Setup and connection

5.4.2 Sp ecifying nominal diameters

Keep the flow resistance in the pipes as low as possible.

1. Make sure the nominal suction pipe diameter is ≥ as pos-

sible to the nominal suction branch diameter.

– Recommended flowratespeed<1m/s

2. Make sure the nominal pressure pipe diameter is ≥ as pos-

sible to the no minal outle t flange diameter.

– Recommended flowratespeed<3m/s

5.4.3 Specifying pipe lengths

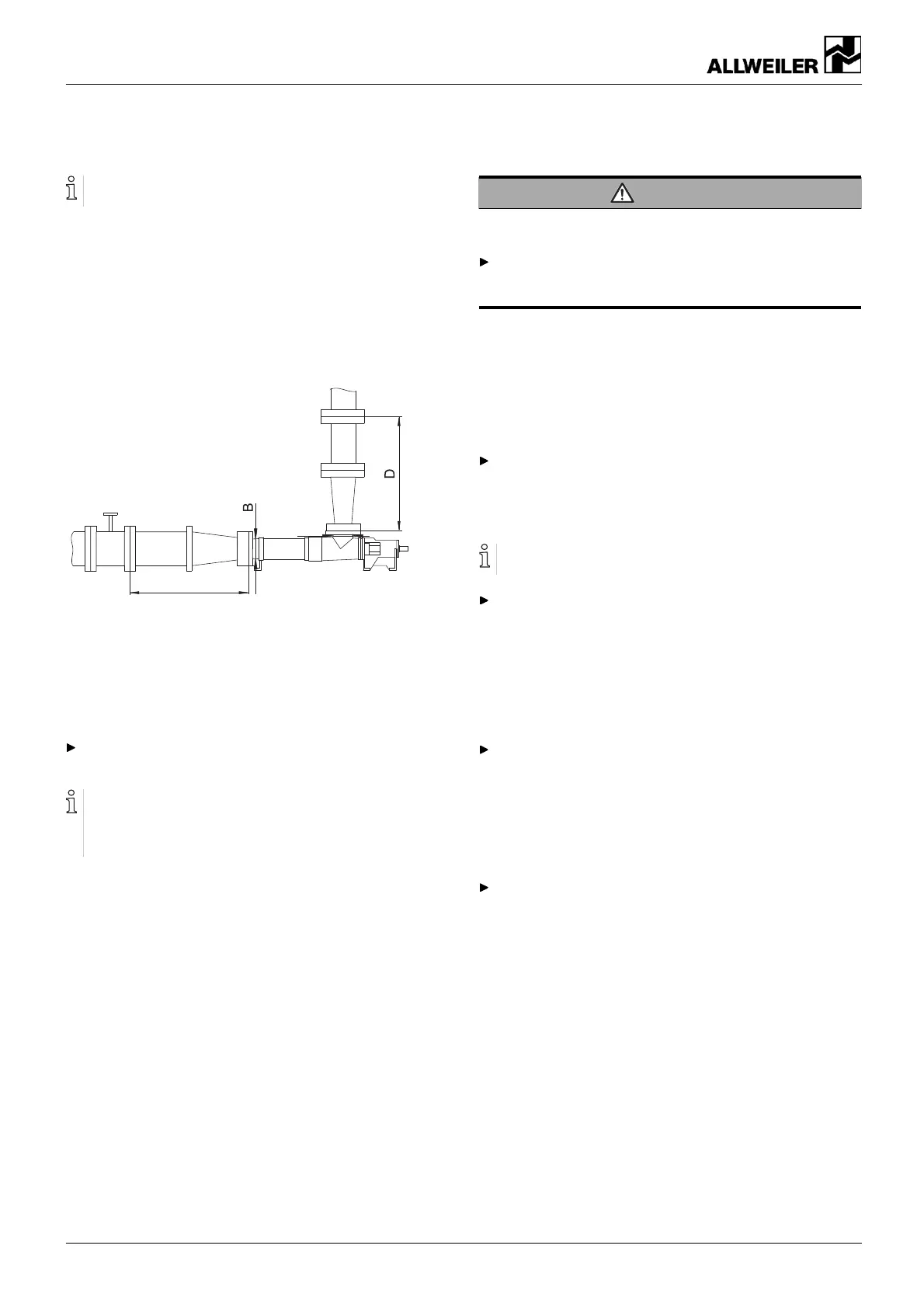

A

C

Fig. 11 Straight pipe lengths upstream and downstream

of the pump (recommended)

A > 5 x nominal pressure pipe diameter

B Nominal pressure pipe diameter

C Nominal suction pipe diameter

D > 5 x nominal suction pip e diameter

Maintain the recommended minimum va lues when

installing the pump.

Suction side: shorter pipes are possible but may restrict

the hydraulic perfor mance.

Pressure side: shorter pipes are possible b ut can result in

increased operating noise.

5.4.4 Optimizing changes in cross-section and

direction

1. Avoid bending radii of less than 1.5 times the nominal pipe

diameter.

2. Avoid abrupt change s of cross-se ction along th e piping.

5.4.5 Discha rging leaks

WARNING

Risk of injury and poisoning due to hazardous pumped

liquids!

Safely collect any leaking pumped liquid, then discharge

and dispose of it in accordance with en vironmental regula-

tions.

1. Provide equipment for c ollecting and discharging leaking

liquids.

2. Ensure the free discharge of leaking l iquids.

5.4.6 Pro viding safety and c ontrol devices

(recommended)

Avoiding reverse running

Install a non-return valve between the outlet flange and the

stop valve to ensure the medium does not flow back when

thepumpisswitchedoff.

Making provisions for isolating and shutting off pipes

For maintenance and repair work.

Provide shut-off devices in the suction an d pressure lines.

Allowing measurement of the operating conditions

1. Provide pressure gauges for pressure measurements in

the suction and pressure lines.

2. Provide for pu mp-side temperature measurements.

Providing dry-running protection

Provide suitable dry protection to protect the pump against

dry r unning and resulting damage:

– Select dry protection according to the speci fic applica-

tion.

– Select dry protection in co nsultation with the manufac-

turer.

Avoiding high pressures

To switch off the pump at high pressures, provi de suitable

shutdown devices, f or example, a pressure switch.

18 AE BA-2020.05 en-US 260371 – 176-982/0

Loading...

Loading...