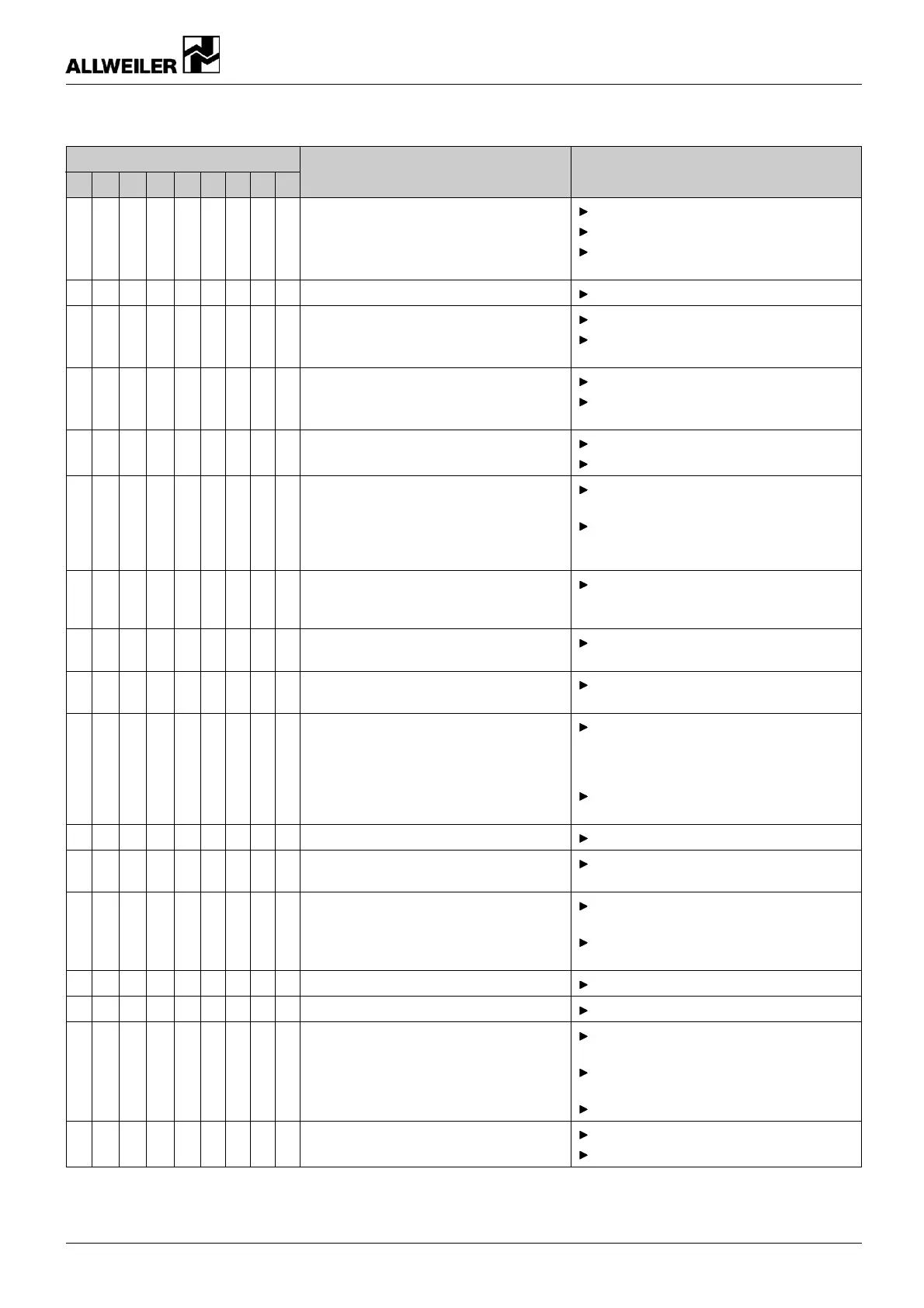

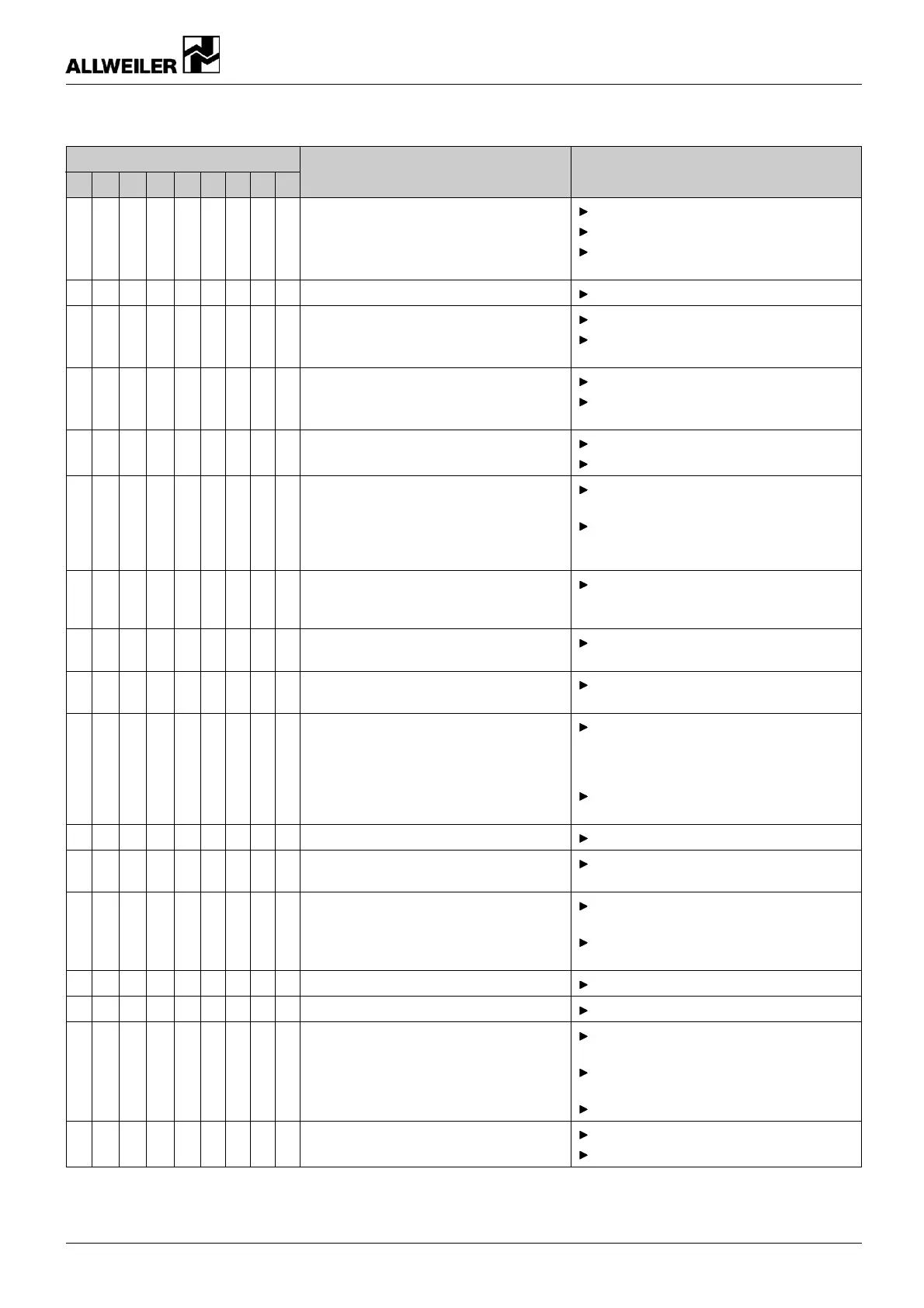

Troubleshooting

Malfunction number

12 34

5

6

7

89

Cause

Remedy

XX

–

XX

–––

Excessive amount of gas: pump is

cavitating

Check the cable gland.

Clean/enlarge the filter.

Enlarge the supply/suction pipe

cross-section.

XX

–

X

––

X

–

Shaft seal leaky

Replace the shaft seal.

XX

––

X

–

X

–

X Pump not heated, pumpe d liquid hardens Heat the pump.

Check the temperature of the liquid and

adjust it if necessary.

XX

––

X

––

X

–

Solids content too large, grain size too

large

Reduce speed.

Install strai ner with the permitted mesh

size in the suction pipe.

XX

–– ––

X

–

X

Solids sediment in the liquid during a lon g

standstill

Flush the pump.

Dismantle an d clean the pump.

XX

––

XX

–

X

–

Pumped liquid temp erature too high

Stator expansion t oo large, stator burned

or swollen

Check the temperature of the liquid and

adjust it if necessary.

Allow the pump to cool down and check

that rotor can move freely. If necessary,

remove pump and repl ace the stator.

XX

–

X

––

XX

–

Foreign particles in the pump

Check pump for foreign particles. If

necessary, disassemble the pump and

remove foreign particles.

X

––––––

X

–

Adhesion between the rotor and stator

