Setup and connection

5.7 Aligning the coupling precisely

Applies t o base plate versio n with c oupling

DANGER

Risk of death due to rotating parts!

Isolate the motor from its supply voltage and keep it locked

when carrying out any fitting o r maintenance work.

NOTE

Material damage due to incorrect alignment of the cou-

pling!

Align the motor exactly to the pump if there is any vertical,

lateral or angular misalignment.

For detailed information and spe c ial couplin gs: (→ manu-

facturer ’s specifications).

Checking the alignment of the coupling

Implements, tools and materials:

– Feeler gauge

– Straightedge

– Dial gau ge (for couplings with spacer piece)

– Other suitable tools, e.g. laser alignment instrument

1

2

A

Fig. 1 2 Checking the alignment of the coupling

1. Measure in two planes at an a ngle of 90° on the circumfer-

ence of the coupling.

2. Check the light gap towards the outer diameter with a

straightedge (1):

– Position the straightedge across both halves of the

coupling.

– Align the motor if there is a visible gap on the outer

diameter (→ 5.8 Aligning the motor, Page 21).

3. Measure the gap with a feeler gauge (2):

– Permissible gap (→ setup drawing)

– Use the feeler gauge to m easure the gap (A) between

the coupling halves.

– Align the motor if the gap is too wide (→ 5.8 Aligning

the motor, Page 21).

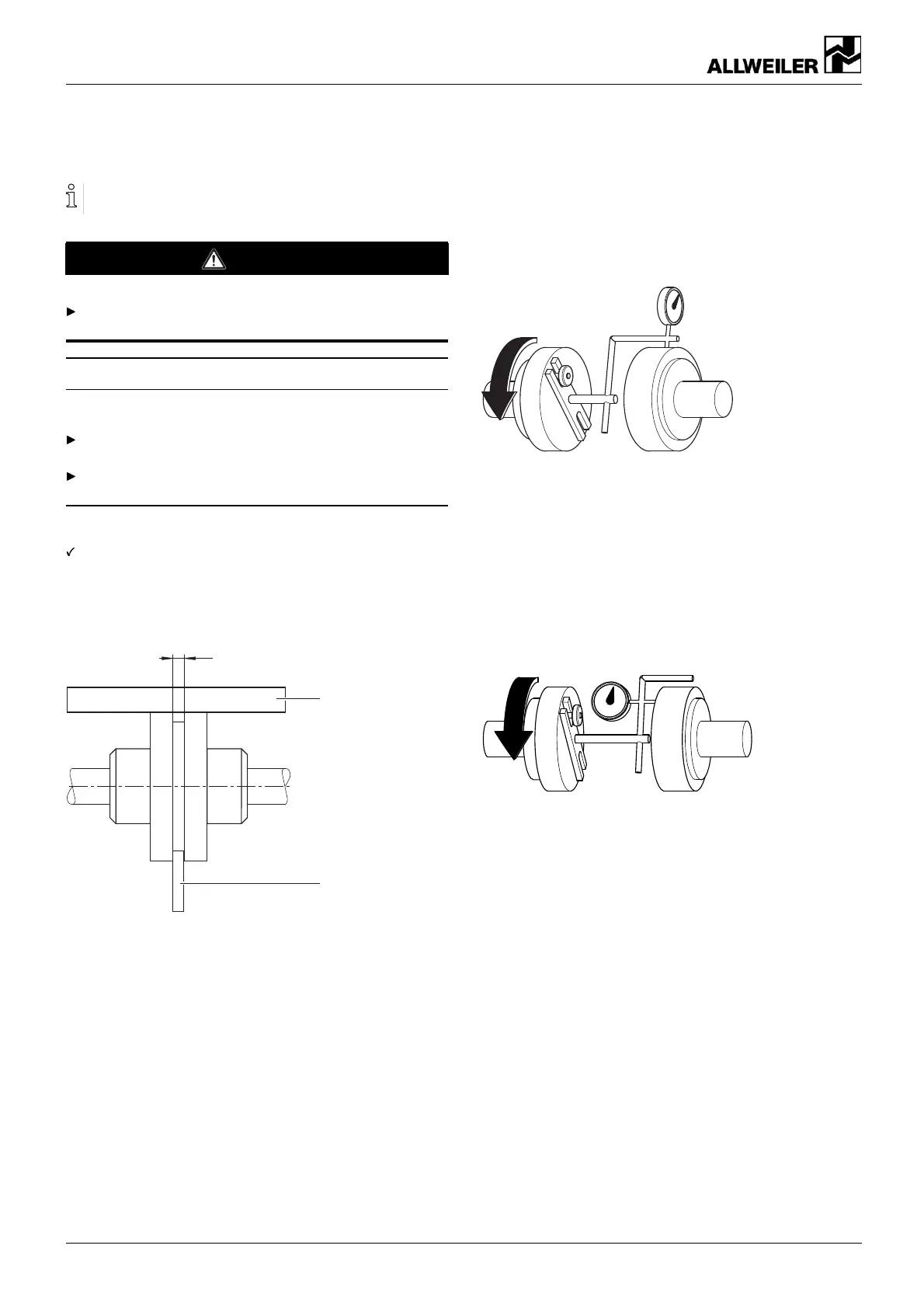

Fig. 13 Checking for lateral and vertical misalignment

4. Check for any lateral or vertical misalignment using the dial

gauge:

– Carry out the measurement as illustrated.

