Rockwell Automation Publication 6000-TG100A-EN-P - September 2020 27

Chapter 3

Component Inspection and Test Procedures

This chapter provides details on how to inspect and test the major components

of the drive and includes recommendations for repairs. Review the

Troubleshooting chapter in the PowerFlex 6000T Drives Programming

Manual, publication 6000-PM100

, for information on conditions that can

cause a fault or alarm and how to troubleshoot these conditions.

Component Inspection and

Maintenance

Visually inspect the door filters and major components on the control pod,

power cells, and components for dirt and damage. Dirt build-up on some

components can lead to component damage or failure. Avoid damage to the

product by replacing components and/or circuit boards with burn marks,

breakage, or foil delamination. Follow these inspection and maintenance

instructions along with the Recommended Preventative Maintenance

information on page 17

.

1. Review the Product Advisories on page 11

.

2. Remove power from the system. See Remove Power from the System on

page 13

.

3. Remove the filters from the enclosure doors and inspect for dirt buildup

or blockage. Clean or replace all filters as necessary.

See the procedures on page 28

for removal instructions.

4. Inspect the enclosure fan assemblies for blockage and verify free

rotation. Clean or replace as necessary.

See the procedures on page 30

for removal instructions:

5. Inspect the door position limit switches for obvious signs of damage,

dust, or foreign material. Remove any dirt or foreign material. Wipe

components with an anti-static cloth, where applicable. Check that the

aviation plug has a hand-tight connection.

See the procedures on page 33

for removal instructions:

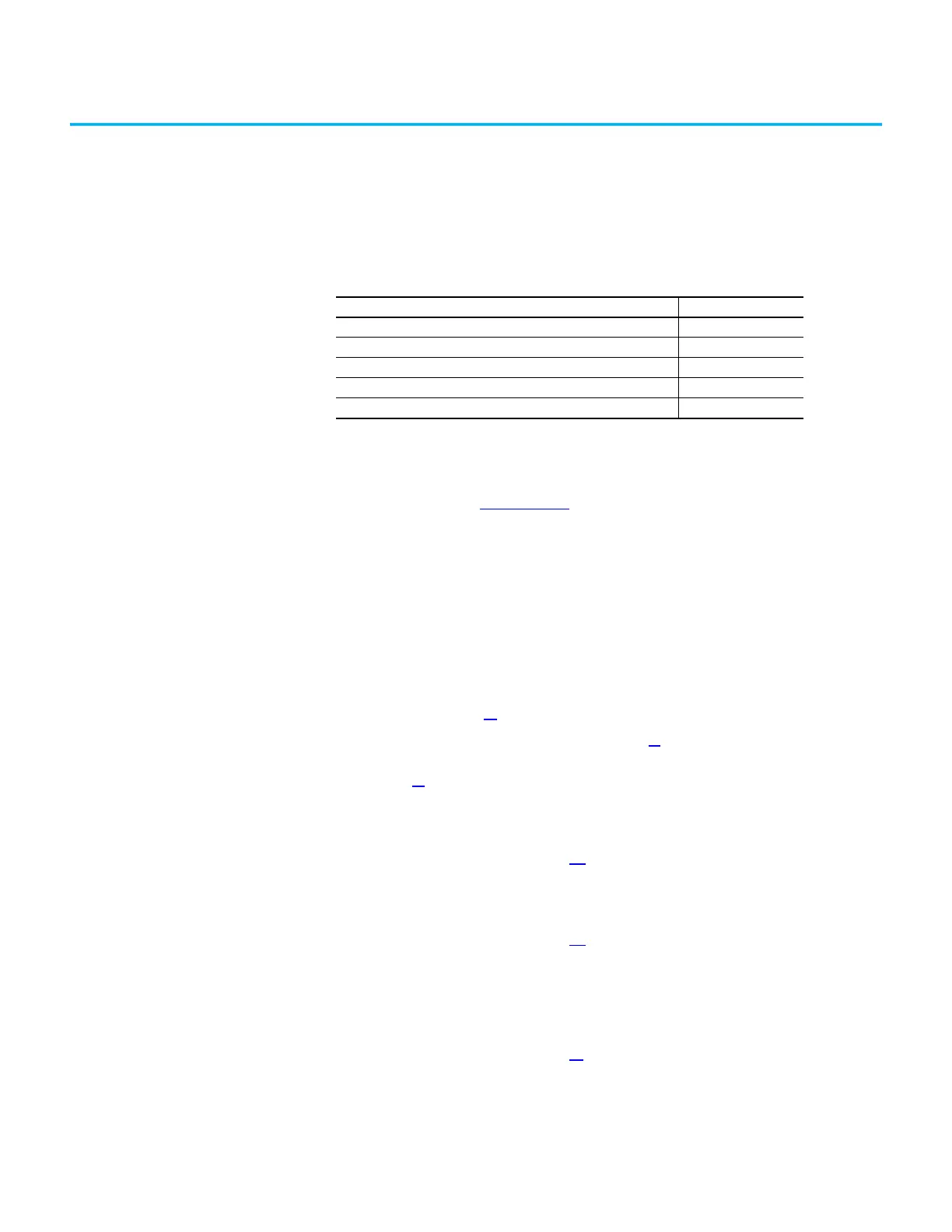

Topic Page

Component Inspection and Maintenance 27

Replace/Clean Door-mounted Air Filters 28

Inspect Top Mounted Cooling Fans 30

Inspect/Replace Door Position Limit Switch 33

Component Fuse Tests 34

Loading...

Loading...