630N (160…630 A)

Current Unbalance Element Accuracy

1. Connect the current source to the MCM module as shown in Figure 48.

2. Using the front panel SET/SHOW function or MPS Explorer software,

rec

ord the Phase CT Ratio, Phase Rotation, and Motor FLA (

I

e

) setting

values.

3. Set the phase current angles to apply balanced three-phase currents in

ac

cordance with the Phase Rotation setting. See Figure 48.

4. Apply the appropriate magnitude for each phase current as shown in

colu

mn 1 of Tabl e 86

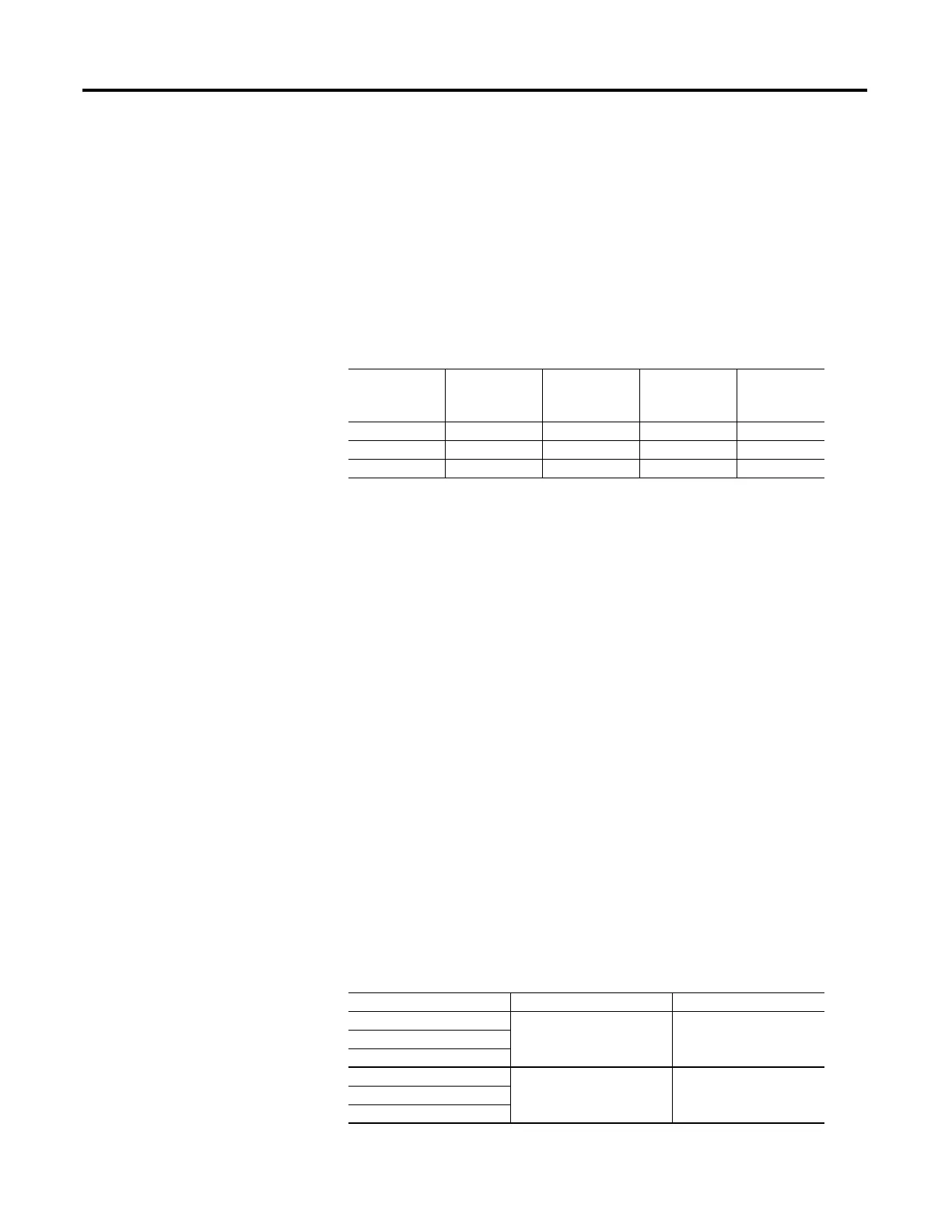

Table 85 - Phase Current Measuring Accuracy

|I|

Applied

(A secondary)

