Installation and Start Up

| 3-29

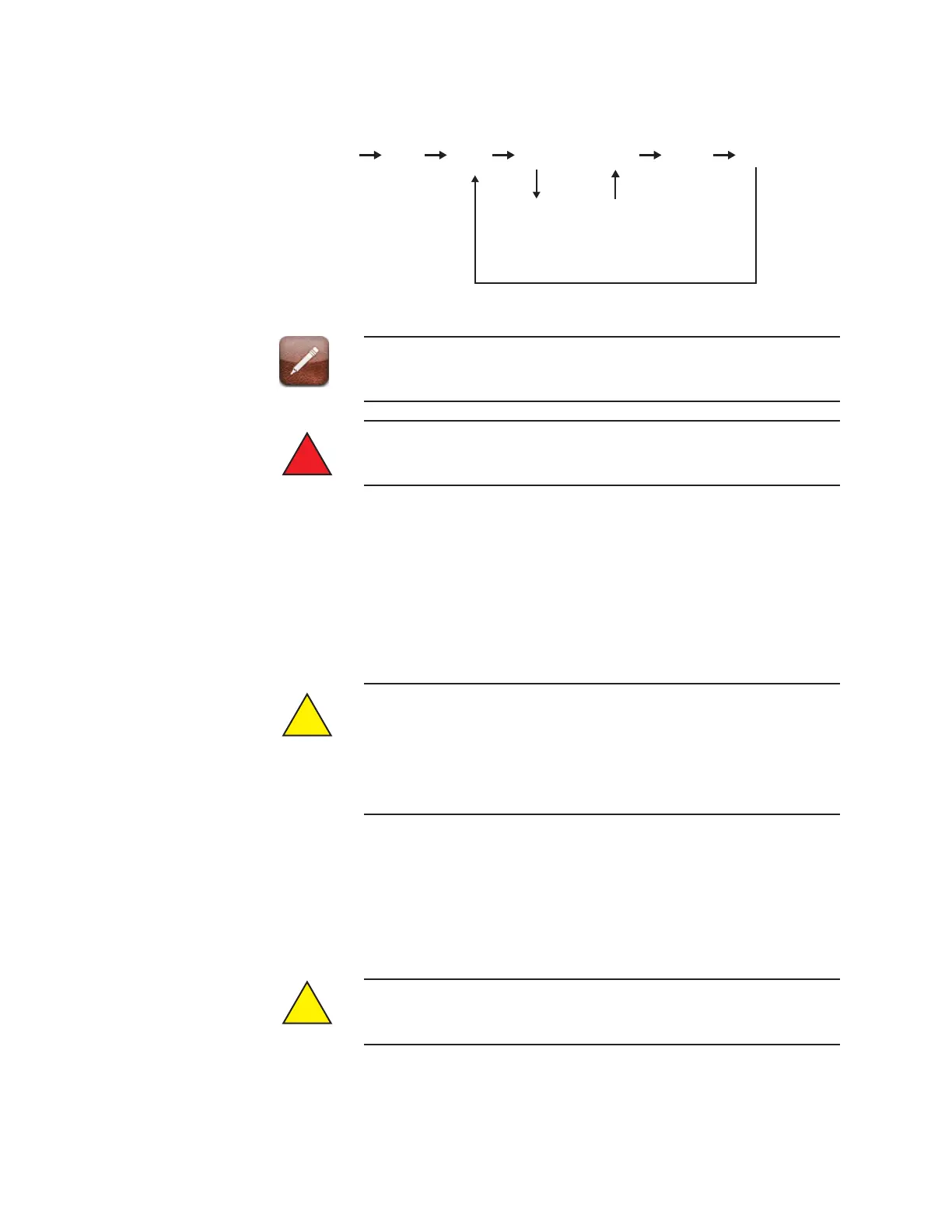

Periodic STEAM BLOW BACK Diagram

Per1 Per2 Per5 Per6 Per9 Per10

Per11

Blowback Timer times OUT

and Zero Period<> 0

If using the automatic steam blowback function, do not set Blowback

Interval to a value less than 16 or run the cycle more than once a day.

If your analyzer requires steam blowback to run more than once a

day, please contact the Ametek Service Department.

Calibration Span Adjustment

The Model 888 has an optional calibration span adjustment that is per-

formed manually. Use cylinders of H

2

S and SO

2

of known concentrations

to validate and/or adjust the calibration of the analyzer.

Potentially lethal concentrations of toxic gases such as hydrogen

sulfide (H

2

S) and sulfur dioxide (SO

2

) will be present in the ana-

lyzer sample system and in the calibration gas supply system. Only

personnel who are adequately trained in the handling of these gases

should perform this procedure.

Calibration Gas Requirements

Recommended calibration gas mixtures are H

2

S in nitrogen and SO

2

in

nitrogen (as separate mixtures). H

2

S or SO

2

concentration should be about

80% of the full-scale measuring range for that component. The delivery

pressure for the calibration gas should be adjustable from 0 to 10 psig.

Calibration gas mixtures more than six months old are unreliable and

should not be used.

!

WARNING

!

!

Loading...

Loading...