Setup and connection

5.2 Installation on a foundation

NOTE

Material damage due to distortion of the base plate!

Place the base plate on the foundation and secure it as

described in the following.

5.2.1 Placing the pump unit on the foundation

Implements, tools and materials:

– Foundation bolts (→ setup drawing)

– Steel washers

– Non-shrinking mortar grout

– Spirit level

1. Lifting the pump unit (→ 4.1 Transport, Page 13).

2. Attach the foundation bolts from below into the base plate

fixing ho les.

Observe the manufacturer’s instructions when using adhe-

sive anchors.

3. Set the pump unit down on the foundation. When doing

so, sink the foundation bolts into the prepared anchoring

holes.

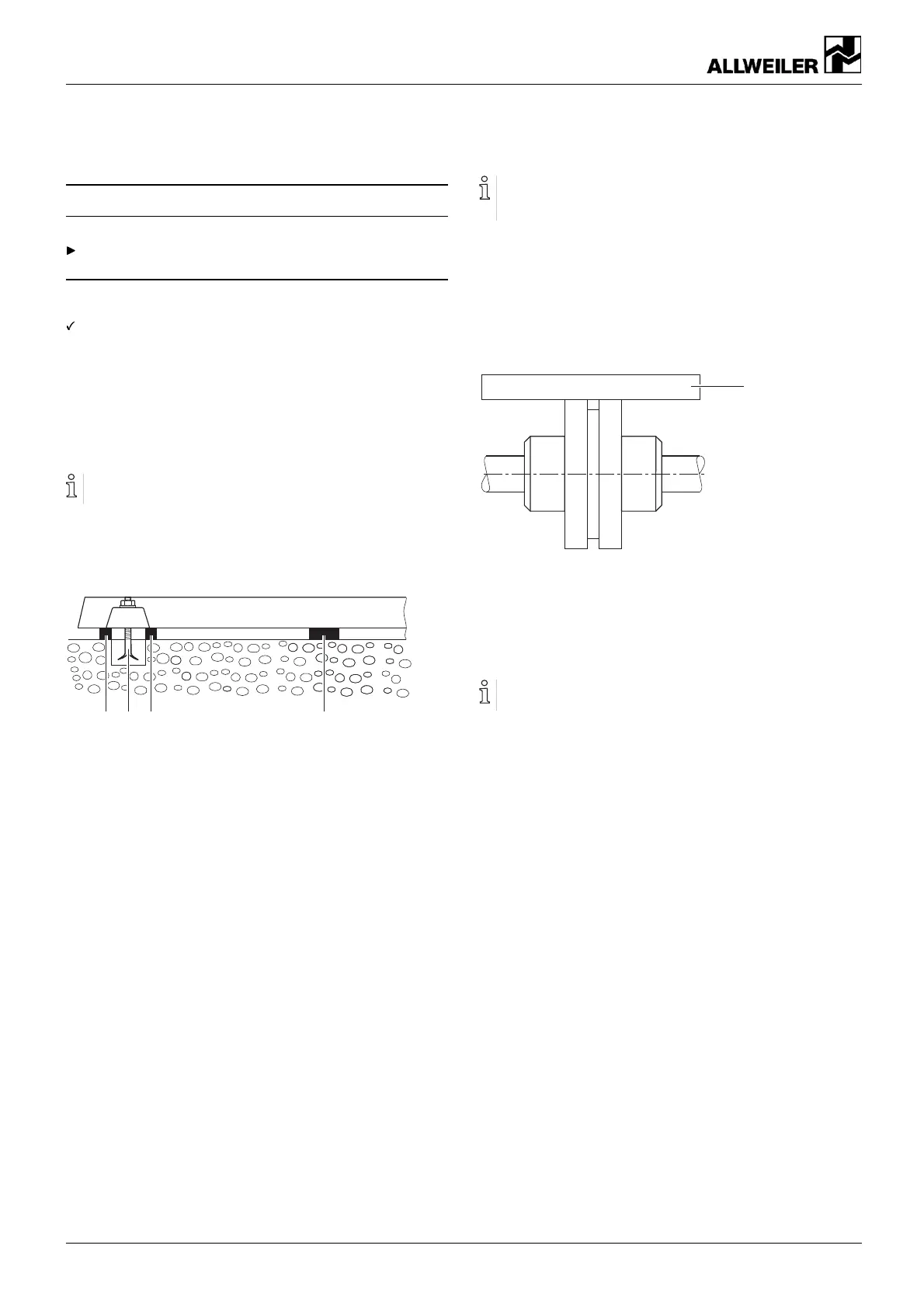

32 1 2

Fig. 10 Installation with foundation

4. Use stee l washers to align the pump unit to the height and

system dimensions as described in the following:

– Placeasteelwasher(2)totheleftandright-handside

of each foundation bolt (1).

– If the distance betwe en the anchoring hol es is greater

than 750 mm, place ad ditio nal steel washers (3) in the

middle, on each side of the base plate.

5. Make sure the steel washers lie flat against the base plate,

in full co ntact.

6. Use the integrated spirit level to check whether th e pump is

level end to end and side to side with a maximum allowable

tilt of 1 mm/m.

