Rockwell Automation Publication 2198-UM002G-EN-P - February 2019 341

Appendix A

Interconnect Diagrams

This appendix provides wiring examples and system block diagrams for your

Kinetix® 5700 system components.

Interconnect Diagram Notes

This appendix provides wiring examples to assist you in wiring the

Kinetix 5700 drive system. These notes apply to the wiring examples on the

following pages.

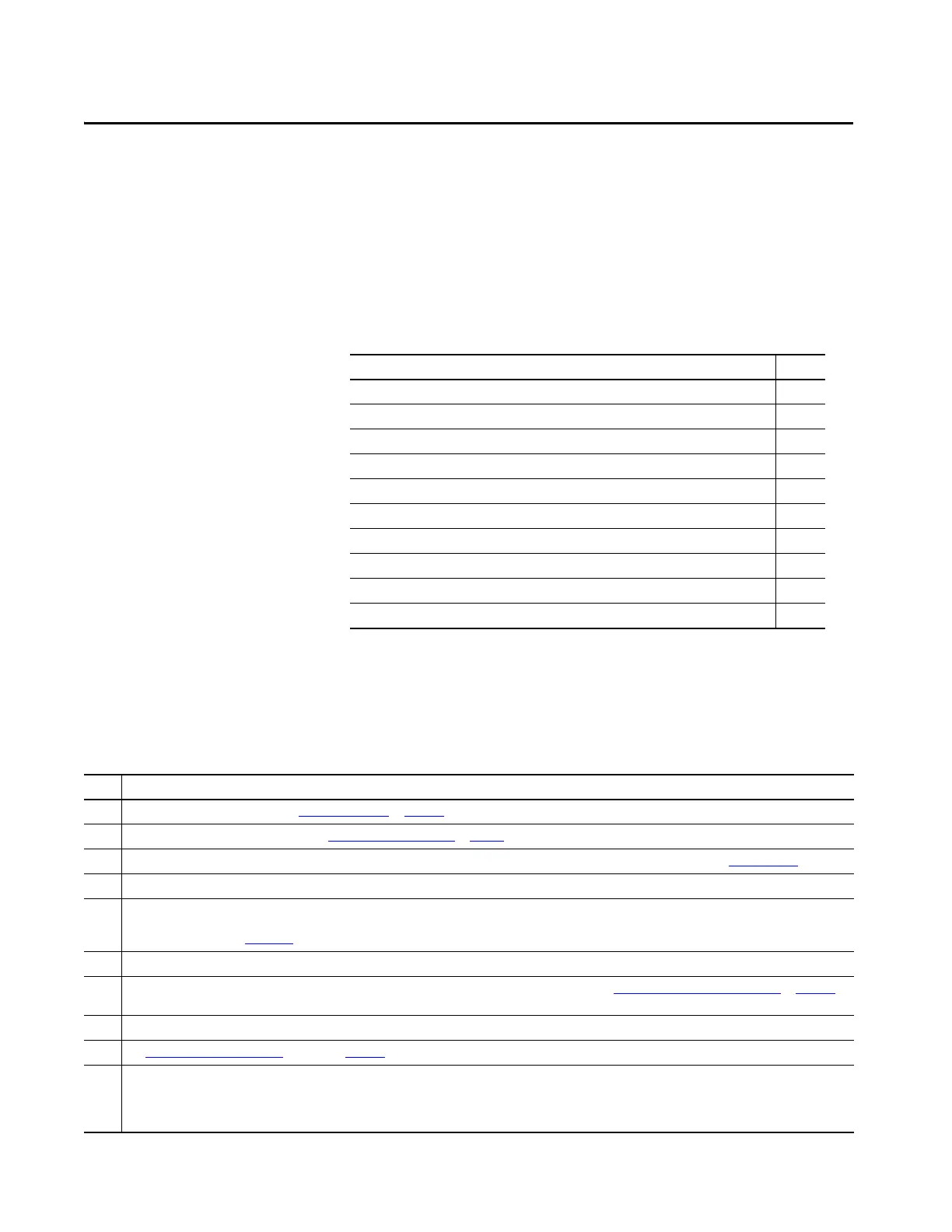

Topic Page

Interconnect Diagram Notes 341

Power Wiring Examples 343

Capacitor Module Status Wiring Example 357

DC-bus Conditioner Module Status Wiring Example 357

Contactor Wiring Examples 358

Passive Shunt Wiring Examples 359

Active Shunt Wiring Examples 360

Kinetix 5700 Servo Drive and Rotary Motor Wiring Examples 362

Kinetix 5700 Servo Drive and Linear Actuator Wiring Examples 367

System Block Diagrams 373

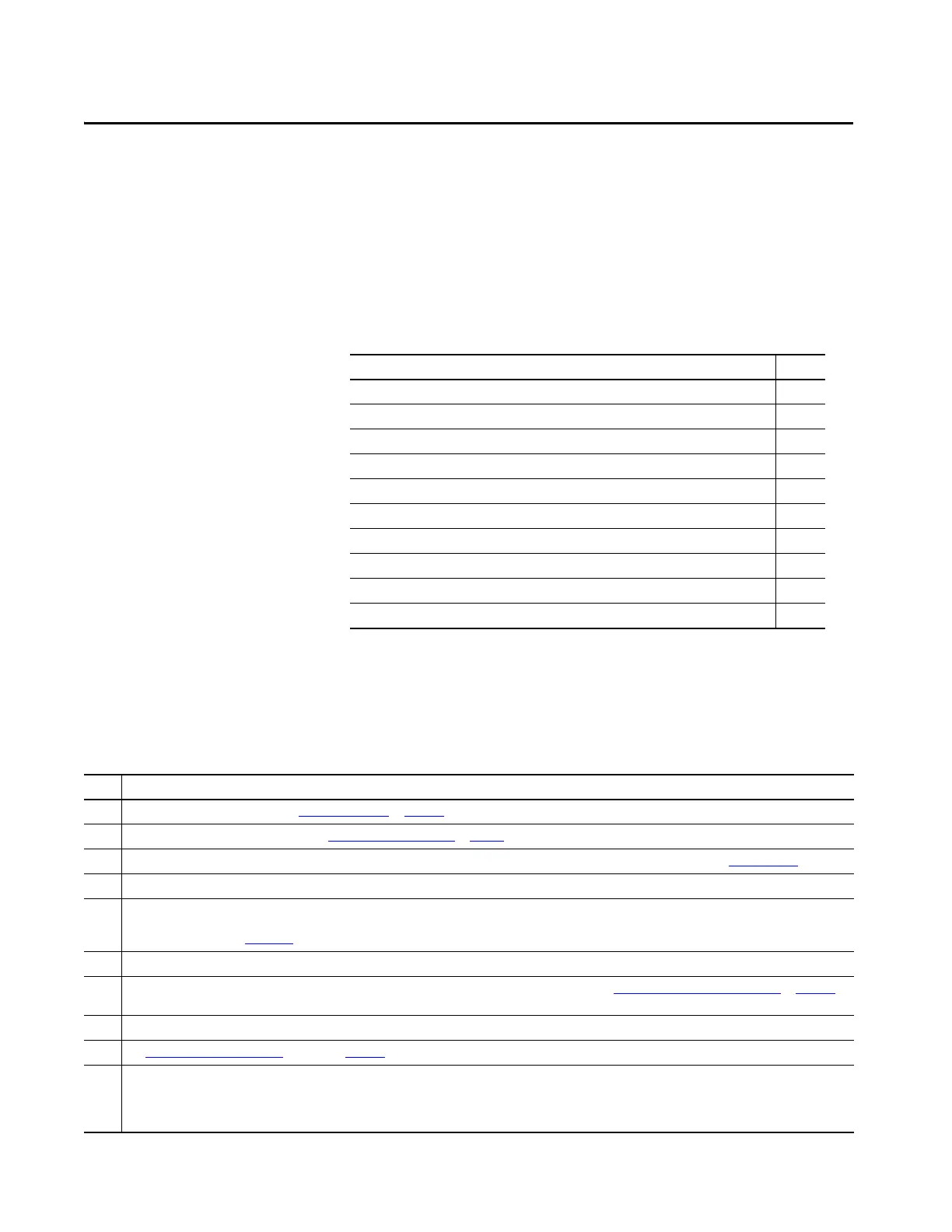

Table 170 - Interconnect Diagram Notes

Note Information

1 For power wiring specifications, refer to Wiring Requirements

on page 141.

2 For input fuse and circuit breaker sizes, refer to Circuit Breaker/Fuse Selection

on page 48.

3 For fuse and circuit breaker sizes and other 8720MC-RPS specifications, see the 8720MC Regenerative Power Supply User Manual, publication 8720MC-RM001.

4 The iTRAK® power supply must have three-phase power sourced from grounded-wye power distribution.

5 AC (EMC) line filter is required for CE compliance. Place line filter as close to the drive as possible and do not route very dirty wires in wireway. If routing in wireway is

