Layout and function

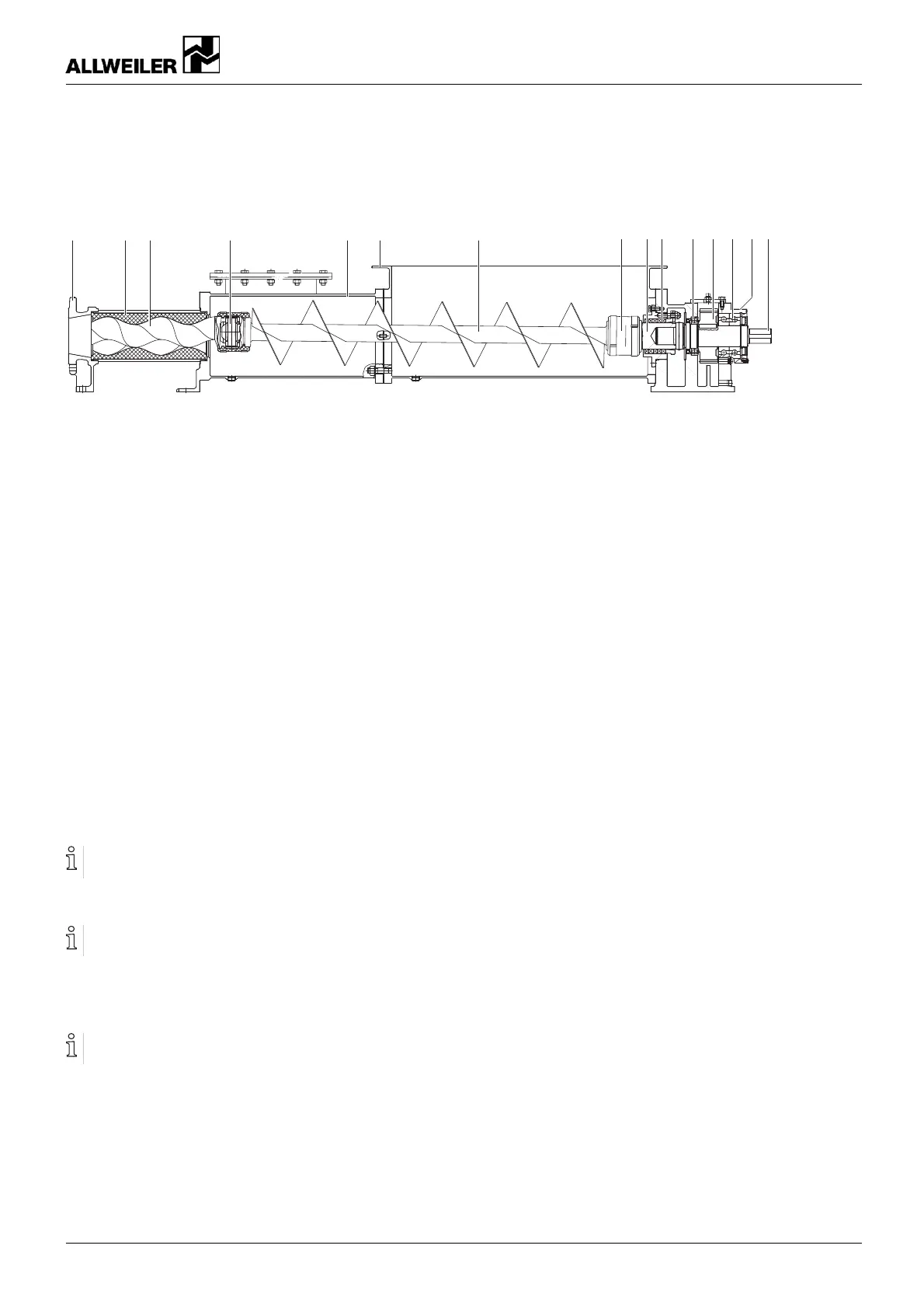

3.2.2 RG version (open-feed version with internal

gearbox mounting)

123 4 56

7489

10

11 10 12 13

Fig. 4 Layout – AE , RG design (ope n-feed version w ith internal gearbox mounting)

1 Pressure side 6

Suction side/suction casing

11

Spur gears

2

Stator

7

Universal joint shaft

12 Bearing pedestal

3 Rotor 8

Stub shaft

13

Top shaft

4 Joint 9

Shaft seal

5

Plug housing 10 Bearing

3.3 Function

• Self-priming, rotating po sitive displacement pump

• One, two, four or eight stages

• The rotor rotates in a station ary stator and displaces the

liquid in the direction of the pump outl et

• Transpo rt and dosage of, for example, highly viscous,

abrasive or solids-containing media

3.4 Shaft seals

Shaft seals used (→ Shaft seals, Page 44).

Only one of the followin g shaft seals can be used.

3.4.1 Packing gland

The packing gland must always leak slightly to carry the

frictional heat aw ay.

Packing gland, housing heated or co oled (optional).

3.4.2 Mechanical seals

Mechanical seals have fu nctional leaks.

• Single-action, unbal anced mechanical seal, optionally with

throttle ring

• Single-action mechanical seal with quenching

• Double-action, balanc ed mechanical seal with external

flushing

3.5 Bearings and lubrication

Close-coupled pump, IE, DE, ZE design:

• Bearing of the stub shaft in the reinforced beari ngs of the

drive motor

Directly mounted pump, ID, ZD, RG design:

• Angular and groove bal l bearings lubricated with grease

and protected from jet water

• Lubrication of the b earings via grease nipples (ID, ZD )

• Oil-lubricated spur gear (RG)

• Special designs possible on request, for example, oil bath

lubrication (ID)

Universal joint shaft:

• Oil-lubricated and liquid-en capsulated pin joints

260371 – 176-982/0 BA-2020.05 en-US AE 11

Loading...

Loading...