7. Repeat the procedure until the base plate is correctly

aligned.

5.2.2 Fastenin g the pump unit

The dampin g behavior is improved by filling the base plate

with mortar grout. When filling, isolate any present adjust-

ing screw for the engine he ight adjustment.

1. Fill the ancho ring holes with mortar grout.

2. When the mortar grout has set, screw down the base plate

at th ree points with t he specified torque.

3. Before tightening the remaining bolts, compensate for any

unevenness in the surface using metal spacing shims next

to each bolt.

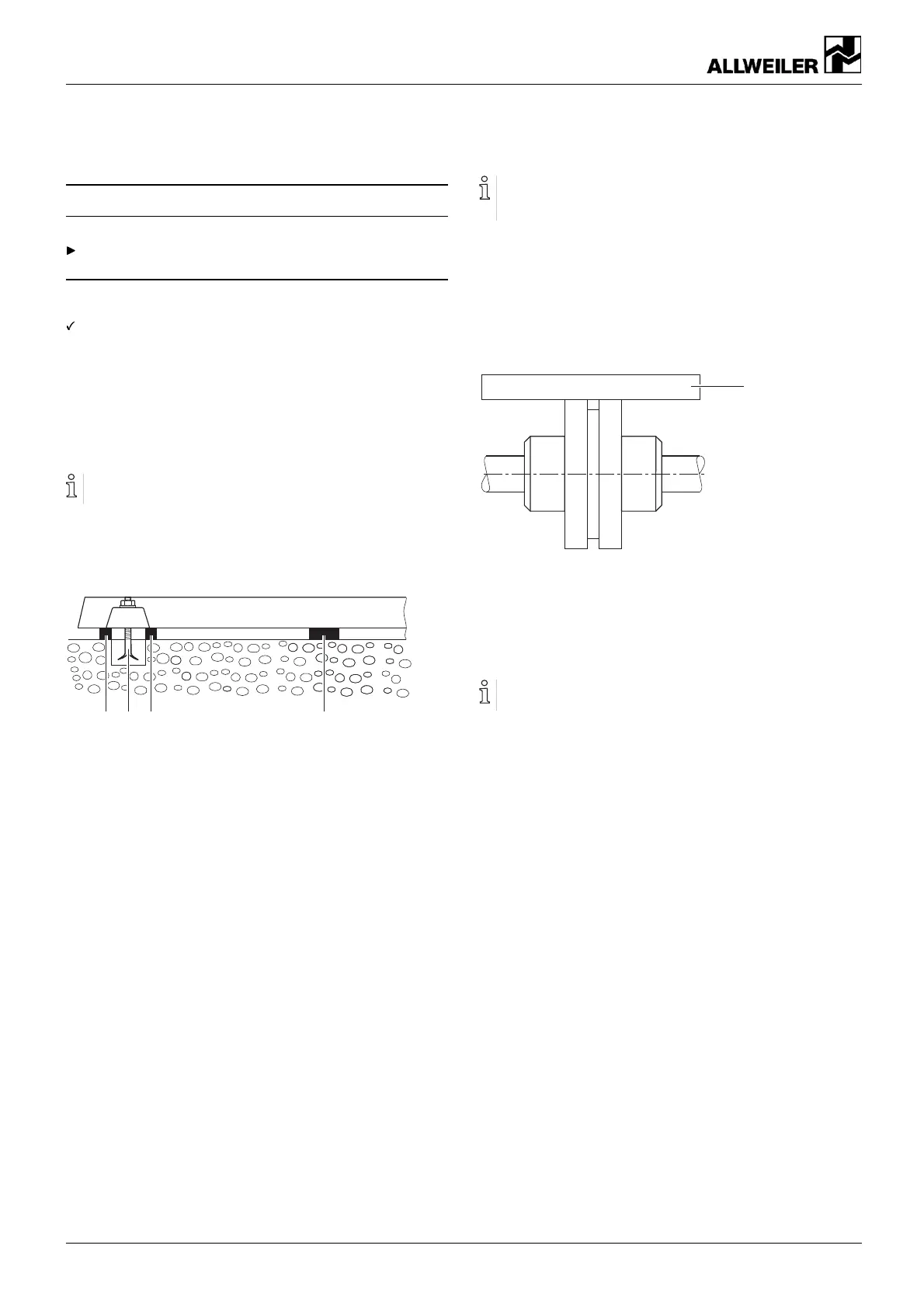

1

4. Check th e pump unit for any di stortion with a straightedge:

– Measure in two planes at an angle of 90° on the cir-

cumference of the coupling.

– Place the straightedge (1) over both coupling halves

and check the light gap at the outer diameter.

Couplings with s pacer piece (spacer coupling) can also be

checked with a dial gauge.

5. If there is signifi cant deviation, undo the fixing to the base

plate and correct the distortion by inserting more shims.

6. Fill the i nside of the base pl ate with concrete, if intended.

Knock on the base plate to ensure that no cavities are cre-

ated in the process.

16 AE BA-2020.05 en-US 260371 – 176-982/0

Loading...

Loading...