16 Rockwell Automation Publication 6000-TG100A-EN-P - September 2020

Chapter 1 Before You Begin Tests, Maintenance, or Repairs

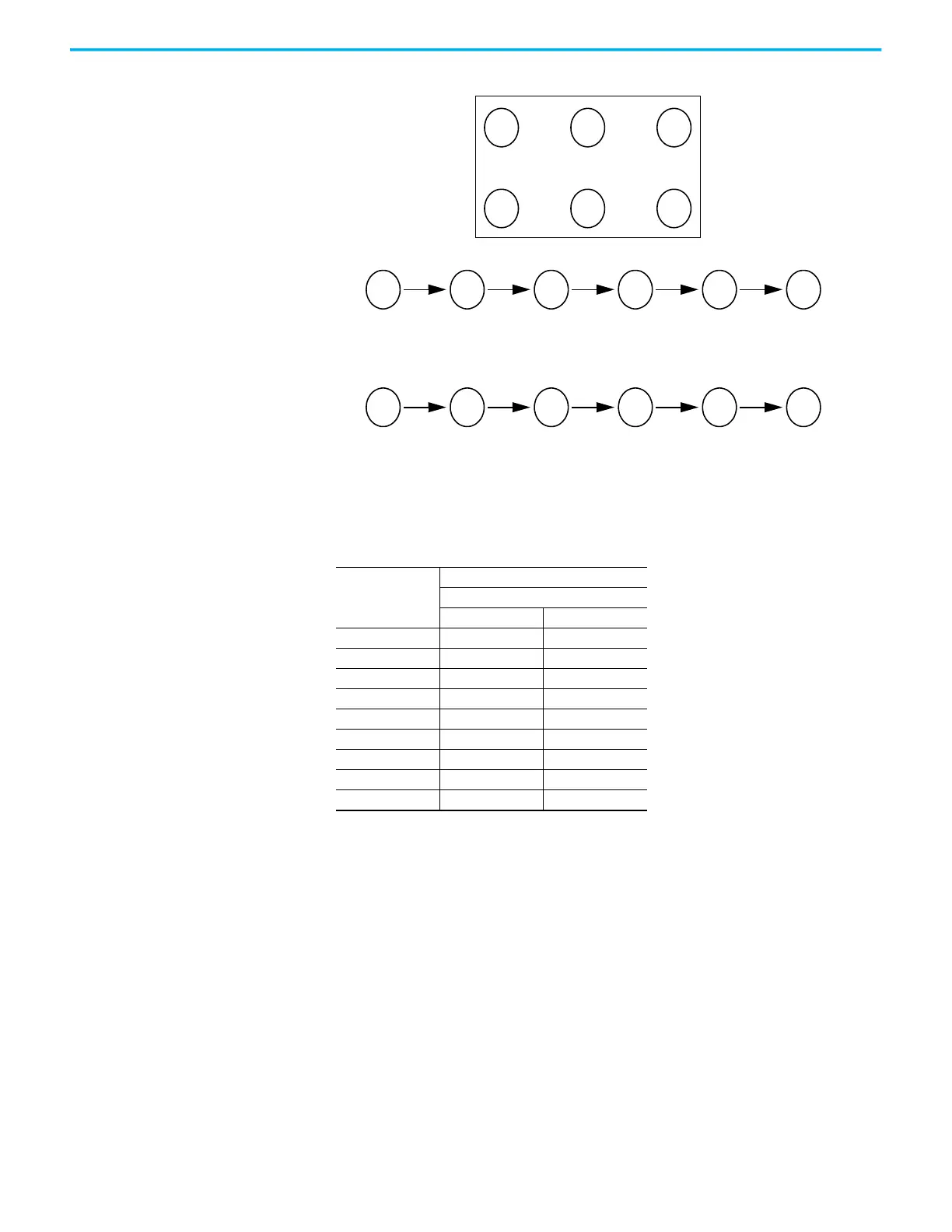

Figure 3 - Six-point Mounting

Torque Requirements Proper tightening torque must be used for installation and wiring.

6 42

3 51

3 4

Initial Sequence

1 2 65

Final Sequence

3 41 2 65

Do not exceed 0.7 N•m (6 lb•in) on initial torque of all six screws.