Expected

Reading

CTR1 x |I|

A–Phase

Reading

(A primary)

B–Phase

Reading

(A primary)

C–Phase

Reading

(A primary)

Minimum

Mid-range

Maximum

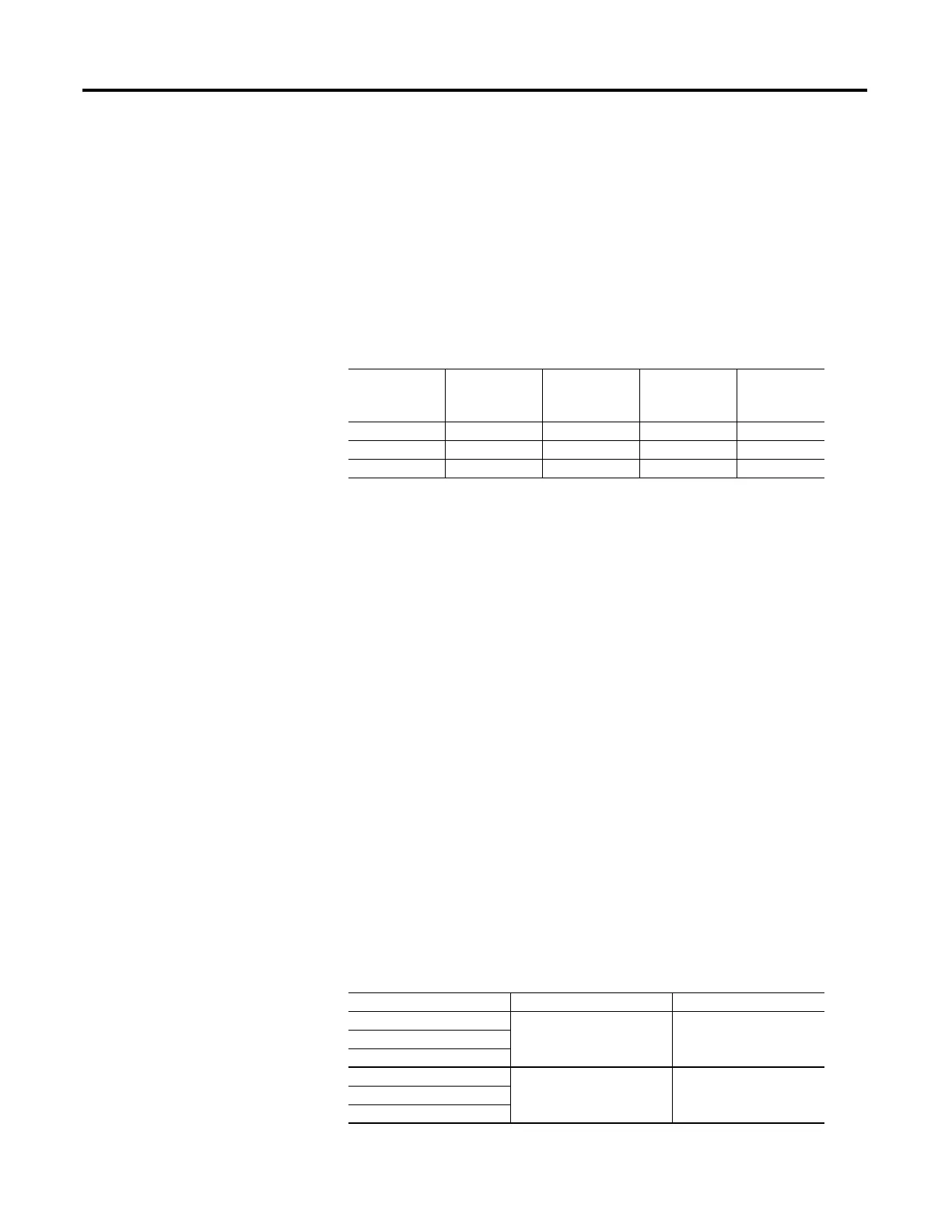

Table 86 - Current Unbalance Measuring Accuracy

|I| Applied (A secondary) Expected Reading (%) Actual Reading (%)

|IA| = 0.9 • FLA 7%

|IB| = FLA

|IC| = FLA

|IA| = 0.75 • FLA 17%

|IB| = FLA

|IC| = FLA

Loading...

Loading...