18 Rockwell Automation Publication 6000-TG100A-EN-P - September 2020

Chapter 2 Preventative Maintenance and Component Replacement

Maintenance Schedule The codes that are listed in Table 3 are used to identify the task that is

associated with the components that are identified in the preventive

maintenance schedule in Table 4

.

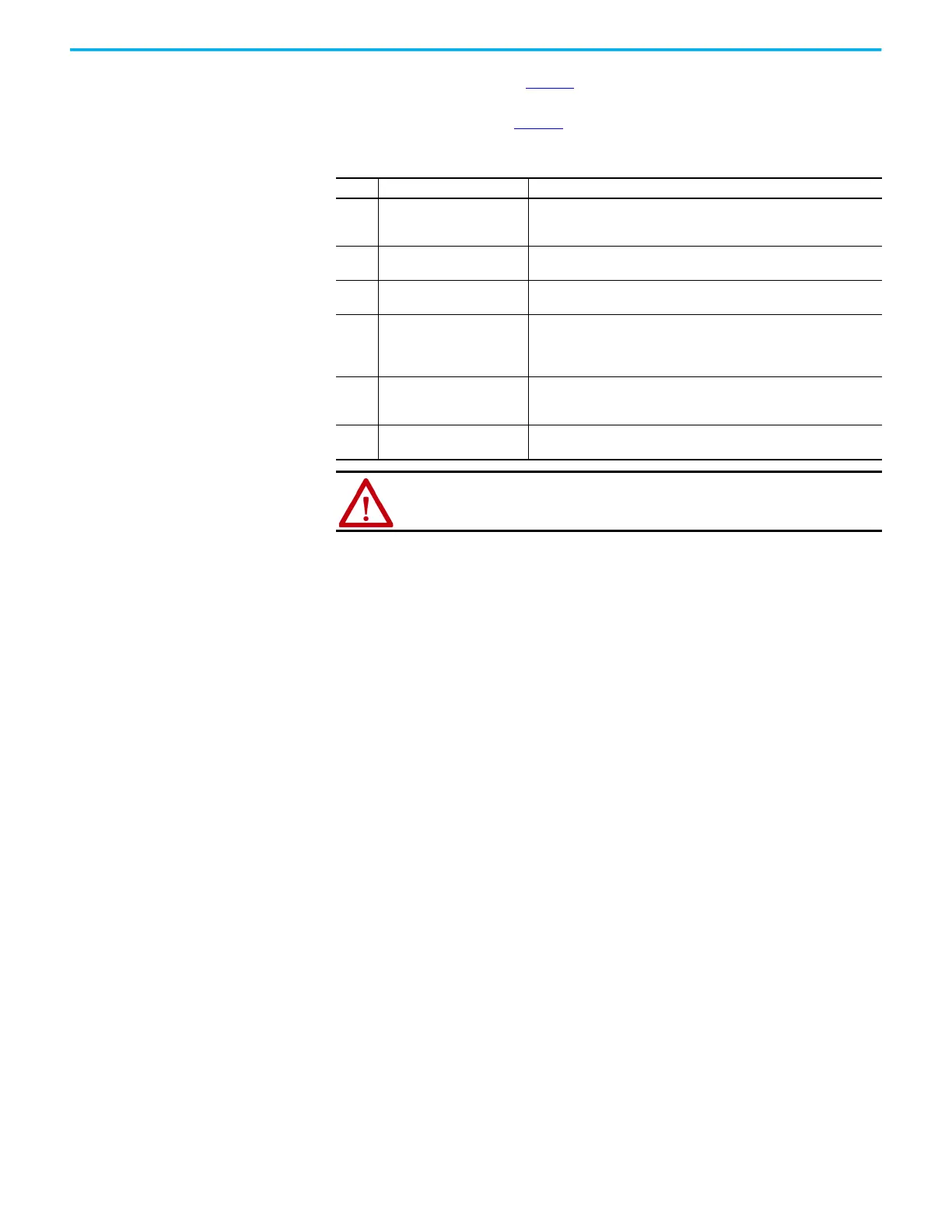

Table 3 - Schedule Codes Explanation

Code Task Description

IInspect

Inspect the component for signs of excessive accumulation of dust, dirt,

or external damage. For example, inspect the filters/fan inlet screens for

debris that can block the airflow path.

CClean

Clean the components that can be reused, specifically the door-mounted

air filters and fan inlet screens.

M Maintain

This type of maintenance task can include an inductance test of line

reactors/DC links, or a full test of an isolation transformer, and so on.

RReplace

This component has reached its mean operational life. Replace the

component to decrease the chance of failure. It is likely that components

can exceed the designed life in the drive, but component life is

dependent on many factors such as usage and heat.

Rv Review

A discussion with Rockwell Automation personnel is recommended to

help determine whether any of the enhancements/changes made to the

drive hardware and control could benefit the application.

RFB/R Refurbishment/Replacement

The parts can be refurbished at lower cost OR the parts can be replaced

with new ones.

ATTENTION: Customers can replace components for the PowerFlex 6000T

drives. However repairs must only be performed by qualified Rockwell

Automation personnel.

Loading...

Loading...