Rockwell Automation Publication 2198-UM002G-EN-P - February 2019 171

Connect the Kinetix 5700 Drive System Chapter 5

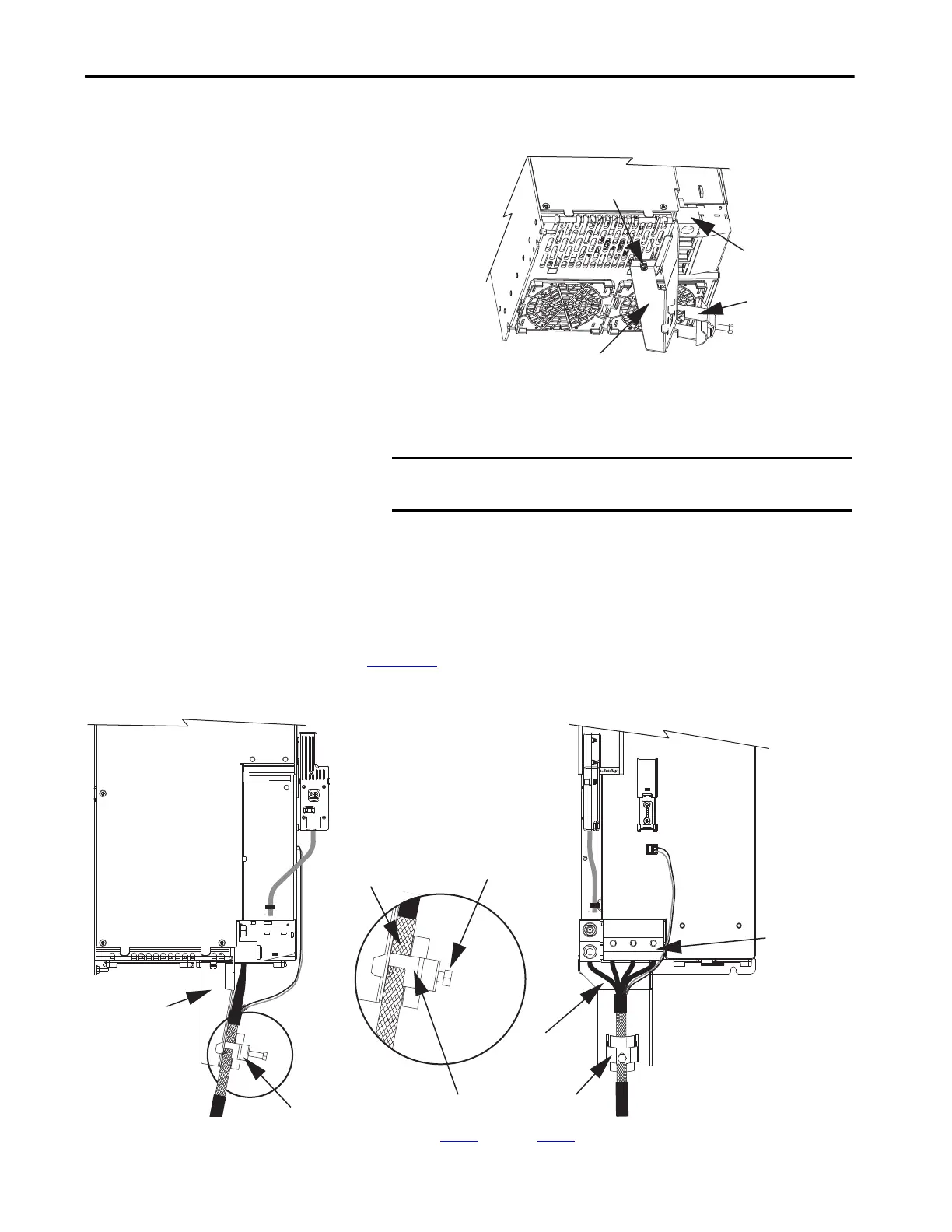

2. Align the clamp-bracket captive screw with hole in chassis and tighten to

1.6 N•m (14 lb•in).

3. Loosen the clamp screw.

4. Position the exposed portion of the cable braid directly in line with the

clamp.

5. Tighten the clamp screw.

Make sure the cable clamp tightens around the overall cable shield and

provides a good bond between the cable shield and the drive chassis.

Torque value 5.6 N•m (50 lb•in), max.

