Appendix

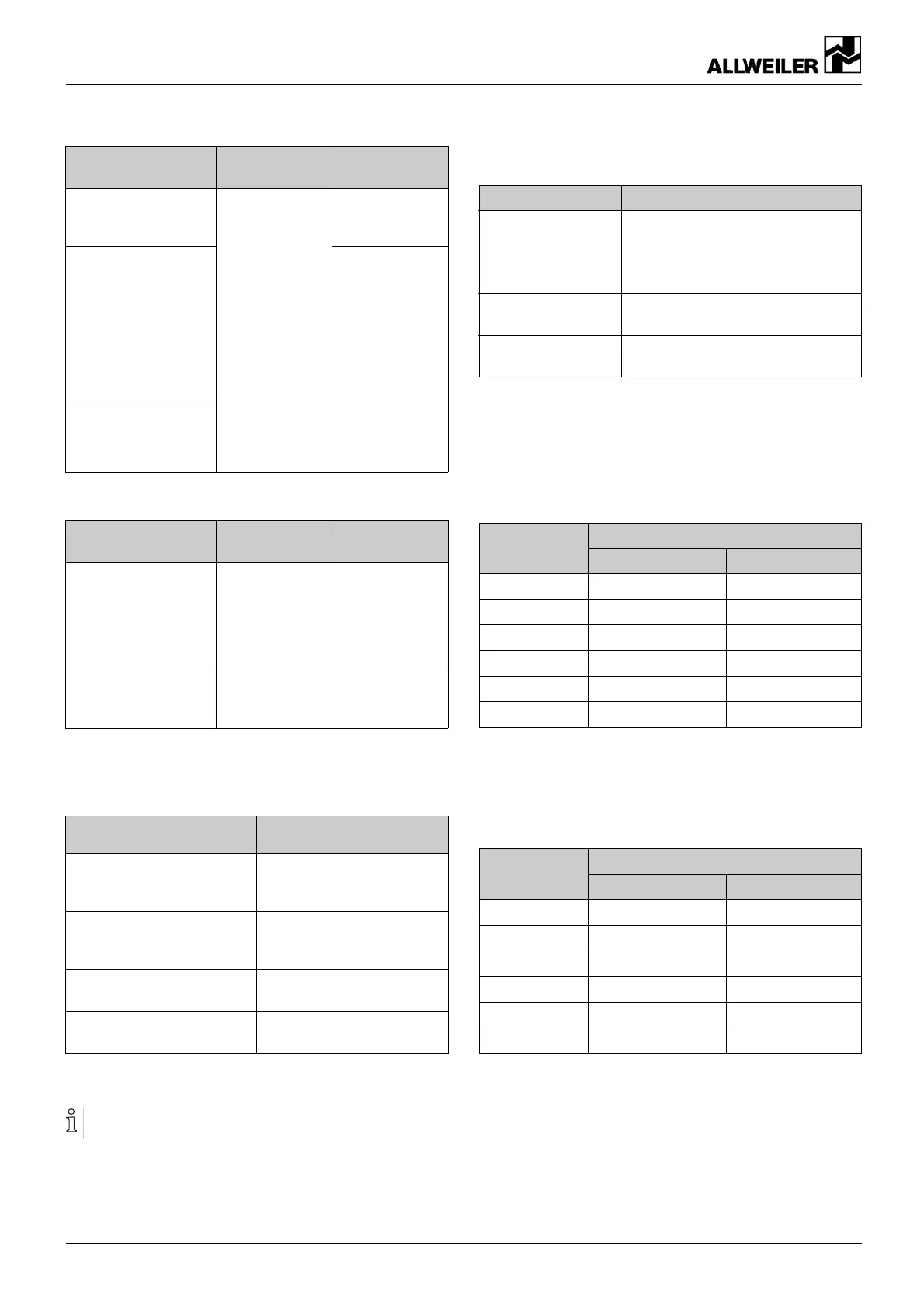

Parameter

Shaft seal

version

Values

Buffering medium

pressure

1.5–2.0 bar ove r

pressure in the

suction casing

Flow rate (regulation

takes place via

temperature values)

Exit

temperature

• ≤ 60 °C

• 30 K below

boiling

temperature

at working

pressure

Max. permissible

temperature

difference between

entry and exit

G0D/G1D

15 K

Tab. 19 Operating parameters for double-action

mechanical seal

Parameter

Shaft seal

version

Values

Max. permissible

pressure difference

between quench

medium pressure

and suction casing

pressure

0.5 bar

Max. permissible

quench medium

pressure

G0Q / G1Q

3bar

Tab. 20 Operating parameters for mechanical seal

with quenching

Operating parameters of the cooling and heating medium

Parameter Values

Type Liquid medium:

Must not cause corrosion of

the parts it contacts

Max. permissible cooli ng

and heating medium

pressure

6 bar

Max. permissible cooli ng

temperature

-40 °C

Max. pe rmissible hea ting

temperature

+150 °C

Tab. 21 Ope r ating parameters for th e cooling and

heating medium

The m inimum and maximum temperatures depend

on the

materials and lubricants used.

