Rockwell Automation Publication 6000-TG100A-EN-P - September 2020 17

Chapter 2

Preventative Maintenance and Component

Replacement

This chapter provides information on preventative maintenance for

components that can affect the life and operational characteristics of

PowerFlex 6000T drives.

Recommended

Preventative Maintenance

The drive can experience reduced service life if operated outside of its design

parameters. Verify that the operating environment is within specifications.

Daily inspection and regular maintenance helps maximize the service life of

the equipment.

This annual preventative maintenance program includes the following

primary tasks:

• A visual inspection of all drive components accessible from the front of

the unit.

• Power supply voltage level checks

• General cleaning and maintenance

• Tightness checks on all accessible power connections

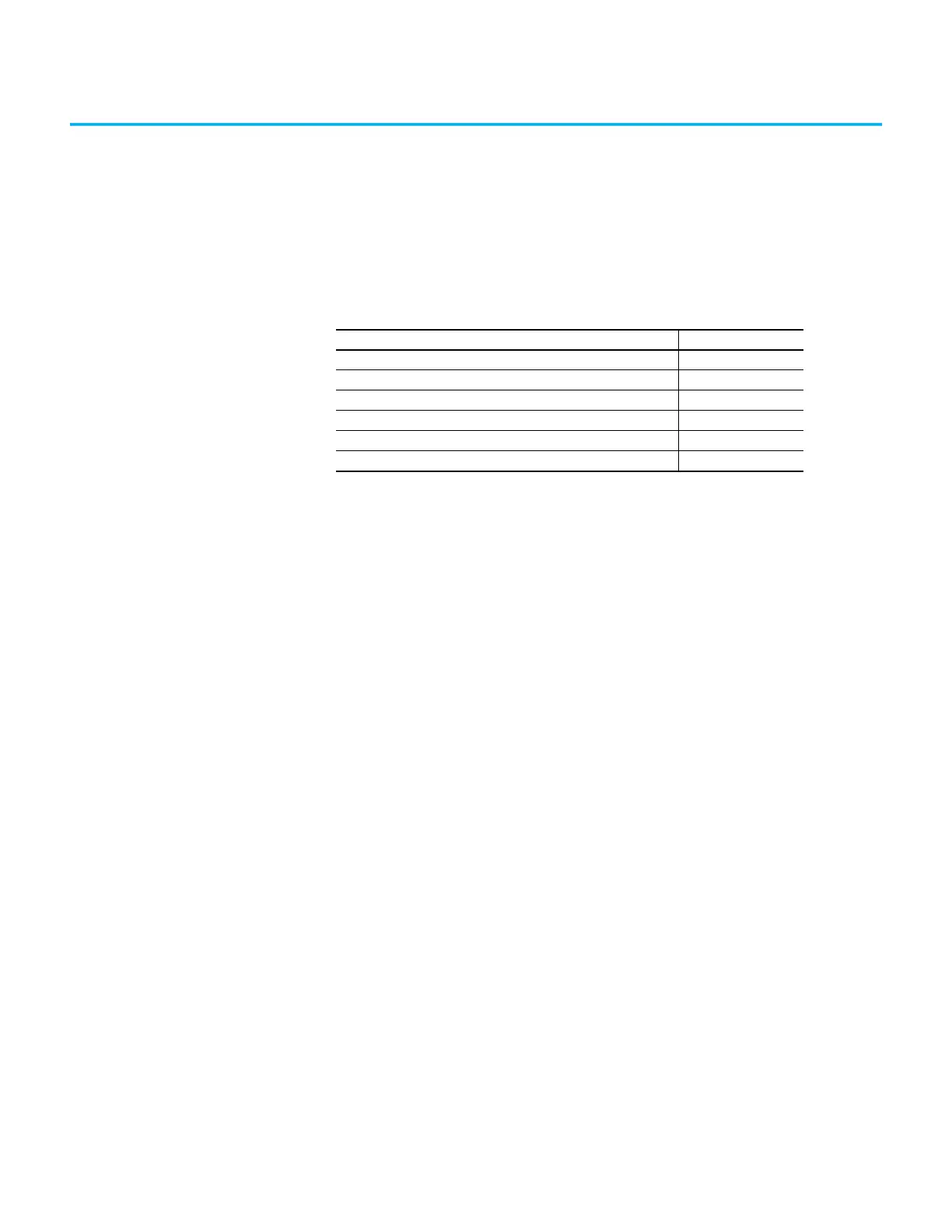

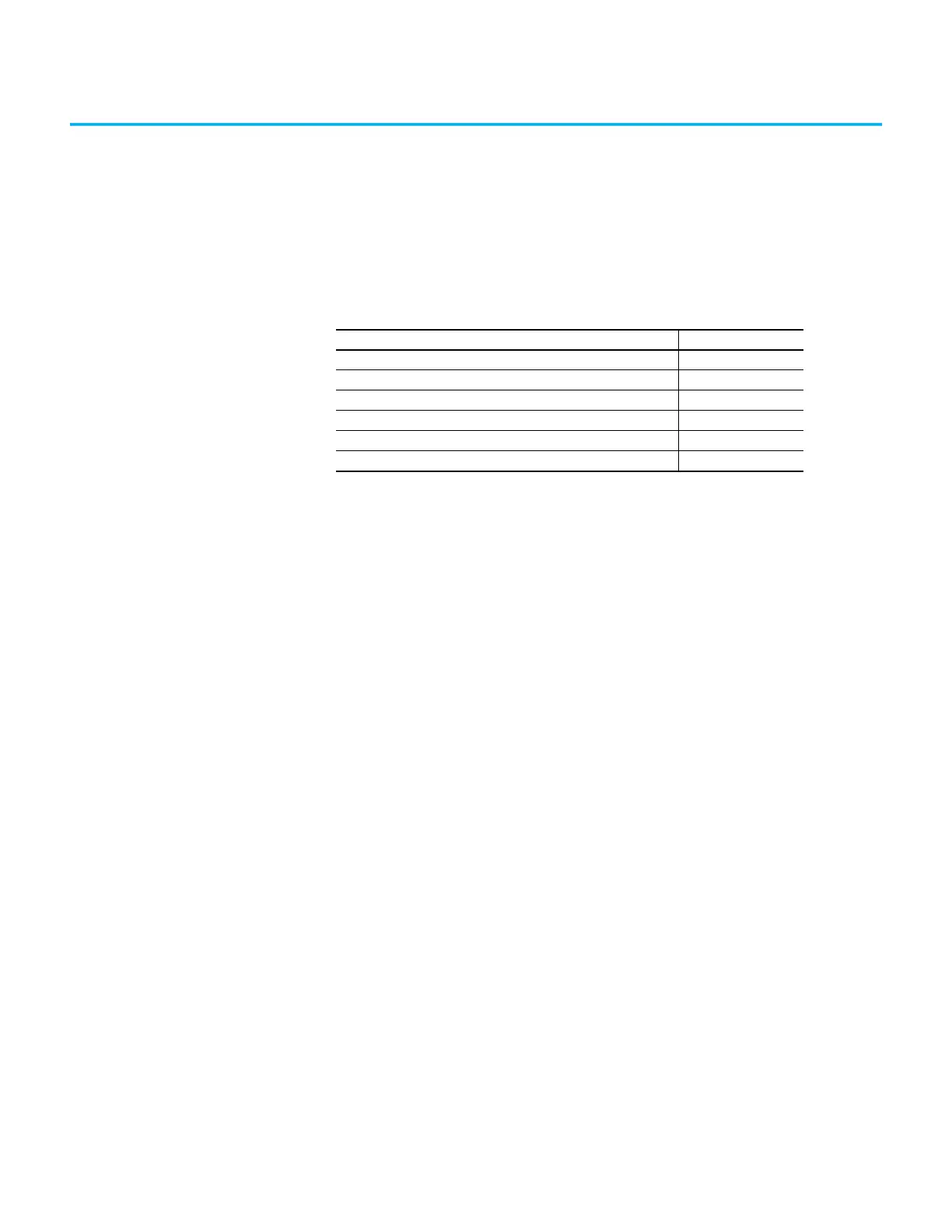

Topic Page

Recommended Preventative Maintenance 17

Maintenance Schedule 18

Maintenance of Industrial Control Equipment 20

Physical Checks 22

General Tasks 24

Final Report 25

Loading...

Loading...