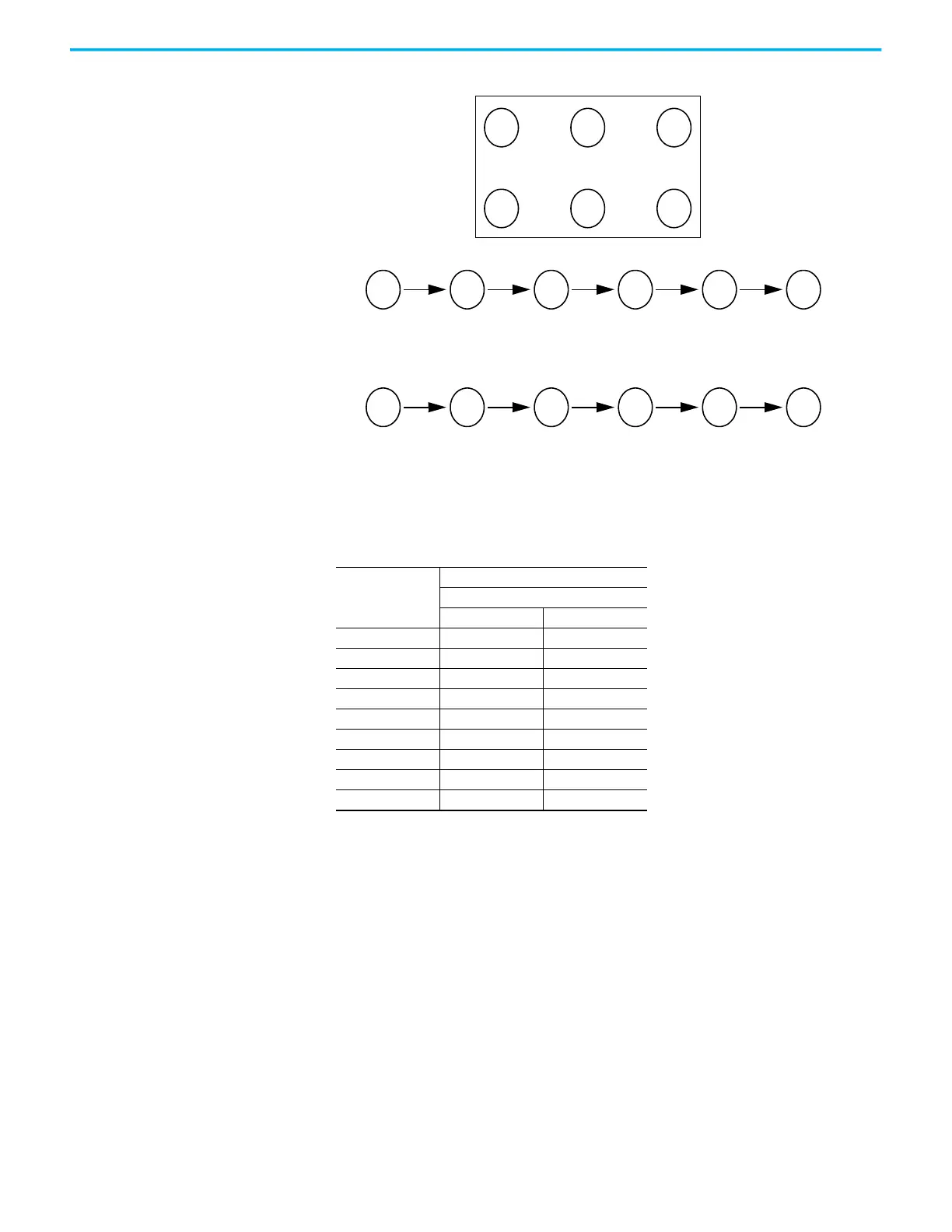

Table 2 - Torque Requirements

Thread Size

Torque

Class 8.8

N•m lb•ft

M4 3.0 2.2

M5 5.9 4.4

M6 10.5 7.7

M8 26.0 19.2

M10 51.0 37.6

M12 89.0 65.7

M14 141.0 104.1

M16 215.0 158.7

M20 420.0 310.0

Loading...

Loading...