– Align the motor if there is any l ateral or vertical mis-

alignment (→ 5.8 Al igning the mo tor, Page 21).

Permissible axial or radial deviation, measured on the

coupling front or circumference, respectively: ±0.3 mm

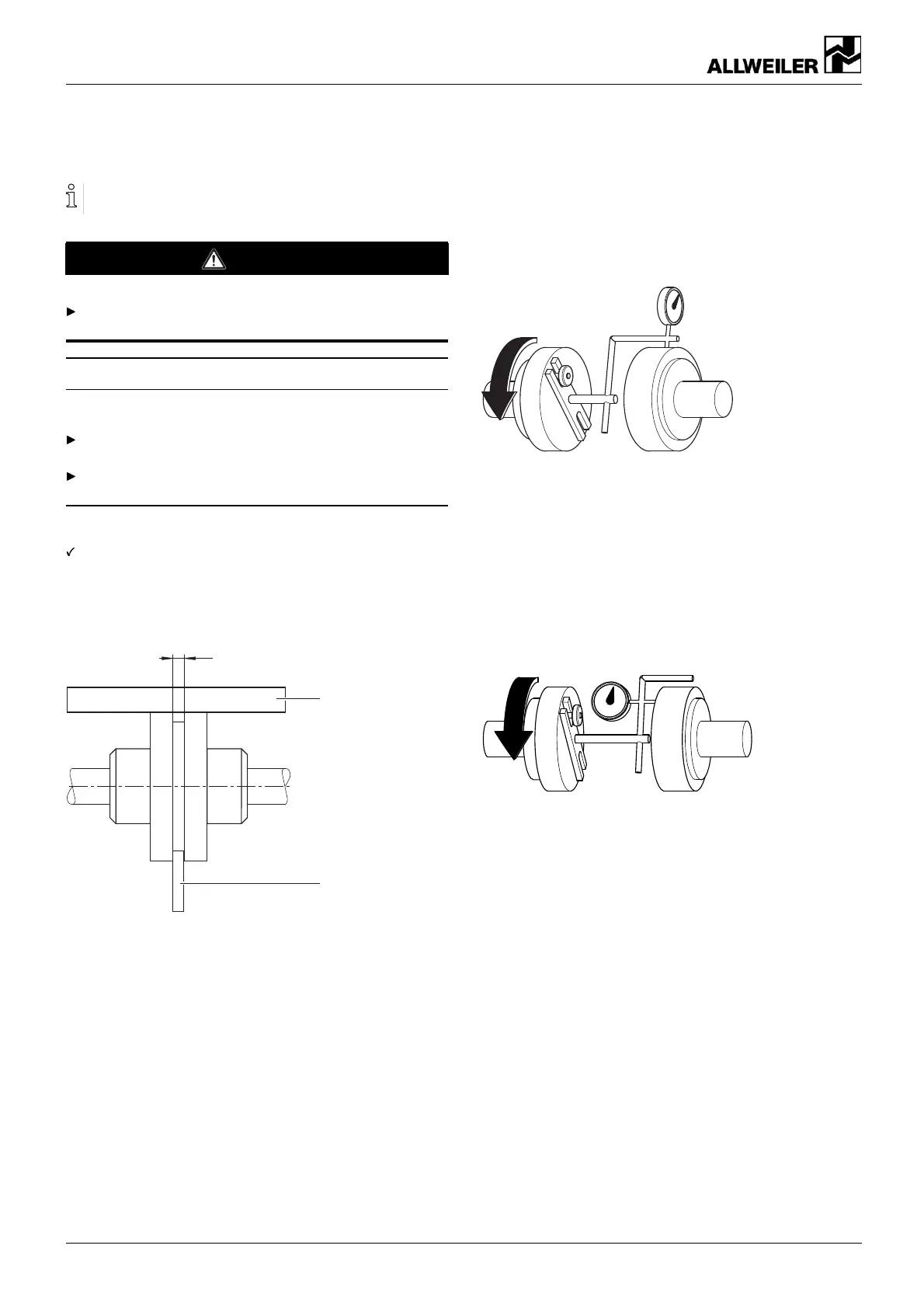

Fig. 14 Checking for angular displacement

5. Check th e angular disp lacement with a dial gauge:

– Carry out the measurement as illustrated.

– If there is any angular displacement: align the motor.

20 AE BA-2020.05 en-US 260371 – 176-982/0

Loading...

Loading...