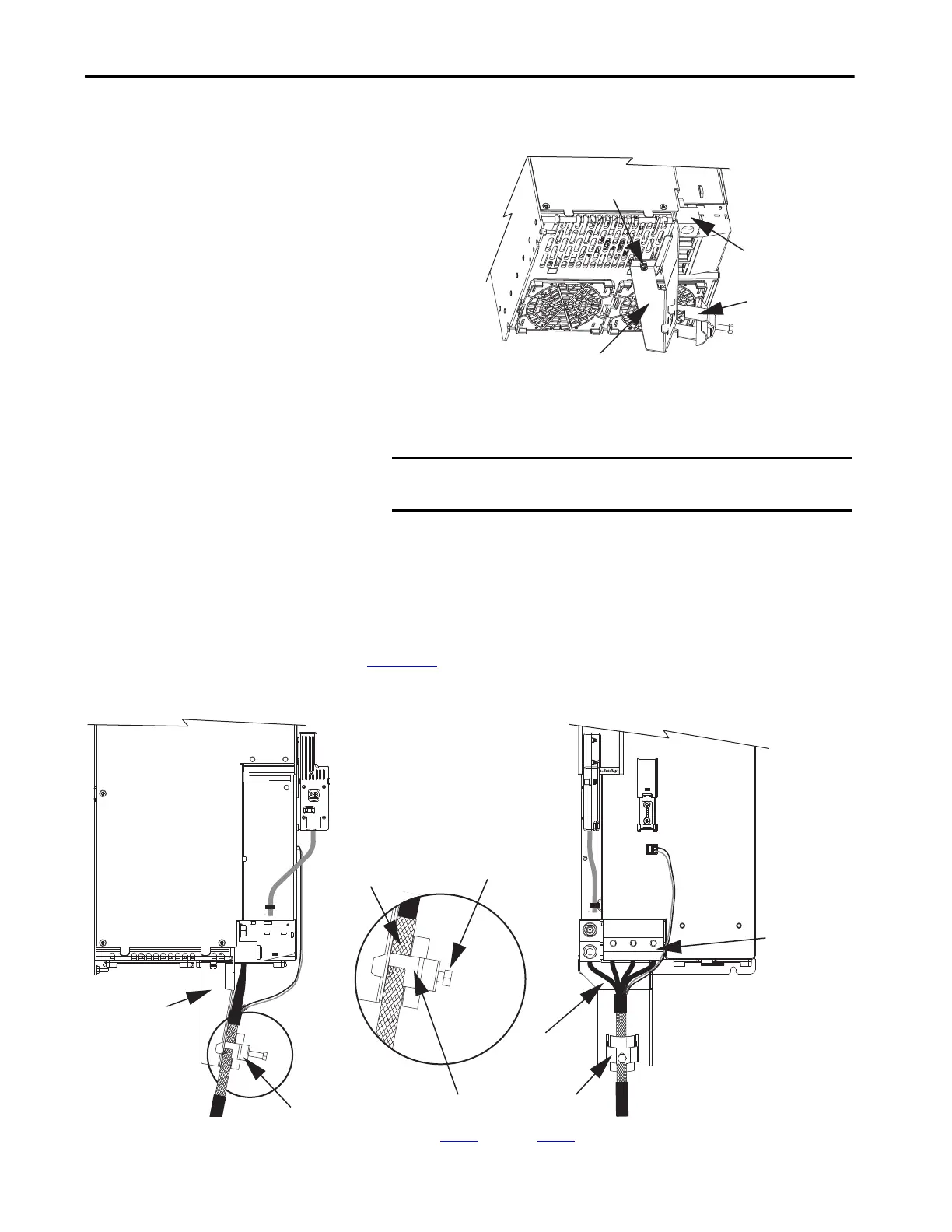

In Figure 113

, the Bulletin 2090 (4 and 2 AWG) cable requires no preparation.

Figure 113 - Single-axis Inverter Cable Installation (4 and 2 AWG cables)

6. Repeat step 1 through step 5 for each drive in multi-axis configurations.

2198-S263-ERSx or

2198-S312-ERSx

Single-axis Inverter

(bottom view)

Cable Clamp

Cable Clamp Bracket

Ground Conductor

Termination Block

Captive Screw

IMPORTANT Make sure the clamp is aligned with the shield braid and not the

heat shrink.

MBRK

+

-

21mm (4 AWG-250 kcmil)

15-20 Nm (132-177 lbin)

2

W V U

Motor Cable Shield Clamp

2198-K57CK-D15M

Motor Feedback

Connector Kit

Motor Power

(MP) Connector

Motor Brake

(BC) Connector

Clamp Screw

(M10)

2198-S263-ERSx or

2198-S312-ERSx

Single-axis Inverter

(front view)

Overall Cable Shield

Under Clamp

Motor Power

Conductors

Bulletin 2090-CPBM7DF

Power/Brake Cable

Cable Clamp

Cable Clamp

Bracket

2198-S263-ERSx or

2198-S312-ERSx

Single-axis Inverter

(side view)

Loading...

Loading...