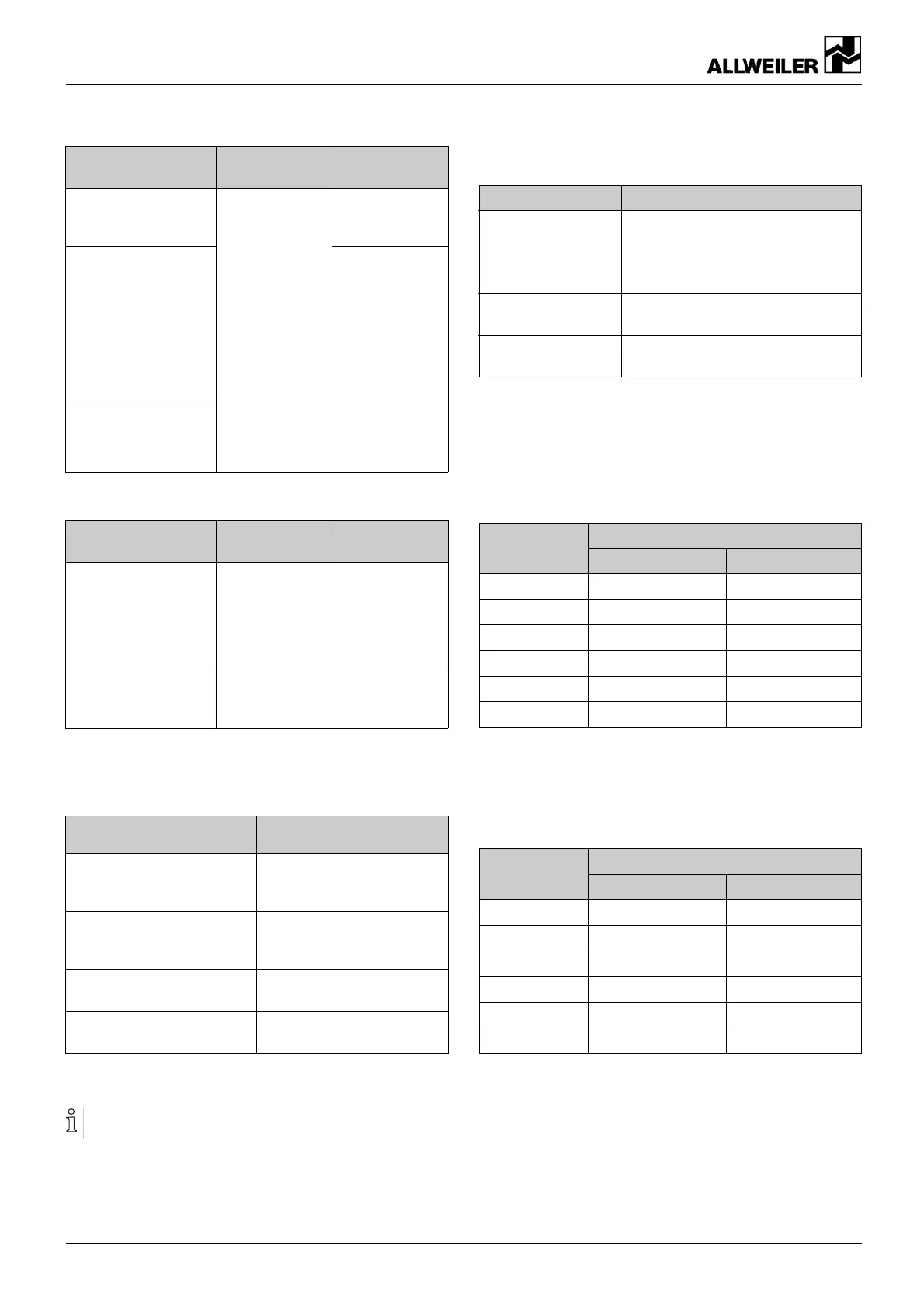

9.2.5 Lubrica nts

Lubrication point Lubricants

Joints of the

universal joint shaft

• ALLWEILER special joint oil

type B

• ALLWEILER special joint oil

type BL for food

Antifriction bearing

Rolling bearing greases accordin g

to DIN 51825, mark K3K-20

Spur gears Industrial g ear oil CLP 220 according

to DIN 51517, Part 3

Tab. 22 Lubricants

9.2.6 Lub rication quantities (RG design )

Gear oil for the spur gear

The mechan ics are described in the pump typ e identification

on the nameplate.

Lubrication quantity [l]

Size

N-mechanics H-mechanics

200 1.3 1.8

380 1.8 2.1

0750 2.5 4

1450 4.0

5.5

2700

7.5

13

5000 15

–

Tab. 23 Lubrication quantities for spur gea rs (RG)

Oil for the drive seal

The mechan ics are described in the pump typ e identification

on the nameplate.

Lubrication quantity [l]

Size

N-mechanics H-mechanics

200 0.05 0.12

380 0.12 0.12

0750 0.12 0.2

1450 0.2 0.2

2700 0.2 0.2

5000 0.2

–

Tab. 24 Lubric ation quantities f or drive seals (RG)

48 AE BA-2020.05 en-US 260371 – 176-982/0

Loading...

Loading...