Turn the pump by hand, use aids if

necessary.

–

XXXX

––––

Suction pipe and shaft seal leaky

Check suction pipe and shaft seal for

leaks.

–

X

–

X

––––

Motor speed too low

Compare the required motor speed

with the specifications on the pump

nameplate. Replace the motor if

necessary.

Increase the motor s peed if speed

control is available.

–

X

–

X

––––

Supply/suction pipe not fully opened

Open the fitting.

–

X

–

X

–––––

Low speed for liquids w ith low viscosity

and high suction volume

Increase speed.

–

X

–

X

––

X

––

Packing gland not tightened or packing

rings worn

Tighten the stuffing box gland on the

packing gland.

Check packing rings and replace if

damaged/worn.

–

X

–

X

–

X

––

X

No liquid in the feed/suction pipe

Ensure inflow of pumped liquid.

–

XXX

–––––

Pumped liquid viscosity too high

Check the viscosity of the pumped liquid.

–

X

–

XX

–––

Supply/suction pipe cross-section too

narrow

Enlarge the supply/suction pipe

cross-section.

Remove any encrustatio ns from the

suction pipe.

Open the fitting completely.

–

X

–

XX

–––

Suction head excessive:

NPSH

pump

larger than NPSH

system

Increase the suction pressure.

Consult the manufacturer.

260371 – 176-982/0 BA-2020.05 en-US AE 31

Loading...

Loading...