unavoidable, use shielded cable with shields grounded to the drive chassis and filter case. For AC line filter specifications, refer to Kinetix Servo Drives Specifications

Technical Data, publication KNX-TD003

. 2198-DBRxx-F line filters are preferred.

6 Terminal block is required to make connections.

7 Cable shield clamp must be used to meet CE requirements with Bulletin 2090 power cables 2 AWG and smaller. See Customer-supplied Motor Power Cables

on page 178 to

meet CE when wiring 2198-S263-ERSx and 2198-S312-ERSx drives with power cables larger than 2 AWG.

8 2198-Dxxx -ERSx dual-axis inverters include separate digital inputs, DSL feedback, universal feedback, motor power, and motor brake wiring plugs for each axis.

9See Digital Inputs Connector Pinouts

beginning on page 103 for digital input configurable functions and default settings.

10 • When a 2198-Sxxx-ERSx single-axis inverter is the first drive module (adjacent to the 2198-CAPMOD-2240 capacitor module) you must configure the Digital Input

category in the Logix Designer application as Regeneration OK and wire the IOD connector.

• When a 2198-Dxxx-ERSx dual-axis inverter is the first drive module (adjacent to the 2198-CAPMOD-2240 capacitor module) and Axis 1 and 3 are used, you must

configure the Digital Input category in the Logix Designer application as Regeneration OK and wire the IOD connector for each axis.

Loading...

Loading...