Troubleshooting

8 Troubleshooting

8.1 Pump malfunctions

If malfunctions occur which are not specified in the following

table or canno t be traced back to the specifie d causes, please

consult the manufacturer.

Possible m alfunctions are identified by a number in the follow-

ing table. This number identifies the respective cause and rem-

edy in the troubleshooting list.

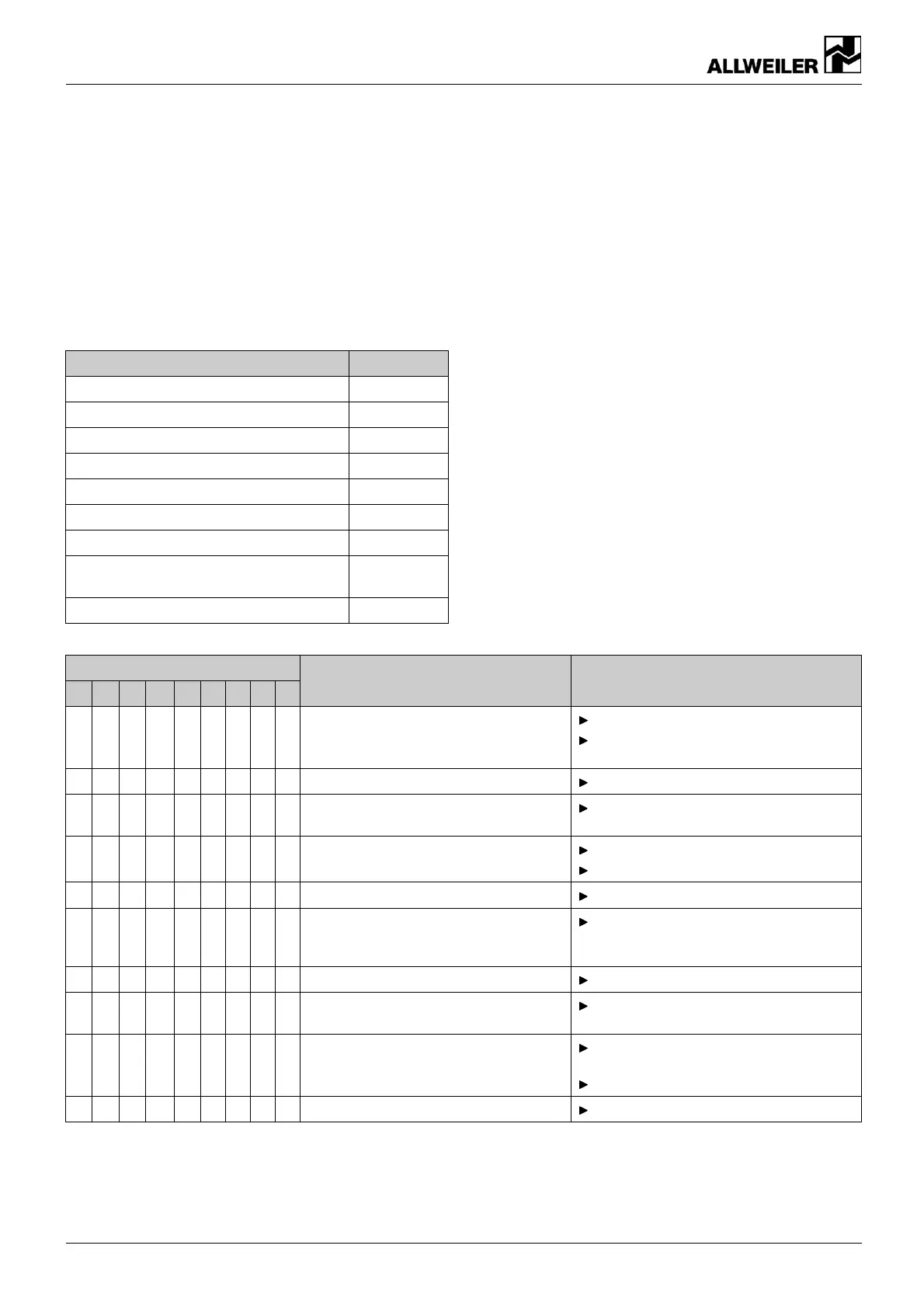

Malfunction

Number

Pump not pumping 1

Pumpingrateinsufficient

2

Pumping rate irregular or too high 3

No pump suction 4

Pump running roughly

5

Pump jammed 6

Pump leaking

7

Power consumption of the motor too

high/motor gets warm

8

Stator wears out pre m aturely

9

Tab. 9 Malfunction/number assignment

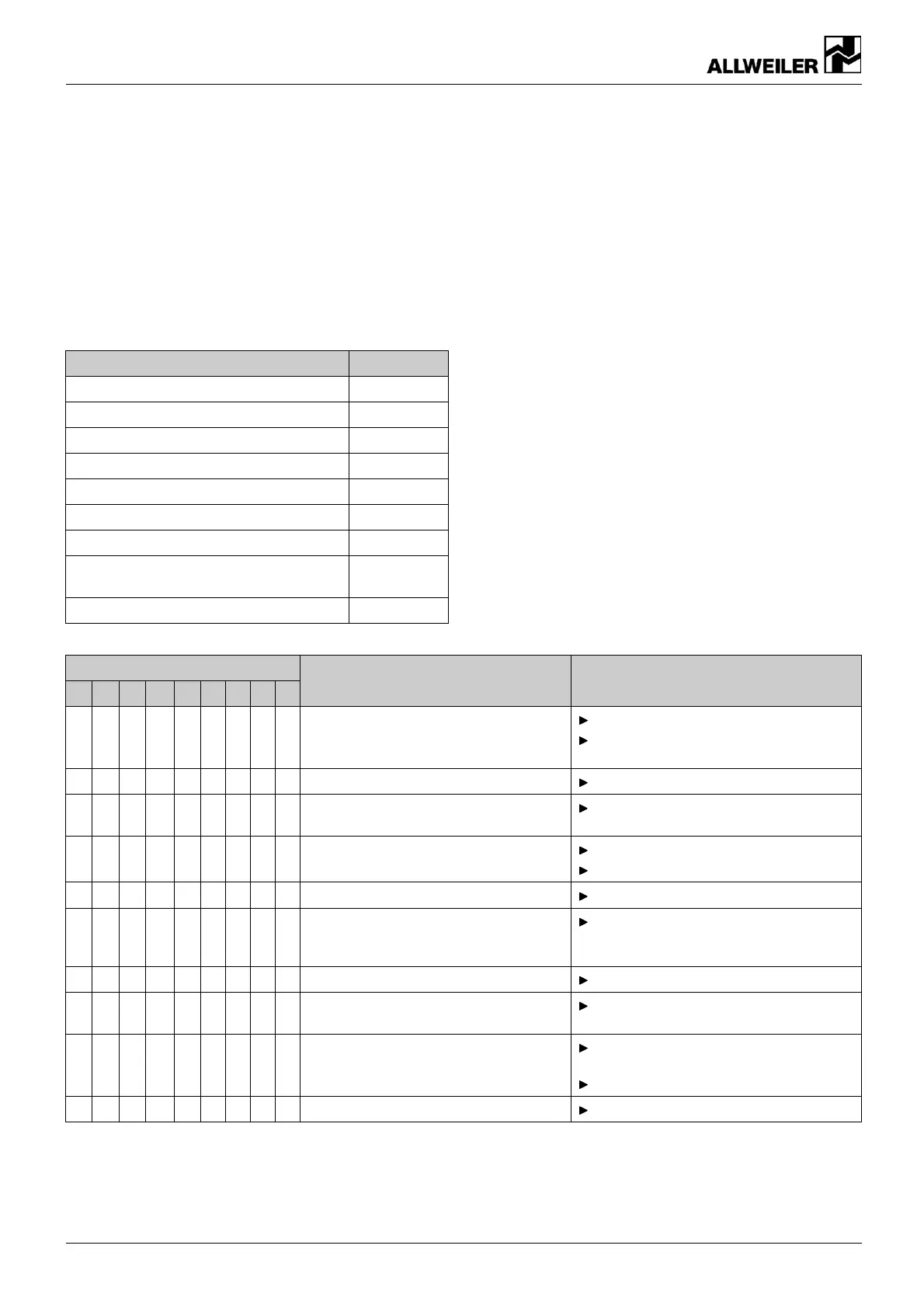

Malfunction number

12 34

5

6

7

89

Cause

Remedy

X

–––––––

Transp ort screw plugs still in place Remove the transport and sealing cover.

Dismount the pump and inspect it for

dry-running dam age.

X

–––––––

Supply/suction pip e closed by fitting

Open the fitting.

X

–––

X

–––

Supply/suction pipe not bled properly or

not filled up completely

Fill up the pump and/or piping completely

and bleed them.

X

–––

X

–––

Formation of air pockets in the sup ply or

suction pipe

Install the fitting for bleeding.

Correct the pipin g layout.

X

–––

X

–––

Pressure line blocked

Clean t he p ressu re line.

X

––

XX

–––

Pumprunninginthewrongsenseof

rotation

Swap any two phases on the motor

(→ 6.1.6 Checking the sense o f rotation,

Page 23).

X

––

X

–

X

––

Pump very dirty Dismount and clean the pump.

X

––––––

X

–

Packing gland bolted too tightly

Loosen the stuffing box gland on the

packing gland.

XX

–

XX

–––

Supply/suction p ipe , pump or suction

strainer blocked or en c rusted

Clean the supply/suction pi pe, pump or

suction strainer.

Clean the suction strainer.

XX

–

XX

–––

Air is sucked in

Seal the source of malfun cti on.

30 AE BA-2020.05 en-US 260371 – 176-982/0

Loading...

Loading...